Temperature-responsive oil-water separation filter paper and preparation method thereof

A temperature-responsive, oil-water separation technology, applied in separation methods, filter paper, filtration separation, etc., to achieve the effects of good stability, easy experimental conditions, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

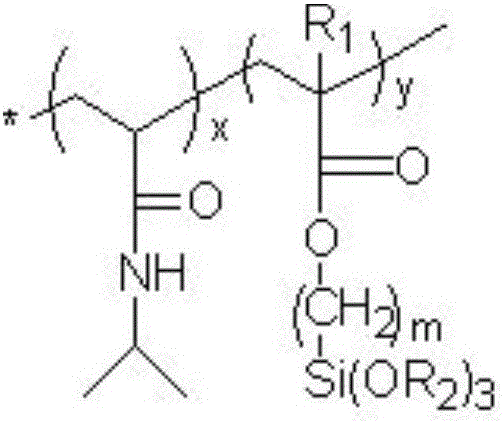

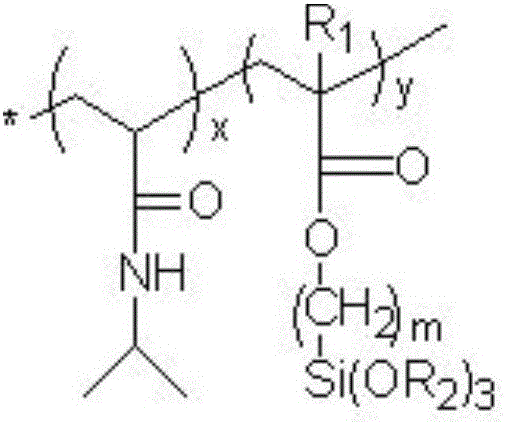

[0028] (1) Preparation of temperature-responsive polymer PNIPAM-co-PTMOSPMA

[0029] In molar ratio, N-isopropylacrylamide (NIPAM), trimethoxysilylpropyl methacrylate (TMOSPMA), and initiator azobisisobutyronitrile (AIBN) are mixed in a molar ratio of 200:100:1 Mixed and dissolved in a certain volume of anisole, and the reaction container was subjected to liquid nitrogen freezing-vacuumizing-nitrogen filling treatment, and the cycle was repeated three times. Under nitrogen protection, the reaction vessel was placed in a constant temperature oil bath at 80° C., and reacted for 10 h under electromagnetic stirring. After the system was cooled, an appropriate amount of tetrahydrofuran was added to dilute the product and precipitated in petroleum ether. After dissolution-precipitation again, vacuum-dry at room temperature for 24 h to obtain temperature-responsive polymer P1.

[0030] (2) In terms of weight ratio, mix 0.5g of nano-silica particles, 1.0g of temperature-responsive p...

Embodiment 2

[0034] (1) Preparation of temperature-responsive polymer PNIPAM-co-PTMOSPMA

[0035] The preparation method is the same as in Example 1.

[0036] (2) In terms of weight ratio, mix 0.5g of nano-silica particles, 1.5g of temperature-responsive polymer P1, 0.5g of triethylamine, and 10mL of tetrahydrofuran, and sonicate for 75 minutes until uniformly dispersed;

[0037] (3) The medium-speed qualitative filter paper (average pore size 30-50nm) was completely immersed in the mixed solution, dispersed by ultrasonic for 7 minutes, then taken out to dry naturally for 30 hours, and then vacuum-dried at room temperature for 18 hours.

[0038] (4) Use a common filter device for oil-water separation, and fold the temperature-responsive oil-water separation filter paper into a funnel shape and put it into the filter funnel. Mix petroleum ether (boiling point 60-90°C) and deionized water at a ratio of 1:1 by volume, ultrasonically disperse it into an oil-water mixture, cool to 10°C), quick...

Embodiment 3

[0040] (1) Preparation of temperature-responsive polymer PNIPAM-co-PTMOSPMA

[0041] The preparation method is the same as in Example 1.

[0042] (2) In terms of weight ratio, mix 0.5g of nano-silica particles, 2.0g of temperature-responsive polymer P1, 0.5g of triethylamine, 10mL of N, N-dimethylformamide, and sonicate for 90 minutes until uniformly dispersed;

[0043] (3) Completely immerse medium-speed qualitative filter paper (average pore size 30-50nm) in the mixture, ultrasonically disperse it for 10 minutes, take it out and dry it naturally for 24 hours, and then vacuum-dry it at room temperature for 12 hours.

[0044] (4) Use a common filter device for oil-water separation, and fold the temperature-responsive oil-water separation filter paper into a funnel shape and put it into the filter funnel. Mix petroleum ether (boiling point 60-90°C) and deionized water at a volume ratio of 1:1, ultrasonically disperse it into an oil-water mixture in a constant temperature water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com