Preparation method of bio-functionalized chitosan hydrogel

A technology of dehydrating and functionalizing chitosan, which is applied in the field of tissue engineering biomaterials, can solve the problems of denaturation and inactivation of biological functional molecules, increased cytotoxicity, and harsh reaction conditions, and achieves low cost, simple method, and mild reaction conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

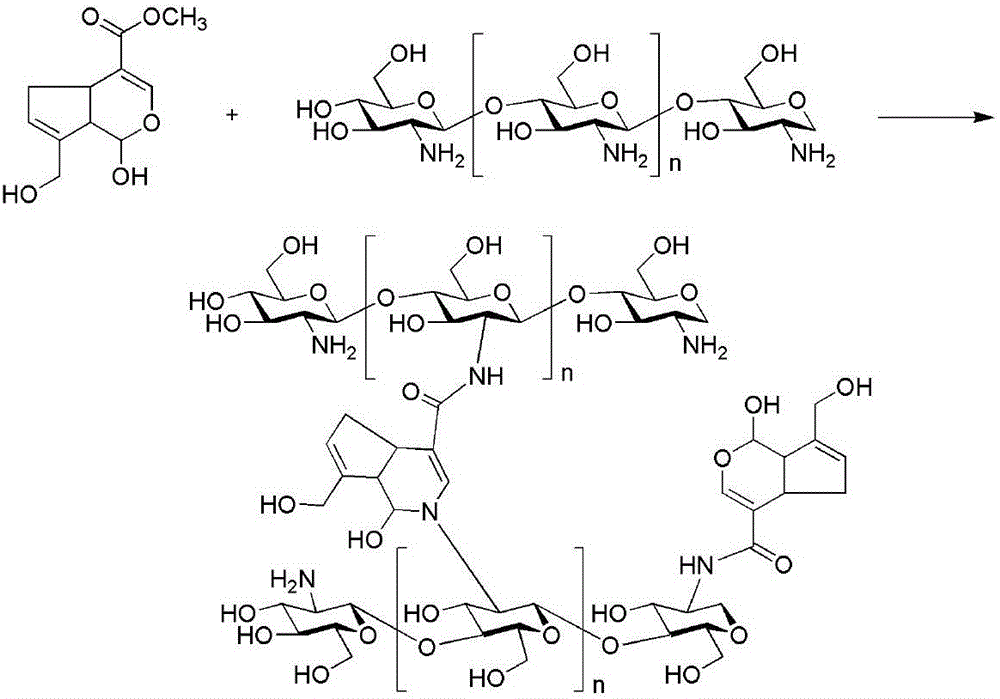

[0032] (2) preparation of chitosan solution: the chitosan of 1.5g is dissolved in the 3% acetic acid solution of 100ml and is prepared into the chitosan solution of 1.5%, and adds the biomolecule containing amino, stirs in conical flask overnight;

[0033] (3) The above two solutions are mixed according to different ratios, and the chitosan hydrogel can be obtained after standing at room temperature for 24-72 hours. Wherein, the molar ratio of genipin and amino biomolecules is kept between 10:5 and 10:1, and the molar ratio of chitosan and genipin is kept between 300:1 and 30:10.

[0034] (4) Performance determination of functionalized chitosan hydrogel:

[0035] For different functionalized chitosan hydrogels, we can verify by identifying their biological functions. The most direct verification method is to introduce fluorescent molecules into the hydrogel to detect its fluorescent performance, and if it shows obvious fluorescence, the method of the present invention is fea...

Embodiment 1

[0036] Embodiment 1: one-step method prepares the chitosan hydrogel of fluorescent functionalization

[0037] Preparation:

[0038] First, dissolve 0.02g of genipin in 1ml of 75% alcohol to prepare a 2.0% genipin solution; at the same time, dissolve 1.5g of chitosan in 100ml of 3% acetic acid solution to prepare a 1.5% genipin solution chitosan solution, and add 1 mg of FITC fluorescent molecules containing amino groups, and stir overnight in the Erlenmeyer flask to obtain a mixed solution of chitosan and FITC; mix the above two solutions 1:1 evenly, and leave it at room temperature for 48 hours. A chitosan hydrogel functionalized with fluorescent molecule FITC can be obtained.

