Water conservancy and hydropower construction water drainage pipe

A technology for water conservancy and hydropower and drainage pipes, which is applied in the field of water conservancy and hydropower construction drainage pipes, can solve problems such as performance limitations, inability to meet use requirements, etc., achieves good elastic modulus performance indicators, improves anti-aging performance and service performance, and has good use effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

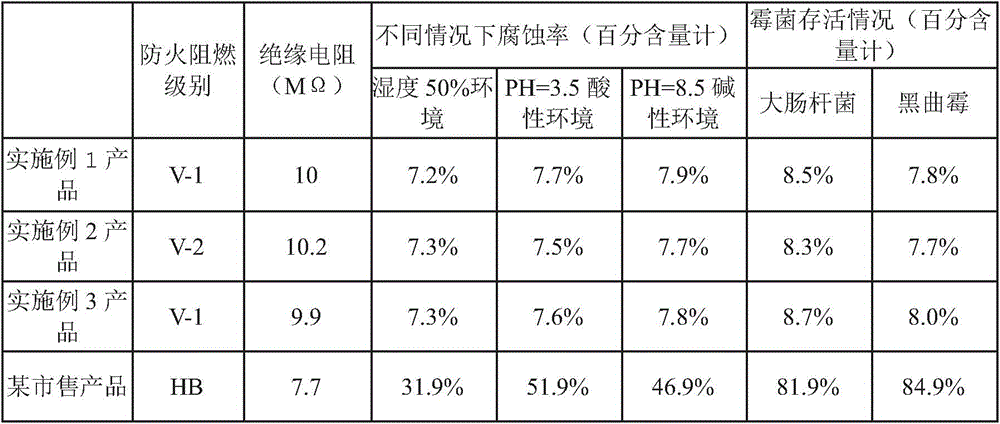

Examples

Embodiment 1

[0017] The drainage pipe for water conservancy and hydropower construction in this embodiment is composed of the following components in parts by mass: 22 parts of heat vulcanized silicone rubber, 20 parts of bisphenol A polycarbonate, 20 parts of bismaleimide resin, methyl acetate 18 parts, 20 parts of soybean oil, 20 parts of spindle oil, 18 parts of dipropylene glycol methyl ether, 20 parts of imidazoline, 20 parts of silver-loaded nano-zirconium phosphate antibacterial agent, 18 parts of ethyl paraben sodium salt, 18 parts of penicillin, ten parts 18 parts of dialkylethoxy sulfobetaine, 20 parts of quicklime powder, 18 parts of asbestos fiber, 16 parts of disodium octaborate tetrahydrate, 20 parts of silicon carbide fiber, 18 parts of manganese carbonate powder, 16 parts of iron oxide red, 18 parts of fluorescent powder, 16 parts of pearl powder, 16 parts of amidinourea phosphate, 18 parts of triethylene glycol diisocaprylate, 18 parts of p-cresol, 18 parts of polyacrylonit...

Embodiment 2

[0024]The drainage pipe for water conservancy and hydropower construction in this embodiment consists of the following components in parts by mass: 24 parts of heat vulcanized silicone rubber, 22 parts of bisphenol A polycarbonate, 22 parts of bismaleimide resin, methyl acetate 20 parts, 22 parts of soybean oil, 22 parts of spindle oil, 20 parts of dipropylene glycol methyl ether, 22 parts of imidazoline, 22 parts of silver-loaded nano-zirconium phosphate antibacterial agent, 20 parts of ethyl paraben sodium salt, 20 parts of penicillin, ten parts 20 parts of dialkylethoxy sulfobetaine, 22 parts of quicklime powder, 20 parts of asbestos fiber, 18 parts of disodium octaborate tetrahydrate, 22 parts of silicon carbide fiber, 20 parts of manganese carbonate powder, 18 parts of iron oxide red, 20 parts of fluorescent powder, 18 parts of pearl powder, 18 parts of amidinourea phosphate, 20 parts of triethylene glycol diisocaprylate, 20 parts of p-cresol, 20 parts of polyacrylonitrile...

Embodiment 3

[0031] The drainage pipe for water conservancy and hydropower construction in this embodiment consists of the following components in parts by mass: 26 parts of heat vulcanized silicone rubber, 24 parts of bisphenol A polycarbonate, 24 parts of bismaleimide resin, methyl acetate 22 parts, 24 parts of soybean oil, 24 parts of spindle oil, 22 parts of dipropylene glycol methyl ether, 24 parts of imidazoline, 24 parts of silver-loaded nano-zirconium phosphate antibacterial agent, 22 parts of ethyl paraben sodium salt, 22 parts of penicillin, ten parts 22 parts of dialkylethoxy sulfobetaine, 24 parts of quicklime powder, 22 parts of asbestos fiber, 20 parts of disodium octaborate tetrahydrate, 24 parts of silicon carbide fiber, 22 parts of manganese carbonate powder, 20 parts of iron oxide red, 22 parts of fluorescent powder, 20 parts of pearl powder, 20 parts of amidinourea phosphate, 22 parts of triethylene glycol diisocaprylate, 22 parts of p-cresol, 22 parts of polyacrylonitril...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com