A kind of fluorine-based blue fluorescent powder and preparation method thereof

A blue phosphor, fluoride technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of poor comprehensive performance of blue phosphors, and achieve good physical and chemical properties, pollution-free, and environment-friendly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Preparation of Sr 7 Y 5.9994 Ce 0.0006 OF 30

[0028] According to the chemical formula Sr 7 Y 5.9994 Ce 0.0006 OF 30 The stoichiometric ratio of each element in the formula is weighed as strontium fluoride SrF 2 : 2.1983 g, yttrium oxide Y 2 o 3 : 1.6934 g, cerium oxide CeO 2 : 0.0003 g, after grinding and mixing well in an agate mortar, buried in 4.6702 g of ammonium fluoride NH 4 In F, select a reducing atmosphere for pre-calcination, the pre-calcination temperature is 450°C, and the pre-calcination time is 14 hours, then cool to room temperature, and take out the sample; the pre-calcined sample is fully mixed and ground again, and buried in 4.6702 grams of fluoride Ammonium NH 4 In F, the final calcination is carried out in a reducing atmosphere, the calcination temperature is 1350° C., the calcination time is 2 hours, and it is naturally cooled to room temperature, and the sample is taken out to obtain the blue phosphor.

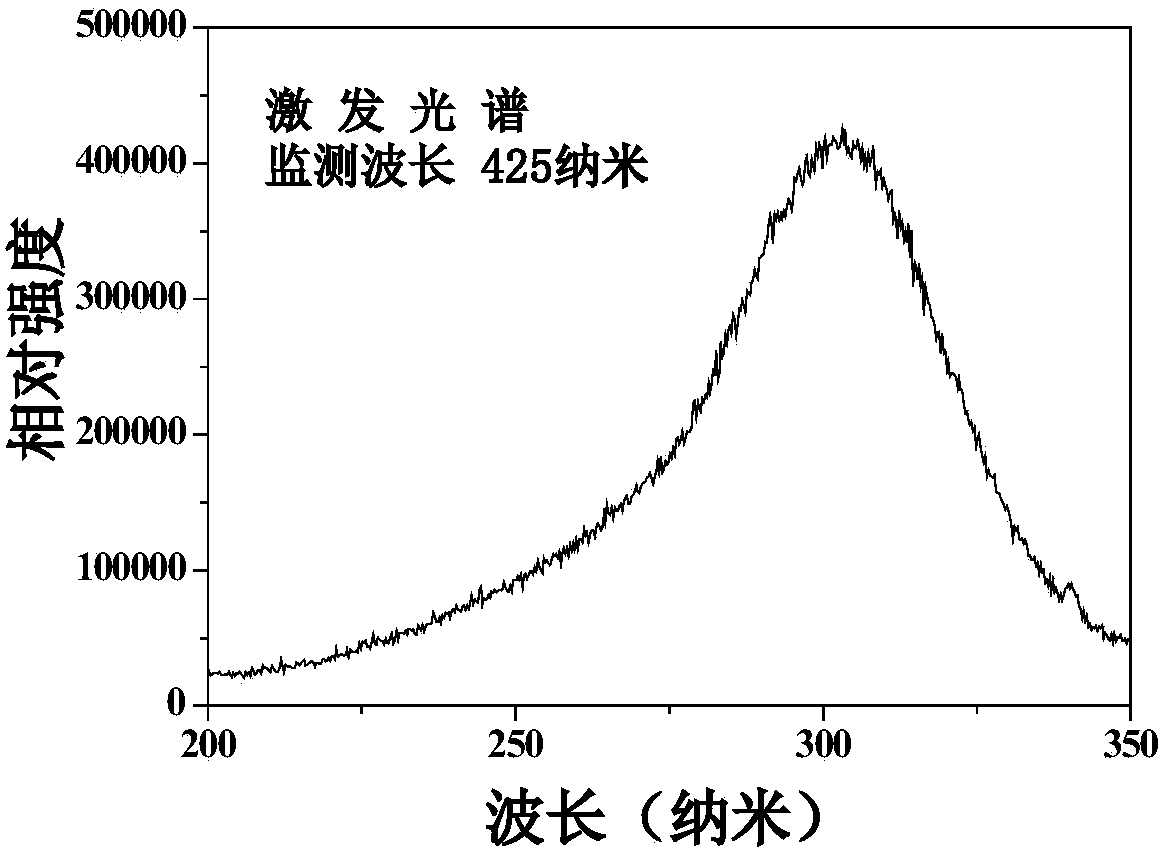

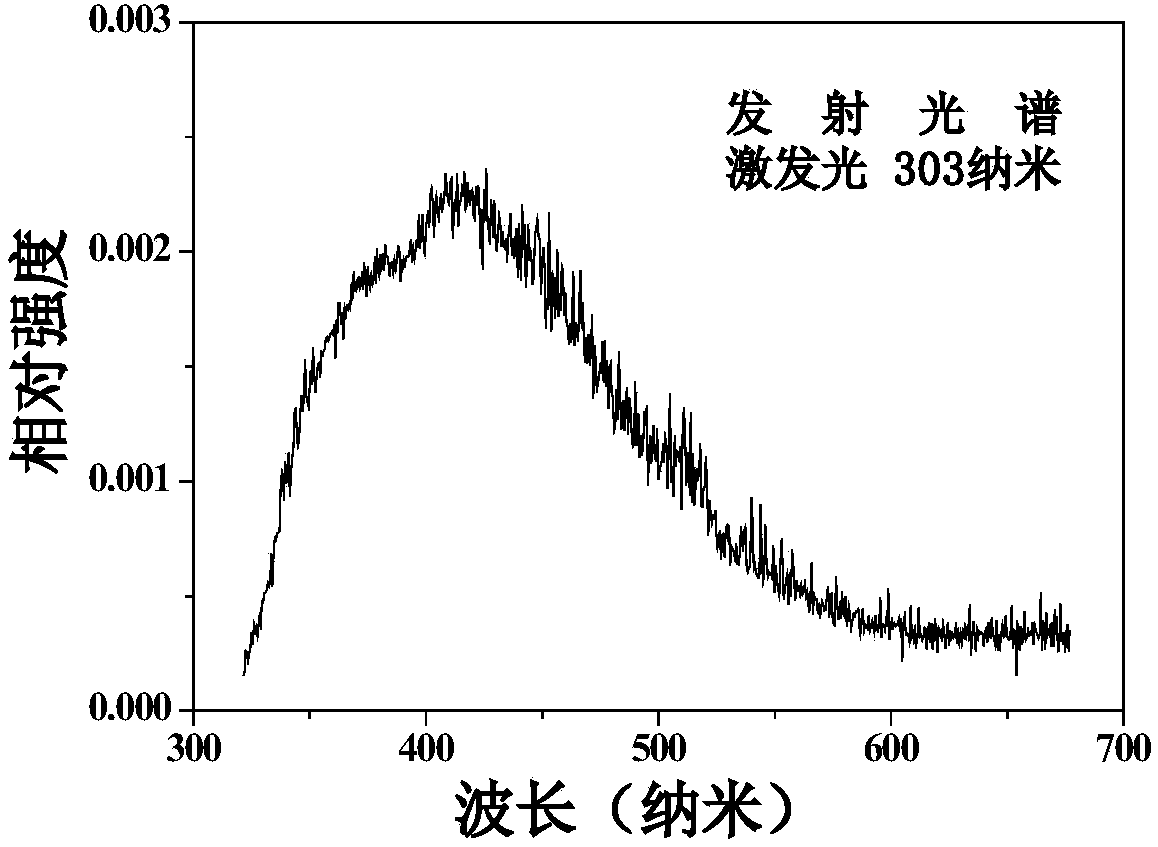

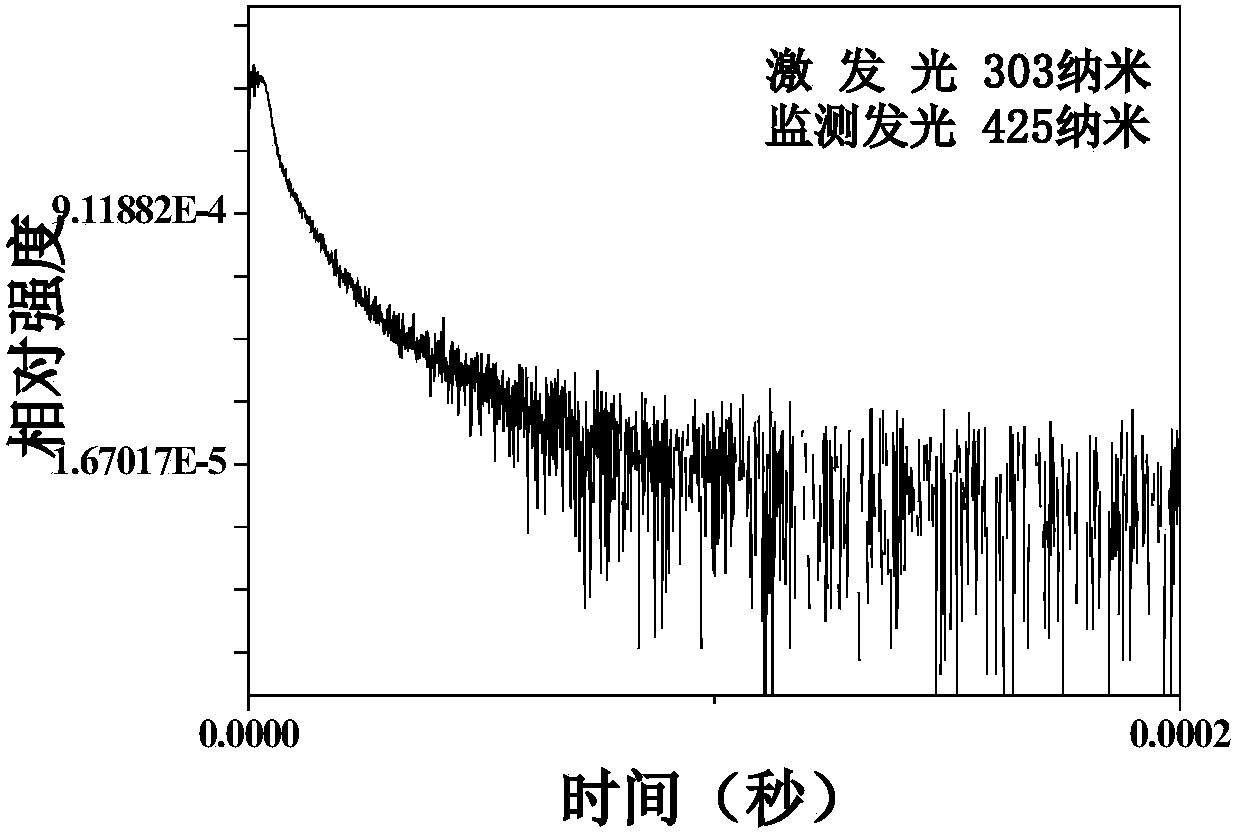

[0029] See attached figure 1...

Embodiment 2

[0034] Preparation of Sr 7 Y 5.994 Ce 0.006 OF 30

[0035] According to the chemical formula Sr 7 Y 5.994 Ce 0.006 OF 30 The stoichiometric ratio of each element in the formula is weighed as strontium carbonate SrCO 3 : 2.5835 g, yttrium fluoride YF 3 : 2.1863 grams, cerium nitrate Ce (NO 3 ) 3 ·6H 2 O: 0.0065 g, ground and mixed well in an agate mortar, buried in 5.7316 g of ammonium fluoride NH 4In F, select a reducing atmosphere for pre-calcination, the pre-calcination temperature is 400 ° C, the pre-calcination time is 15 hours, then cool to room temperature, take out the sample; the pre-calcined sample is fully mixed and ground again, and buried in 5.7316 grams of fluoride Ammonium NH 4 In F, the final calcination is carried out in a reducing atmosphere, the calcination temperature is 1400° C., the calcination time is 1 hour, and it is naturally cooled to room temperature, and the sample is taken out to obtain a powder blue phosphor.

[0036] Its main excita...

Embodiment 3

[0038] Preparation of Sr 7 Y 5.97 Ce 0.03 OF 30

[0039] According to the chemical formula Sr 7 Y 5.97 Ce 0.03 OF 30 The stoichiometric ratio of each element in the element, weigh strontium nitrate Sr(NO 3 ) 2 : 3.7035 grams, yttrium nitrate Y (NO 3 ) 3 ·6H 2 O: 5.7172 g, cerium tetrafluoride CeF 4 : 0.0119 g, after grinding and mixing well in an agate mortar, buried in 11.3191 g of ammonium fluoride NH 4 In F, select a reducing atmosphere for pre-calcination, the pre-calcination temperature is 550°C, and the pre-calcination time is 10 hours, then cool to room temperature, and take out the sample; the pre-calcined sample is fully mixed and ground again, and buried in 11.3191 grams of fluoride Ammonium NH 4 In F, the final calcination is carried out in a reducing atmosphere, the calcination temperature is 950° C., the calcination time is 12 hours, and it is naturally cooled to room temperature, and the sample is taken out to obtain a powder blue phosphor.

[0040...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com