Preparation method and application of nanometer zero-valence bimetal-supported functional charcoal

A nano-zero-valent, biochar technology, applied in chemical instruments and methods, water pollutants, other chemical processes, etc., to achieve the effect of simple preparation method, uniform distribution, and improved porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

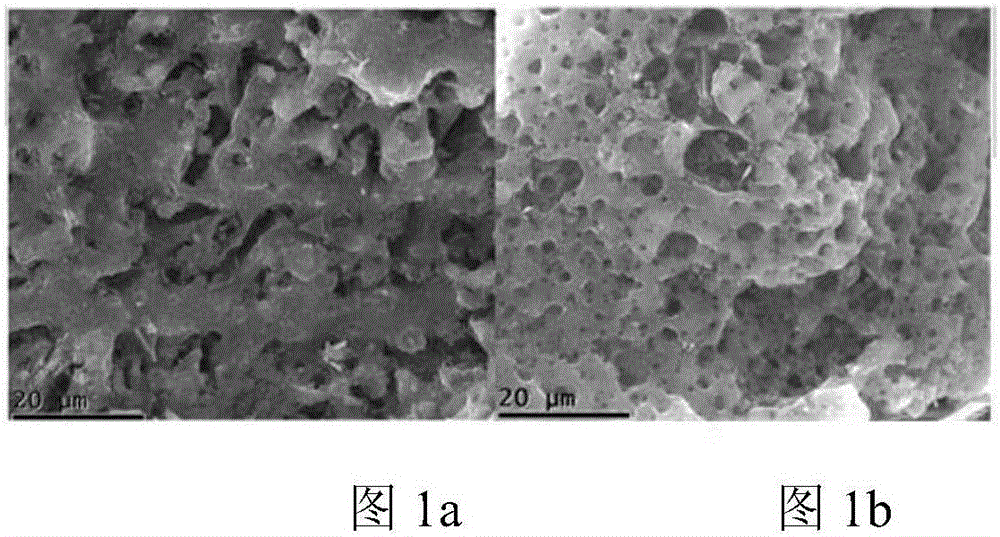

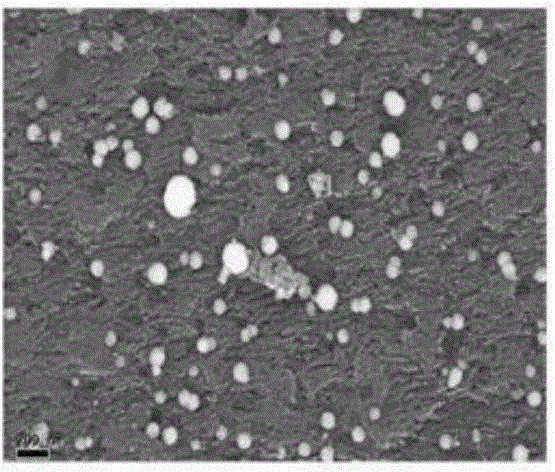

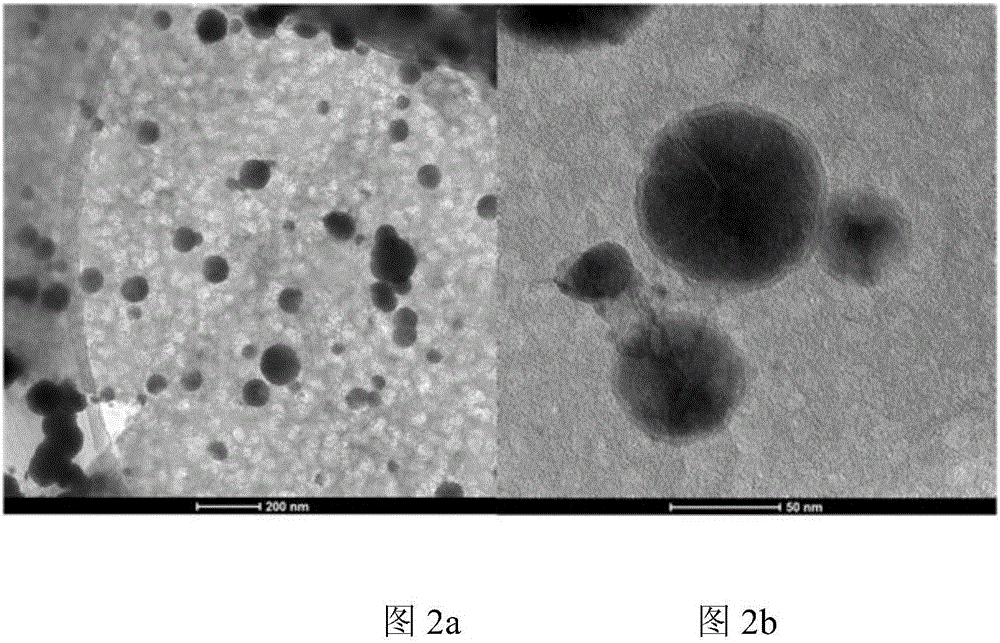

[0026] In this preparation method, the biochar modified by sodium hydroxide is used as the carrier, and the nanometer zero-valent metal iron and silver are used as the active components. The active components are loaded on the carrier by impregnation and liquid phase reduction. The amount is 0.1-15wt% of the weight of the functional biochar, and it is prepared to load nano-sized zero-valent bimetallic functional biochar; including the following steps:

[0027] 1) After washing and drying the biochar, immerse it in 1~8mol·L -1 Sodium hydroxide solution, with a solid-to-liquid ratio of 1:1 to 1:10, continuously stirred for 6 to 12 hours at a temperature of 50°C to 80°C to obtain modified biochar, washed with a large amount of primary water until nearly neutral, filtered, Dry and store at 85°C for later use;

[0028] 2), weigh 2g of ferrous sulfate and polyethylene glycol and dissolve in ethanol aqueous solution, the mass ratio of described ferrous sulfate and polyethylene glyco...

Embodiment 1

[0035] Embodiment 1: A kind of preparation method of loaded nanometer zero-valent bimetal functional biochar, comprises the following steps:

[0036] 1) After cleaning and drying the original biochar, immerse it in 1mol·L -1 Sodium hydroxide solution, with a solid-to-liquid ratio of 1:10, continued stirring for 6 hours at a temperature of 50°C to obtain modified biochar, filtered and washed with a large amount of primary water until it was nearly neutral, dried at 85°C and stored for later use.

