Silicon oxide/carbon/metal element composite material and preparation method and application thereof

A technology of composite materials and elements, which is applied in the direction of electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of poor conductivity, low initial Coulombic efficiency, and poor capacity performance, and achieve simple preparation methods, high Coulombic efficiency, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

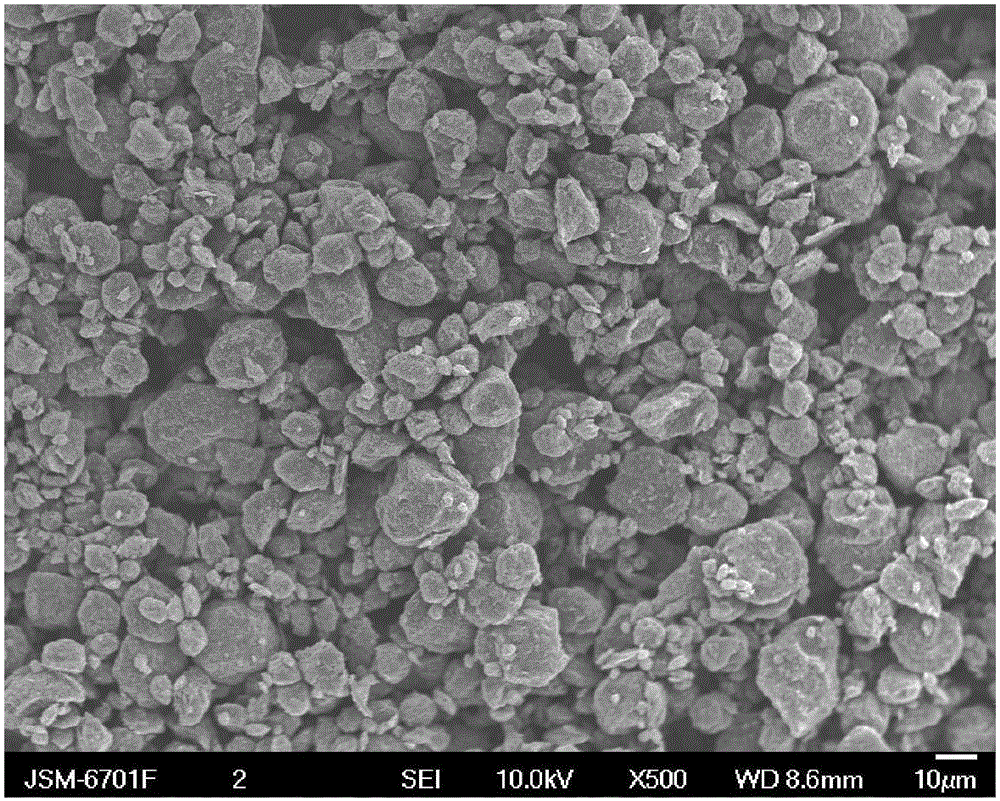

[0029] 3 kg of SiO with an average particle size of 5 μm x , 500g sucrose, 500g polyvinylpyrrolidone, 50g aluminum powder and 40L water are added in the planetary ball mill, the ball mill speed is 600r / min, after grinding for 12 hours, filter and remove the particles with a particle size greater than 1 μm in the slurry, and then The slurry is added to the sand mill grinding tank, the sand mill speed is 1200r / min, after grinding for 12 hours, then 6kg of flake graphite, 300g graphene and 300g SuperP with an average particle diameter of 5 μm are added to the above slurry , and transfer the slurry to a ball mill for ball milling for 4 hours, the speed of the ball mill is 400r / min, after the obtained slurry is dried and shaped by a spray dryer, it is sintered in a nitrogen atmosphere in a rotary kiln at a sintering temperature of 700°C, and the temperature rises The rate is 5°C / min, sintering for 2h, the obtained SiO x / C / M composite materials are screened, demagnetized and baled...

Embodiment 2

[0033] 3 kg of SiO with an average particle size of 1 μm x , 500g of sodium alginate, 500g of polyacrylic acid, 50g of magnesium powder and 40L of water were added to a planetary ball mill. and 300g of Ketjen Black were added to the above slurry, and ball milling was continued for 8 hours in a ball mill with a rotation speed of 400r / min. After the obtained slurry was dried and shaped by a spray dryer, it was sintered in an argon atmosphere in a roller kiln. treatment, the sintering temperature is 800°C, the heating rate is 10°C / min, and the sintering is 3h, the obtained SiO x / C / M composite materials are screened, demagnetized and baled.