[0039] Result analysis:

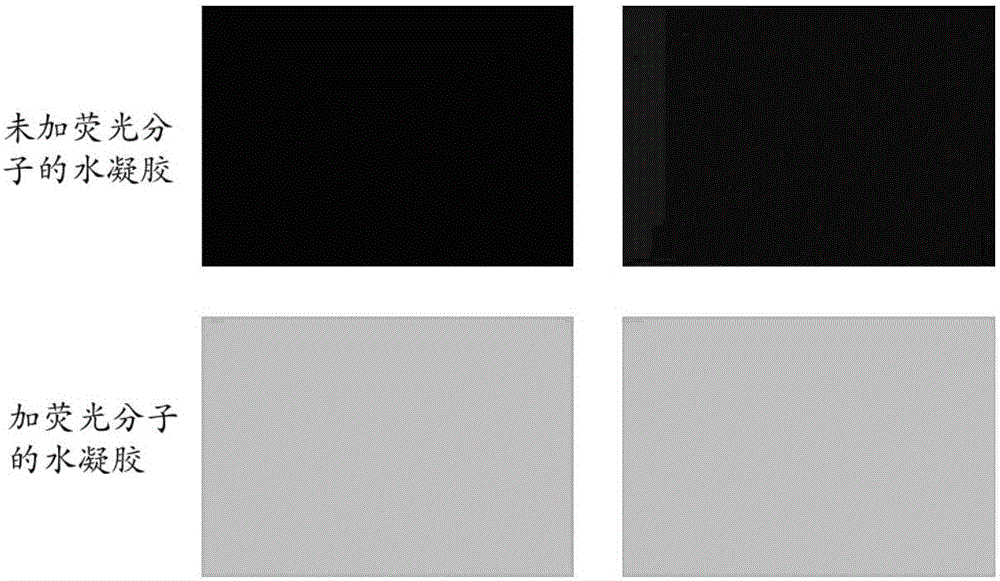

[0040] image 3 It shows that the chitosan hydrogel added with fluorescent molecules shows obvious fluorescence under the fluorescence microscope, while the chitosan hydrogel without fluorescent molecules does not show fluorescence. The results fully illustrate that the pr...

Embodiment 2

[0041] Example 2: One-step preparation of chitosan hydrogel functionalized with cell adhesion peptide RGD

[0042] Preparation:

[0043] First, dissolve 0.01g of genipin in 1ml of 75% alcohol to prepare a 1.0% genipin solution; at the same time, dissolve 1.5g of chitosan in 100ml of 3% acetic acid solution to prepare a 1.5% genipin solution. Chitosan solution, and add 1 mg of amino group-containing cell adhesion peptide GGRGDS, stir overnight in a conical flask to obtain a mixed solution of chitosan and GGRGDS; mix the above two solutions 1:1 evenly, and let stand at room temperature for 72h After that, the chitosan hydrogel with cell adhesion molecule GGRGDS can be obtained.

[0044] Result analysis:

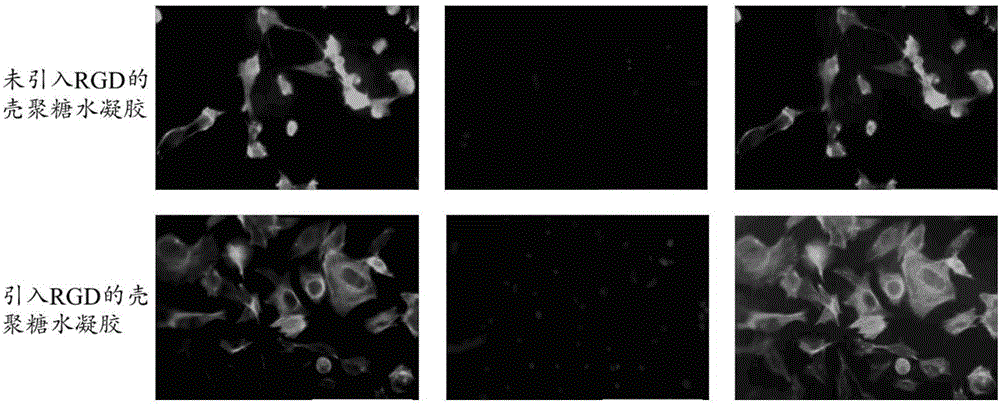

[0045] : Figure 4 MC-3T3 cells were planted for chitosan hydrogel, and after 24 hours of culture, the attached morphology of the surface cells. Cells and nuclei were stained prior to observation. The chitosan hydrogel added with GGRGD showed stronger adhesion to cells, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com