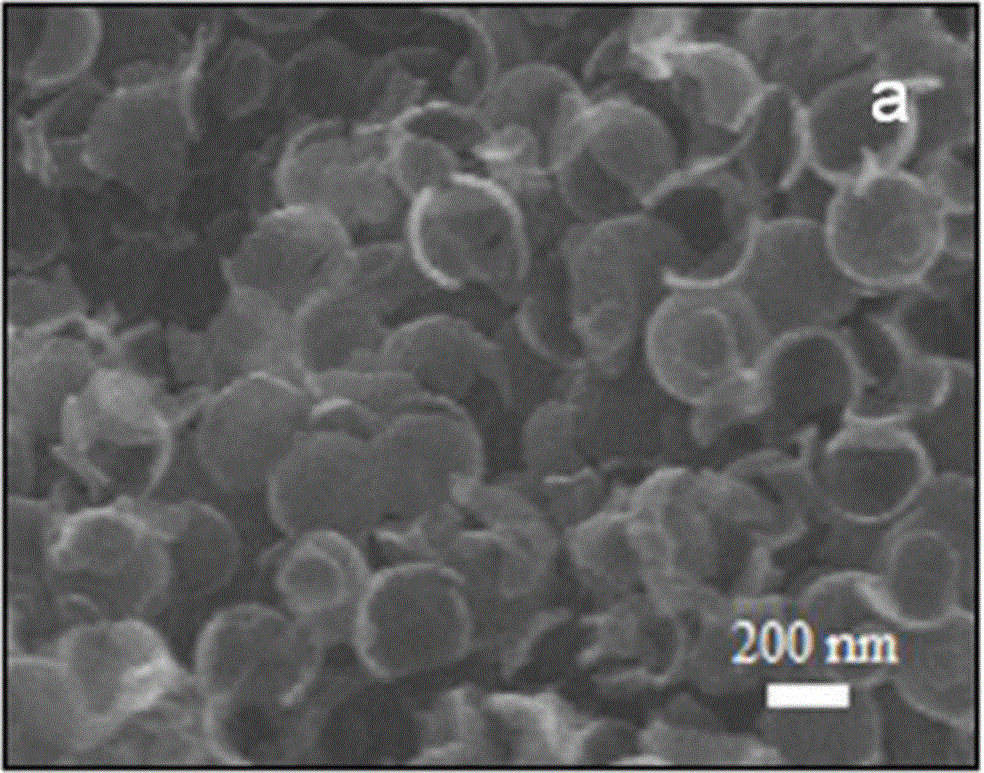

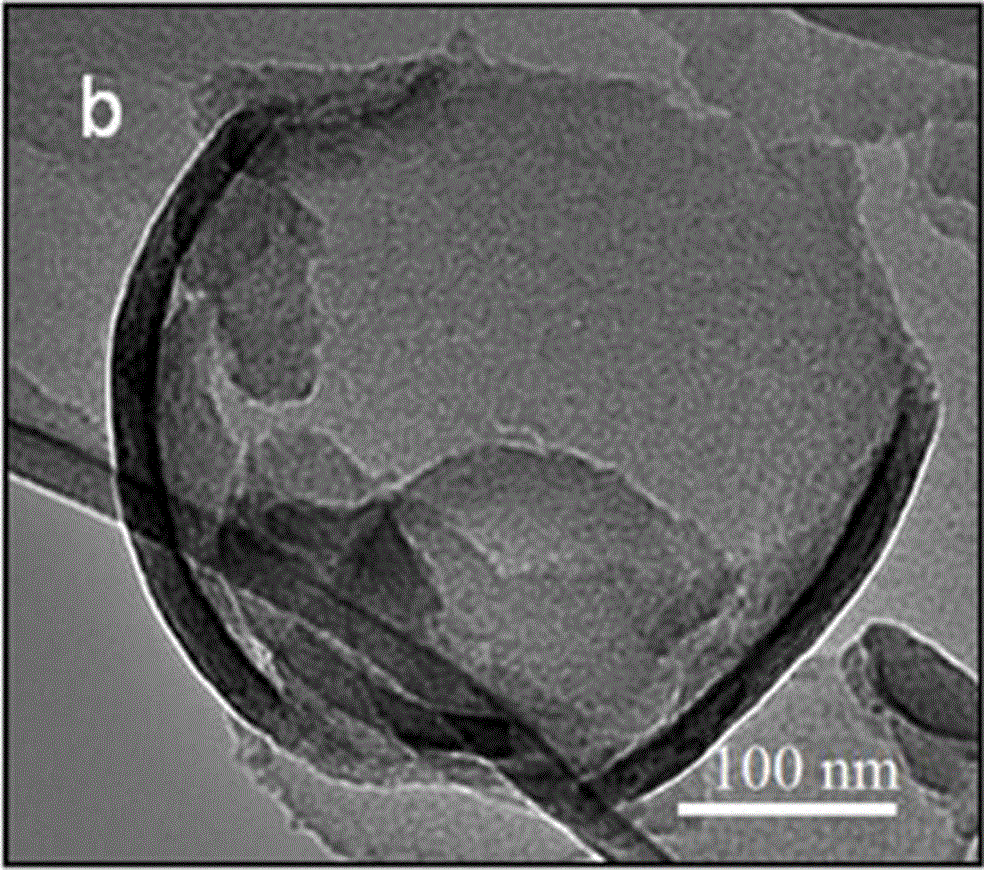

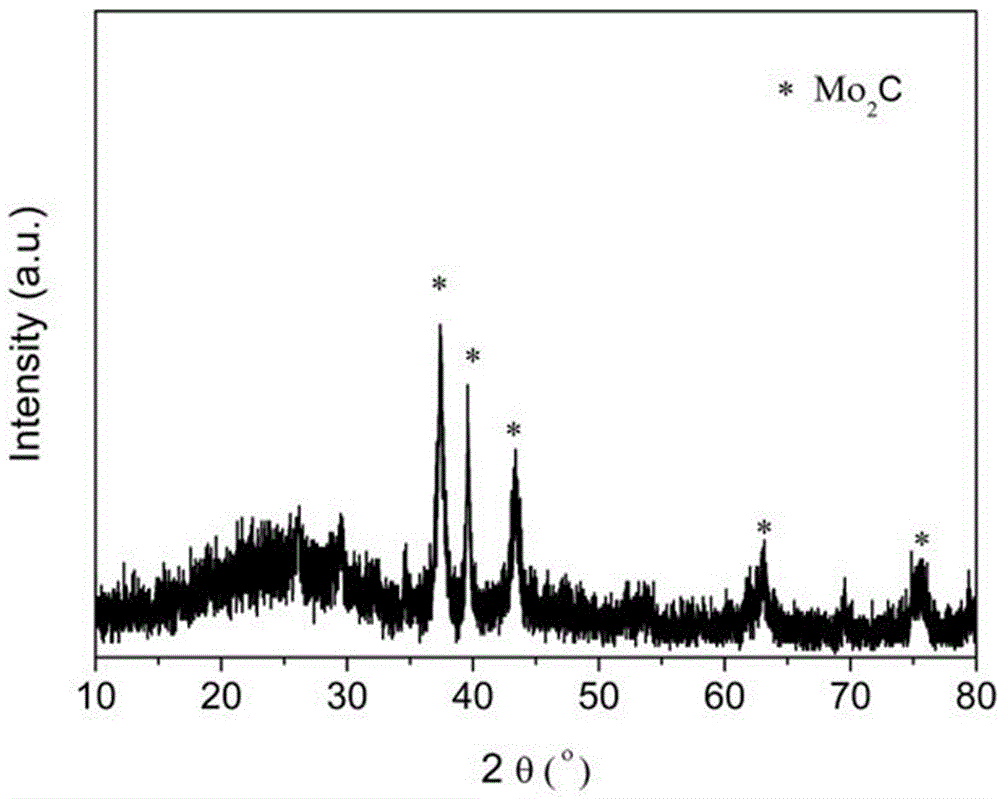

Preparation method of bowl-shaped carbon-molybdenum carbide composite material

A composite material and molybdenum carbide technology, which is applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of complex preparation of precursors, large product particles, large particles, etc., and achieve process parameters that are easy The effect of control, simple preparation process and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A kind of preparation method of bowl-shaped carbon and molybdenum carbide composite material, it is realized by following steps:

[0016] (1) Fully dissolve cetyltrimethylammonium bromide in a mixture of ethanol and water with a volume ratio of 1:2 to form a 0.6g / L cetyltrimethylammonium bromide solution, add Silica micro-nanospheres with a molar ratio of 0.3:6 to cetyltrimethylammonium bromide, after uniform dispersion, add p-benzene with a molar ratio of 0.1:1.5 to cetyltrimethylammonium bromide Diphenol, then add formaldehyde solution, the molar ratio of formaldehyde in the described cetyltrimethylammonium bromide and formaldehyde solution is 0.6:5; Then add and cetyltrimethylammonium bromide molar ratio is 0.3: 14 hydrazine hydrate, finally add ammonium molybdate with a molar ratio of 0.1:3 to cetyltrimethylammonium bromide, stir at room temperature for 18 hours, and dry to obtain a solid powder;

[0017] (2), the solid powder obtained in step (1) was heated at 700...

Embodiment 2

[0020] A kind of preparation method of bowl-shaped carbon and molybdenum carbide composite material, it is realized by following steps:

