Conductive anticorrosive paint for power grounding grid and preparation method thereof

A conductive anti-corrosion and grounding grid technology, applied in anti-corrosion coatings, conductive coatings, epoxy resin coatings, etc., can solve problems such as corrosion and limit the application of coatings, and achieve the effects of improving electrical conductivity, anti-corrosion performance, and wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

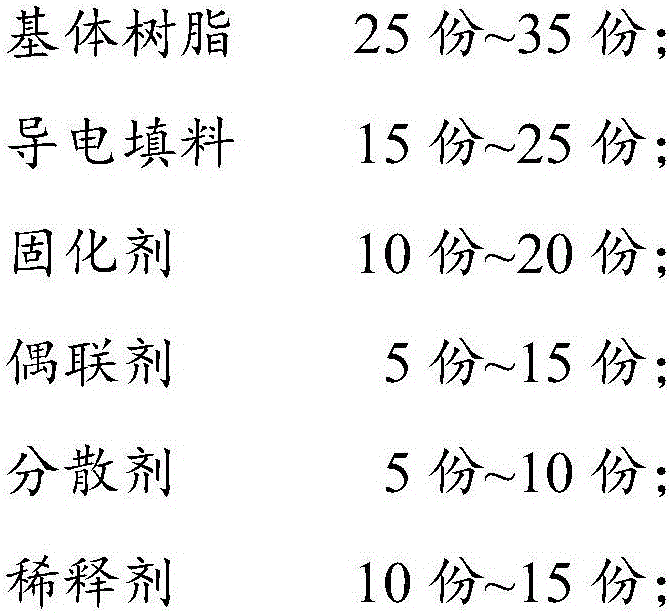

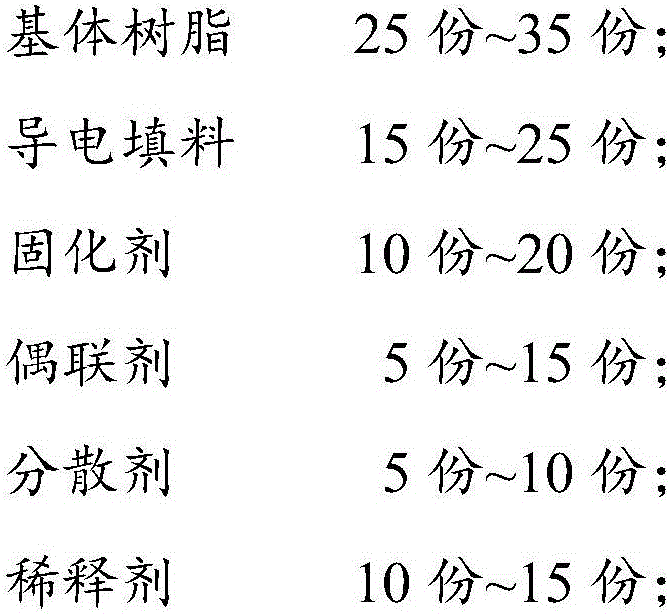

[0026] Embodiment 1. This embodiment provides a conductive anticorrosion coating for the grounding grid of a power grid, which includes the following components in parts by weight, 25 parts of matrix resin, 15 parts of conductive filler, 10 parts of a mixture of modified polyenylamine and modified phenalkamine 5 parts, 5 parts of sodium dodecylsulfonate, 5 parts of silane coupling agent (KH550), 10 parts of benzyl glycidyl ether, wherein the conductive coating includes carbon nanotubes and modified graphite in a mass ratio of 1:2:1 ene and nanoscale titanium dioxide.

[0027] First, under the protection of nitrogen, measure polyethylene glycol and epoxy resin into a reaction kettle equipped with a stirrer, a thermometer and a reflux condensing device, heat up to 70°C, start the stirrer, and stir at a speed of 400r / min After 20 hours, continue to heat up to 100°C, continue to stir and react for 4 hours to obtain a water-based epoxy resin prepolymer; then, prepare an aqueous sol...

Embodiment 2

[0028] Embodiment 2. This embodiment provides a conductive anticorrosion coating for the grounding grid of a power grid, which includes the following components in parts by weight, 35 parts of matrix resin, 25 parts of conductive filler, 15 parts of a mixture of modified polyenylamine and modified phenalkamine Parts, 10 parts of sodium dodecylsulfonate, 10 parts of silane coupling agent (KH550), 15 parts of xylene and butyl acetate (mixing mass ratio 2:3).

[0029] First, under the protection of nitrogen, measure polyethylene glycol and epoxy resin into a reaction kettle equipped with a stirrer, a thermometer and a reflux condensing device, heat up to 70°C, start the stirrer, and stir at a speed of 400r / min After 20 hours, continue to heat up to 100°C, continue to stir and react for 4 hours to obtain a water-based epoxy resin prepolymer; then, prepare an aqueous solution of sodium hydroxide, add 200-300 mesh modified graphene, stir and mix evenly, then heat up to 40°C, and then...

Embodiment 3

[0030] Embodiment 3. This embodiment provides a conductive anti-corrosion coating for the grounding grid of a power grid. According to parts by weight, it includes the following ingredients: 30 parts of matrix resin, 19 parts of conductive filler, 14 parts of a mixture of modified polyenamine and modified phenalkamine 15 parts, 8 parts of Tween, 15 parts of silane coupling agent (KH550), 15 parts of n-butanol.

[0031] First, under the protection of nitrogen, measure polyethylene glycol and epoxy resin into a reaction kettle equipped with a stirrer, a thermometer and a reflux condensing device, heat up to 70°C, start the stirrer, and stir at a speed of 400r / min After 20 hours, continue to heat up to 100°C, continue to stir and react for 4 hours to obtain a water-based epoxy resin prepolymer; then, prepare an aqueous solution of sodium hydroxide, add 200-300 mesh modified graphene, stir and mix evenly, then heat up to 40°C, and then Add carbon nanotubes and nanoscale titanium d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com