[0037] 2) Weigh 2g of ferrous sulfate and polyethylene glycol (mass ratio: 40:1) and dissolve in aqueous ethanol (volume ratio: 1:1). The weighed and dried modified biochar was submerged in the mixed system of ferrous sulfate and polyethylene glycol, and ultrasonicated for 1 hour with a power of 200W.

[0038] 3) Prepare 60mL0.4mol L -1 Sodium borohydride solution was titrated into the biochar-ferrous sulfate-polyethylene glycol mixed system at a rate of 3mL per minute, the reaction...

Embodiment 2

[0041] Embodiment 2: a kind of preparation method of loaded nanometer zero-valent bimetal functional biochar, comprises the following steps:

[0042] 1) After cleaning and drying the original biochar, immerse it in 4mol·L -1 Sodium hydroxide solution with a solid-to-liquid ratio of 1:5, continuously stirred for 8 hours at 60°C to obtain modified biochar, filtered and washed with a large amount of primary water until nearly neutral, dried at 85°C and stored for later use.

[0043] 2) Weigh 2g of ferrous sulfate and polyethylene glycol (mass ratio: 100:1) and dissolve in aqueous ethanol (volume ratio: 2:1). The weighed and dried modified biochar was immersed in the mixed system of ferrous sulfate and polyethylene glycol, and ultrasonicated for 2 hours with a power of 350W.

[0044] 3) Prepare 60mL0.8mol L -1 Sodium borohydride solution was titrated into the biochar-ferrous sulfate-polyethylene glycol mixed system at a rate of 2mL per minute, the reaction temperature was 10°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Equilibrium adsorption | aaaaa | aaaaa |

| Equilibrium adsorption | aaaaa | aaaaa |

| Equilibrium adsorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com