Solid-liquid two-phase anaerobic fermentation apparatus and method

An anaerobic fermentation, one-stage technology, applied in the field of solid-liquid two-stage anaerobic fermentation devices, can solve the problems of organic matter degradation rate, low biogas conversion rate, difficult treatment, affecting biogas production efficiency, etc., to overcome the problem of unstable gas production , Improve the efficiency of anaerobic digestion, which is conducive to the effect of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The method of the present invention is described below through specific embodiments. Unless otherwise specified, the technical means used in the present invention are methods known to those skilled in the art. In addition, the embodiments are to be understood as illustrative, rather than limiting, of the scope of the invention, the spirit and scope of the invention being limited only by the claims.

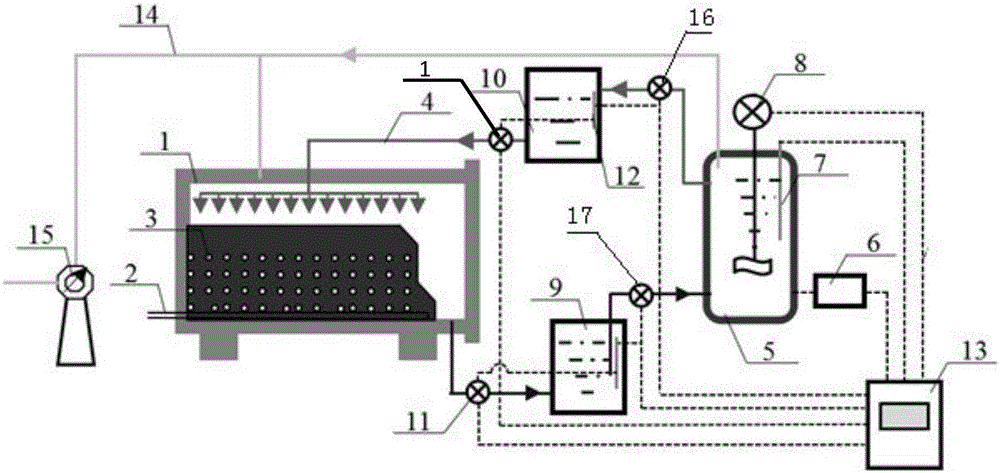

[0044] A solid-liquid two-stage anaerobic fermentation device, such as figure 1 As shown, it includes a solid acid-producing fermentation reactor 1 (4-6 sets), a liquid methane-producing reactor 5, an acid-producing fermentation liquid collection tank 9, a biogas liquid collection tank 10, a circulating heating device 6, a biogas meter 15, and a mixer 8. Sewage pumps 11, 16, 17 and 18, liquid level sensor 12, temperature sensor 7 and automatic control cabinet 13.

[0045] The solid acid-producing fermentation reactor includes a horizontal dry fermentation reaction chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com