Biomass-resource-modified water-based polyurethane emulsion and preparation method thereof

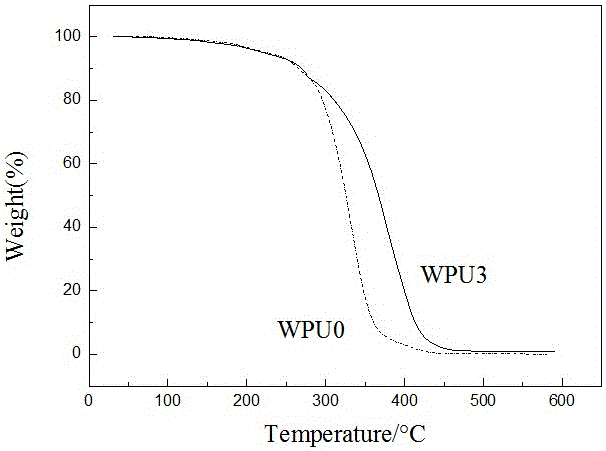

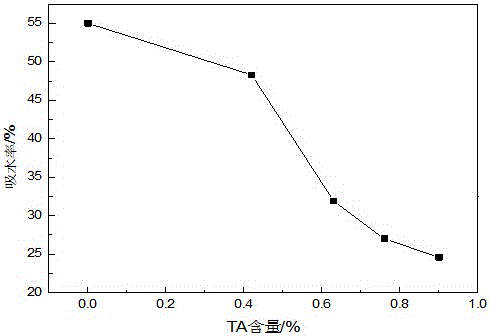

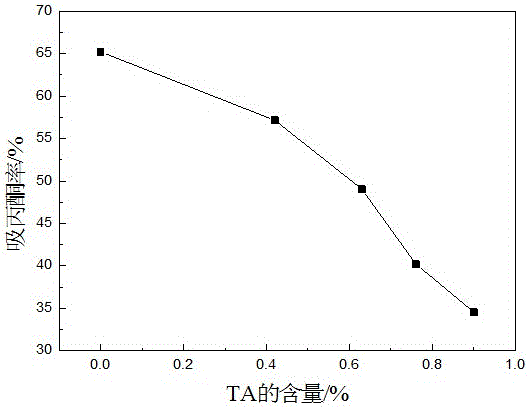

A technology of water-based polyurethane and biomass resources, applied in the field of polymer chemistry, can solve the problems of poor solvent resistance and mechanical properties, achieve the effects of low price, wide application space, and improved comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1, a kind of biomass resource modified aqueous polyurethane emulsion, is made by following method:

[0024] 1) Firstly, polycaprolactone, isophorone diisocyanate and dimethylolbutyric acid are added to a dry reactor to carry out polymerization isophorone reaction at 70°C, in which isophorone diisocyanate and polycaprolactone The mass ratio of ester is 0.74:1, the mass ratio of isophorone diisocyanate to dimethylol butyric acid is 5.67:1; the reaction time is 4h;

[0025] 2) Add chain extender 1,4-butanediol to the reactor at 65°C for 3 hours, wherein the mass ratio of 1,4-butanediol to polycaprolactone is 0.051:1;

[0026] 3) Cool down to 20°C, add triethylamine to adjust the pH value of the reaction system to 7, and the reaction time is 2.5h;

[0027] 4) Under high-speed stirring, add an aqueous solution of tannic acid with a mass concentration of 0.89% into the reactor and react at 45°C for 2.5 hours. The mass ratio of isophorone diisocyanate to tannic aci...

Embodiment 2

[0028] Embodiment 2, a kind of biomass resource modified aqueous polyurethane emulsion, is made by following method:

[0029] 1) First, add polytetrahydrofuran ether diol, hexamethylene diisocyanate, and dimethylol propionic acid into a dry reactor for polymerization at 75°C, in which hexamethylene diisocyanate and polytetrahydrofuran ether binary The mass ratio of alcohol is 0.67:1, the mass ratio of hexamethylene diisocyanate to dimethylol propionic acid is 5.27:1; the reaction time is 3h;

[0030] 2) Add chain extender 1,4-butanediol to the reactor at 70°C for 2 hours, wherein the mass ratio of 1,4-butanediol to polytetrahydrofuran ether diol is 0.027:1;

[0031] 3) Cool down to 25°C, add trimethylamine to adjust the pH value of the reaction system to 7.5, and the reaction time is 2h;

[0032] 4) Under high-speed stirring, add an aqueous solution of tannic acid with a mass concentration of 0.6% into the reactor and react at 30°C for 5 hours. The mass ratio of hexamethylene...

Embodiment 3

[0033] Embodiment 3, a kind of biomass resource modified aqueous polyurethane emulsion, is made by following method:

[0034] 1) First, polyoxypropylene diol, toluene diisocyanate, and sodium 1,2-dihydroxy-3-propanesulfonate are added to a dry reactor for polymerization at 80°C, in which toluene diisocyanate and polyoxypropylene diol The mass ratio of toluene diisocyanate to 1,2-dihydroxy-3-propanesulfonate is 2.9:1; the reaction time is 2h;

[0035] 2) Add chain extender 1,4-butanediol to the reactor at 60°C for 4 hours, wherein the mass ratio of 1,4-butanediol to polyoxypropylene glycol is 0.063:1;

[0036] 3) Cool down to 15°C, add triethanolamine to adjust the pH of the reaction system to 7.5, and the reaction time is 3 hours;

[0037] 4) Under high-speed stirring, add an aqueous solution of tannic acid with a mass concentration of 0.36% into the reactor and react at 40°C for 3 hours. The mass ratio of toluene diisocyanate to tannic acid is 11.77:1, and a product is obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com