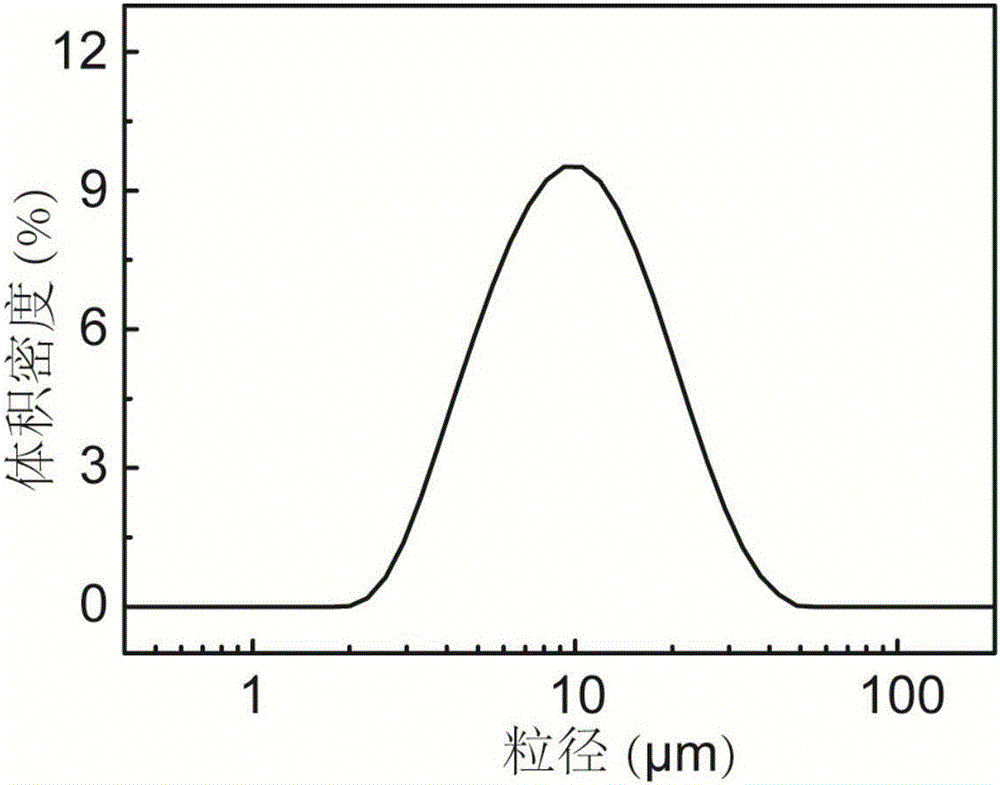

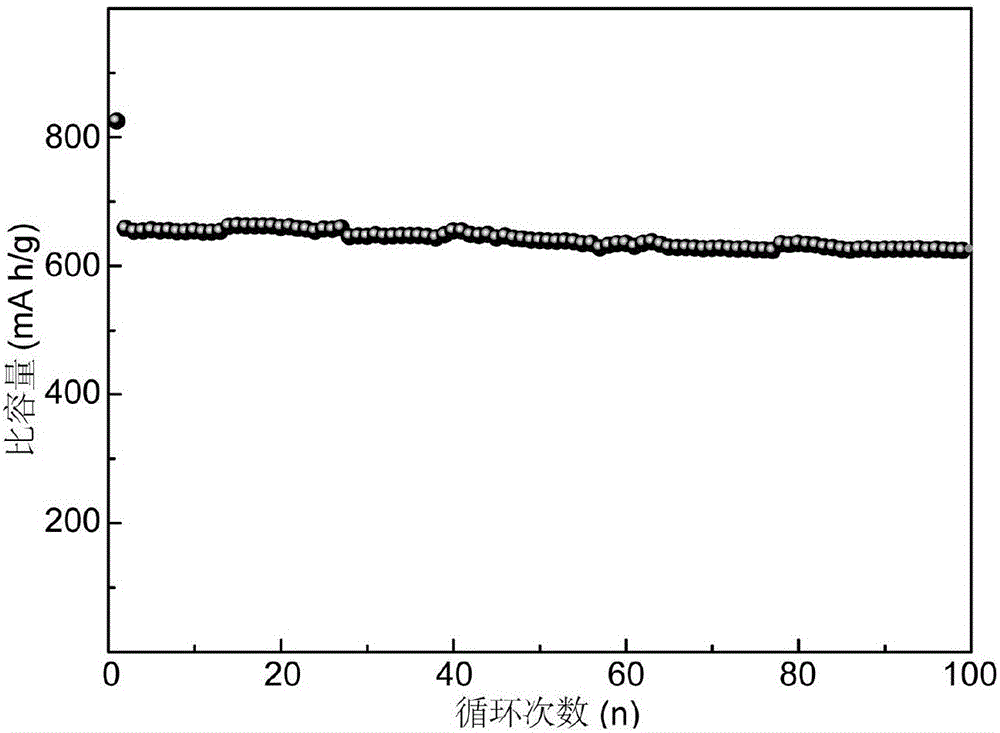

[0034] Scanning electron microscope (JEOL-6700F) test obtained SiO under the above conditions x / C / M composite morphology, its particle size distribution was tested with a laser particle size analyzer, and the test results are shown in Table 1; SiO x The value of x in the middle is 1, and the content is 30%. The carbon material exists in ...

Embodiment 3

[0037] 4 kg of SiO with an average particle size of 5 μm x , 500g of polyacrylic acid, 1000g of polyvinylpyrrolidone, 100g of zinc powder and 40L of water were added to a planetary ball mill, the speed of the ball mill was 600r / min, after grinding for 12 hours, the particles with a particle size greater than 1 μm in the slurry were removed by sieve filtration, Slurry is then joined in the sand mill grinding tank, and the sand mill speed is 1200r / min, after grinding for 12 hours, then 5kg average particle diameter is 7 μ m flake graphite, 300g graphene joins in the above-mentioned slurry, and Transfer the slurry to a ball mill and mill for 4 hours at a speed of 400r / min. After the resulting slurry is dried and shaped by a spray dryer, it is sintered in a nitrogen atmosphere in a pusher kiln. The sintering temperature is 600°C and the heating rate is 5 ℃ / min, sintering 2h, the obtained SiO x / C / M composite materials are screened, demagnetized and baled.

[0038] Scanning ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com