Chitosan/polyurethane composite material and method for preparing same

A composite material and chitosan technology, applied in the field of organic materials, can solve the problems of poor wet mechanical properties and limited application of chitosan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The chitosan / polyurethane composite material described in this embodiment includes the following components in parts by weight: 38 parts of chitosan, 16 parts of polyurethane, 4 parts of polypropylene, 2 parts of potassium magnesium phosphate, 3 parts of dragite, seaweed 6 parts of sodium bicarbonate, 3 parts of barium carbonate, 5 parts of tripropylene glycol diacrylate, 3 parts of phosphate methacrylate, 5 parts of polyglycerol ricinoleate, 1 part of ammonium molybdate, ethylenediamine tetramethylene phosphine 3 parts of sodium phosphate, 2 parts of methyl orthosilicate, 2 parts of tea saponin, 58 parts of acetic acid and 76 parts of water.

[0022] The molecular weight of the chitosan is 5000-30000.

[0023] The preparation method of chitosan / polyurethane composite material described in the present embodiment may further comprise the steps:

[0024] (1) Add chitosan to acetic acid, stir to dissolve, and dialyze in distilled water overnight;

[0025] (2) Add potassi...

Embodiment 2

[0029] The chitosan / polyurethane composite material described in the present embodiment comprises the components of the following parts by weight: 55 parts of chitosan, 27 parts of polyurethane, 9 parts of polypropylene, 7 parts of potassium magnesium phosphate, 8 parts of dragite, seaweed 13 parts of sodium bicarbonate, 9 parts of barium carbonate, 11 parts of tripropylene glycol diacrylate, 10 parts of phosphate methacrylate, 11 parts of polyglycerol ricinoleate, 5 parts of ammonium molybdate, ethylenediamine tetramethylene phosphine 8 parts of sodium phosphate, 6 parts of methyl orthosilicate, 10 parts of tea saponin, 70 parts of acetic acid and 90 parts of water.

[0030] The molecular weight of the chitosan is 5000-30000.

[0031] The preparation method of chitosan / polyurethane composite material described in the present embodiment may further comprise the steps:

[0032] (1) Add chitosan to acetic acid, stir to dissolve, and dialyze in distilled water overnight;

[003...

Embodiment 3

[0037] The chitosan / polyurethane composite material described in the present embodiment comprises the following components in parts by weight: 46 parts of chitosan, 21 parts of polyurethane, 6 parts of polypropylene, 4 parts of potassium magnesium phosphate, 5 parts of dragite, seaweed 10 parts of sodium bicarbonate, 6 parts of barium carbonate, 8 parts of tripropylene glycol diacrylate, 6 parts of methacrylate phosphate, 8 parts of polyglycerol ricinoleate, 3 parts of ammonium molybdate, ethylenediamine tetramethylene phosphine 5 parts of sodium phosphate, 4 parts of methyl orthosilicate, 6 parts of tea saponin, 64 parts of acetic acid and 78 parts of water.

[0038] The molecular weight of the chitosan is 5000-30000.

[0039] The preparation method of chitosan / polyurethane composite material described in the present embodiment may further comprise the steps:

[0040] (1) Add chitosan to acetic acid, stir to dissolve, and dialyze in distilled water overnight;

[0041] (2) A...

PUM

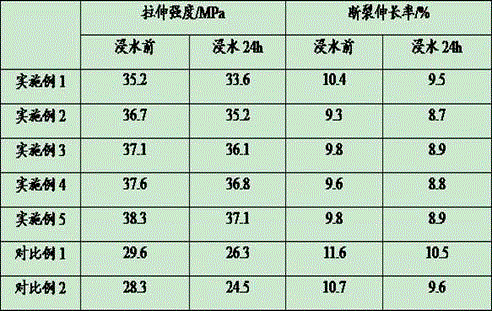

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com