Preparation method and application of nickel phosphide nano film

A technology of nano-film and nickel phosphide, applied in the field of nano-materials, can solve the problems of inflammability and explosion, and achieve the effects of good durability, economical and effective preparation method, simple and rapid preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

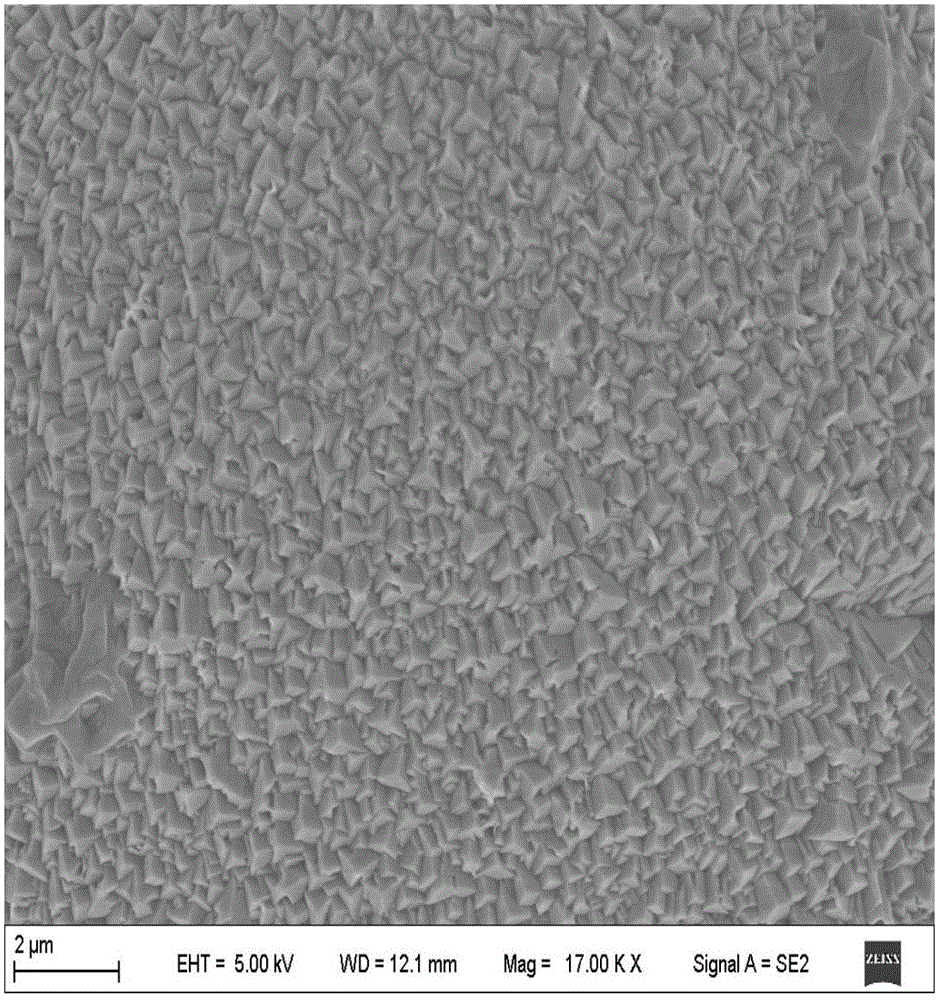

[0052] The preparation method of nickel phosphide nano film of the present invention is:

[0053] 1) Cut the commercial nickel foam into 2×4cm size, first ultrasonically in 2~4mol / l dilute hydrochloric acid for 15~25min to remove surface oxides and some sundries, then in acetone and ultrapure water respectively Each ultrasonic wave was carried out for 15-25 minutes. This process was carried out at room temperature, and then rinsed with a large amount of water to remove impurities such as surface oxides and organic matter. Finally, it was placed in a vacuum oven and dried at 35-45°C for use;

[0054] 2) Anodic oxidation: use the nickel foam washed in step 1) as an anode, and use a DC stable power supply to perform anodic oxidation in an oxalic acid solution of 0.15-0.35mol / L. The set voltage is 25-30V, and the temperature is - 5~0℃, the time is 5~10min. After the reaction, the obtained sample is washed with a large amount of water and absolute ethanol, and then dried in a vacuu...

Embodiment 1

[0057] The preparation method of nickel phosphide nano film of the present invention is:

[0058] 1) Cut the commercial nickel foam into a size of 2×4cm, first ultrasonically in 3mol / l dilute hydrochloric acid for 15min to remove surface oxides and some impurities, then ultrasonically in acetone and ultrapure water for 15min respectively, This process is carried out at room temperature, and then rinsed with a large amount of water to remove impurities such as surface oxides and organic matter, and finally placed in a vacuum oven and dried at 40°C for use;

[0059] 2) Anodizing: use the nickel foam washed in step 1) as an anode, and use a DC stabilized power supply to perform anodic oxidation in a 0.25mol / L oxalic acid solution. The set voltage is 25V, the temperature is -5°C, and the time is After the reaction, the obtained sample was washed with a large amount of water and absolute ethanol, and then dried in a vacuum oven at 60°C to obtain nickel oxalate@foam nickel;

[0060...

Embodiment 2

[0074] The preparation method of nickel phosphide nano film of the present invention is:

[0075] 1) Cut the commercial nickel foam into a size of 2×4cm, first ultrasonically in 2mol / l dilute hydrochloric acid for 25min to remove surface oxides and some impurities, then ultrasonically in acetone and ultrapure water for 20min respectively, This process is carried out at room temperature, and then rinsed with a large amount of water to remove impurities such as surface oxides and organic matter, and finally placed in a vacuum oven and dried at 40°C for use;

[0076] 2) Anodic oxidation: use the nickel foam washed in step 1) as an anode, and use a DC stable power supply to perform anodic oxidation in a 0.15mol / L oxalic acid solution. The set voltage is 30V, the temperature is -2°C, and the time is After the reaction, the obtained sample was washed with a large amount of water and absolute ethanol, and then dried in a vacuum oven at 65°C to obtain nickel oxalate@foam nickel;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com