Preparation method and application of mixed matrix membrane containing zeolite imidazolate framework material

A technology of mixed matrix membrane and zeolite imidazole, which is applied in the field of membrane separation, can solve the problems of short life, weak gas permeability, and difficult film formation brittleness, and achieve the effect of compact structure, high separation and permeability, and no introduction of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The preparation of ZIF-7 / Matrimid mixed matrix film comprises the following steps:

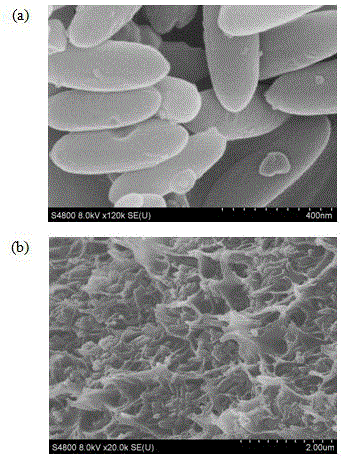

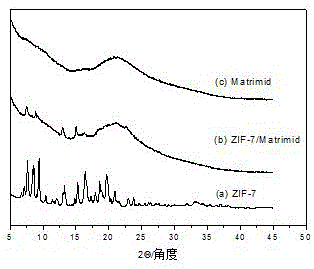

[0023] 1. Preparation of ZIF-7 nanoparticles: 0.265 g zinc chloride (ZnCl 2 ) and 0.310 g of benzimidazole were dissolved in 30 ml of N-N dimethylformamide (DMF), added with 0.465 g of diethylamine, stirred for about 30 minutes, poured into the reactor, and reacted at 130 °C for 24 hours. After the reaction, the product was collected by centrifugation, washed three times with methanol and centrifuged, and then dried overnight in an oven at 60 °C.

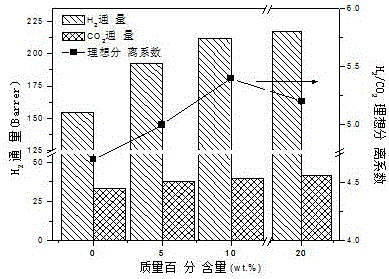

[0024] 2. Preparation of film-making solution: the film-making solution required to prepare a mixed matrix film with a mass percentage of 5 wt%. Disperse 0.02 g ZIF-7 nanoparticles in chloroform, and ultrasonically disperse the ZIF-7 particles for 30 minutes. 0.38 g of Matrimid was added in batches and stirred for 48 hours to obtain a uniform film-forming solution. Sonicate and stir before scraping the film, and let stand to prepare the s...

Embodiment 2

[0027] The preparation of ZIF-7 / Matrimid mixed matrix film comprises the following steps:

[0028] 1. Preparation of ZIF-7 nanoparticles

[0029] With above-mentioned embodiment 1.

[0030] 2. Preparation of film-making solution: the film-making solution required to prepare a mixed matrix film with a mass percentage of 10 wt%. Disperse 0.04 g of ZIF-7 nanoparticles in chloroform, and ultrasonically disperse the ZIF-7 particles for 30 minutes. 0.36 g of Matrimid was added in batches and stirred for 48 hours to obtain a uniform film-forming solution. Sonicate and stir before scraping the film, and let stand to prepare the scraping film.

[0031] 3. Film making

[0032] With above-mentioned embodiment 1.

Embodiment 3

[0034] The preparation of ZIF-7 / Matrimid mixed matrix film comprises the following steps:

[0035] 1. Preparation of ZIF-7 nanoparticles

[0036] Same as previous embodiment 1.

[0037] 2. Preparation of membrane-forming solution: the membrane-forming solution required to prepare a mixed matrix membrane with a mass percentage of 20 wt%. Disperse 0.08 g of ZIF-7 nanoparticles in chloroform, and ultrasonically disperse the ZIF-7 particles for 30 minutes. 0.32 g of Matrimid was added in batches and stirred for 48 hours to obtain a uniform film-forming solution. Sonicate and stir before scraping the film, and let stand to prepare the scraping film.

[0038] 3. Film making

[0039] Same as previous embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com