[0021] (1) Fully dissolve cetyltrimethylammonium bromide in a mixture of ethanol and water with a volume ratio of 1:2 to form a 2g / L cetyltrimethylammonium bromide solution, add Silica micro-nanospheres with a molar ratio of cetyltrimethylammonium bromide of 0.6:5, after uniform dispersion, add m-phthalamide with a molar ratio of 0.3:2 to cetyltrimethylammonium Phenol, then add formaldehyde solution, the molar ratio of formaldehyde and cetyltrimethylammonium bromide in the said formaldehyde solution is 0.1:8; hydrazine hydrate, and finally add phosphomolybdic acid with cetyltrimethylammonium bromide molar ratio of 0.3: 6, after stirring at room temperature for 15h, dry to obtain solid powder;

[0022] (2), the solid powder obtained in step (1) was heated at 800 o Calcining for 3 hours under C to obtain the first product of the composite ma...

Embodiment 3

[0025] A kind of preparation method of bowl-shaped carbon and molybdenum carbide composite material, it is realized by following steps:

[0026] (1) Fully dissolve cetyltrimethylammonium bromide in a mixture of ethanol and water with a volume ratio of 1:2 to form a 4g / L cetyltrimethylammonium bromide solution, add Silica micronanospheres with cetyltrimethylammonium bromide molar ratio of 0.1:5.5, after uniform dispersion, add phthalic trimethylammonium bromide with cetyltrimethylammonium bromide molar ratio of 0.6:0.9 Phenol, then add formaldehyde solution, the molar ratio of formaldehyde and cetyltrimethylammonium bromide in the said formaldehyde solution is 0.3:10; hydrazine hydrate, finally added phosphomolybdic acid in a molar ratio of 0.6:1 to cetyltrimethylammonium bromide, stirred at room temperature for 17 hours, and dried to obtain a solid powder;

[0027] (2), the solid powder obtained in step (1) was heated at 900 o Calcining for 3 hours under C to obtain the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com