Method for preparing barium-based glass frit by using barium slag

A technology of glass frit and barium slag, which is applied in the field of industrial waste slag treatment and comprehensive utilization, can solve problems such as high aluminum can not be used, and achieve the effects of less air bubbles, ecological environment protection, low resource consumption and environmental costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

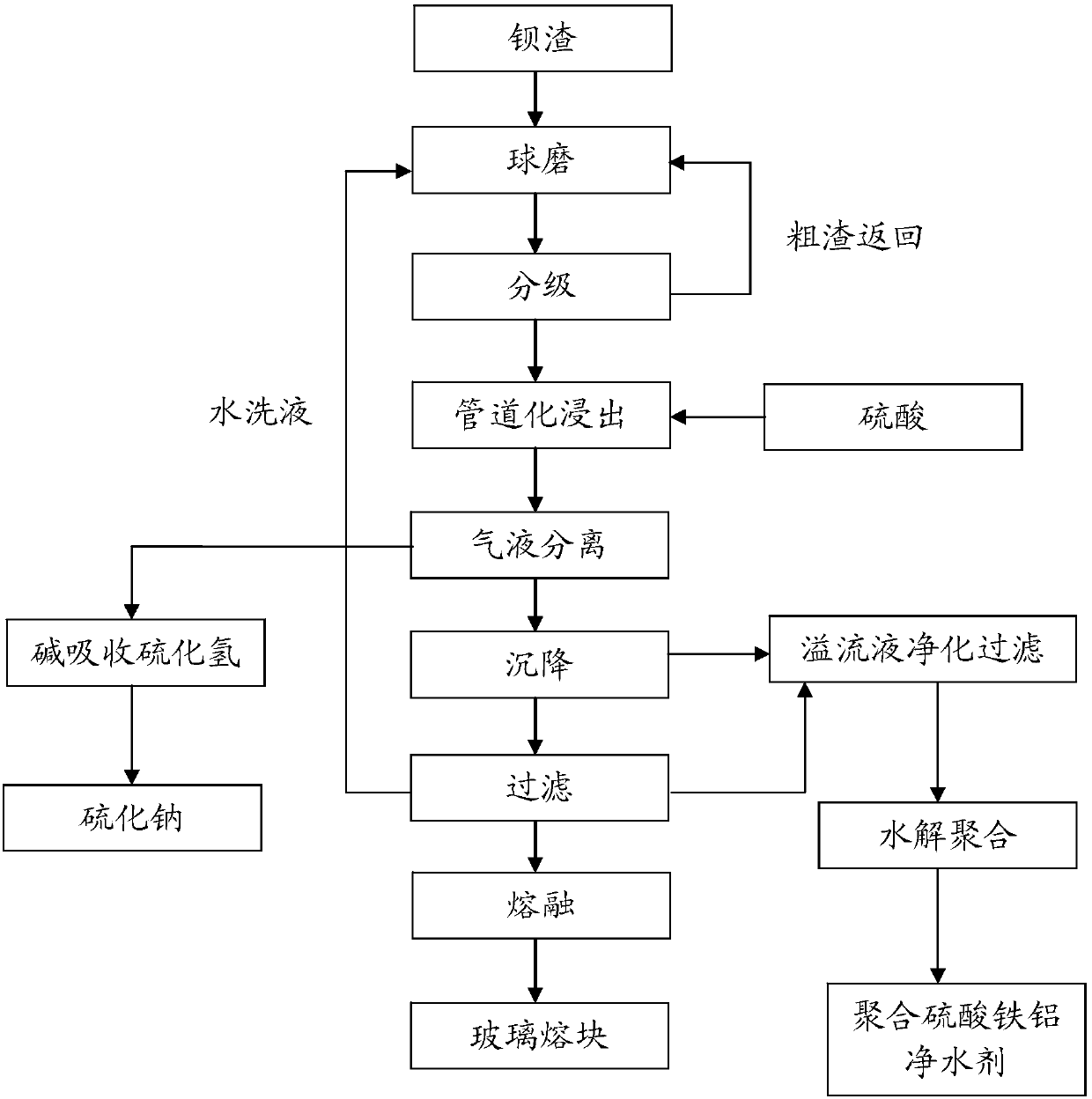

Image

Examples

Embodiment 1

[0061] (1) Use a ball mill to grind the barium slag to 100 mesh, and adjust the barium slag slurry with water, wherein the mass ratio of solid to liquid in the slurry is 1:2.5.

[0062] (2) The slurry pump feeds the barium slag slurry into the leaching pipeline, and at the same time, the sulfuric acid pump pumps 105% sulfuric acid into the pipeline, with an initial pressure of 16kg / cm 2 , terminal pressure 0.5kg / cm 2 , the pH value of the reaction liquid is controlled to be 1, and the reaction time is 5 minutes. After the reaction, the material enters the gas-liquid separation buffer tank for gas-liquid separation.

[0063] (3) The separated gas enters the absorption tower and is absorbed by sodium hydroxide to prepare sodium sulfide. The mud enters the settling tank, and the overflow liquid from the upper part of the settling tank is filtered and purified, and then enters the hydrolysis reaction tank to prepare polyferric aluminum sulfate water purifying agent.

[0064] (4...

Embodiment 2

[0067] (1) Use a ball mill to grind the barium slag to 200 mesh, and adjust the barium slag slurry with water, wherein the mass ratio of solid to liquid in the slurry is 1:1.25.

[0068] (2) The slurry pump feeds the barium slag slurry into the leaching pipeline, and at the same time, the sulfuric acid pump pumps 98% sulfuric acid into the pipeline, with an initial pressure of 10kg / cm 2 , terminal pressure 8kg / cm 2 , the pH value of the reaction liquid is controlled to be 2, and the reaction time is 10 minutes. After the reaction, the material enters the gas-liquid separation buffer tank for gas-liquid separation.

[0069] (3) The separated gas enters the absorption tower and is absorbed by sodium hydroxide to prepare sodium sulfide. The mud enters the settling tank, and the overflow liquid from the upper part of the settling tank is filtered and purified, and then enters the hydrolysis reaction tank to prepare polyferric aluminum sulfate water purifying agent.

[0070] (4)...

Embodiment 3

[0073] (1) Use a ball mill to grind the barium slag to 300 mesh, and adjust the barium slag slurry with water, wherein the mass ratio of solid to liquid in the slurry is 1:1.25.

[0074] (2) The slurry pump feeds the barium slag slurry into the leaching pipeline, and at the same time, the sulfuric acid pump pumps 93% sulfuric acid into the pipeline with an initial pressure of 10kg / cm 2 , terminal pressure 2kg / cm 2 , the pH value of the reaction liquid was controlled to be 3, and the reaction time was 20 minutes. After the reaction, the material enters the gas-liquid separation buffer tank for gas-liquid separation.

[0075] (3) The separated gas enters the absorption tower and is absorbed by sodium hydroxide to prepare sodium sulfide. The mud enters the settling tank, and the overflow liquid from the upper part of the settling tank is filtered and purified, and then enters the hydrolysis reaction tank to prepare polyferric aluminum sulfate water purifying agent.

[0076] (4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com