Reparative coating and application thereof in repairing coating of silicon carbide-based composite material

A composite material and silicon carbide-based technology, which is applied in the field of repairing anti-oxidation coatings on the surface of silicon carbide-based composite materials, can solve problems such as poor chemical compatibility, low service temperature, and reduced coating reliability, and achieve high-temperature viscosity improvement. junction performance, improved reliability, and performance-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Weigh 15wt% polyborosilazane, 25wt% SiC powder, 25wt% ZrB 2 powder, 35wt% petroleum ether, wherein SiC powder particle size is 500nm, ZrB 2The particle size of the powder is 200nm. The above materials were placed in a ceramic ball mill jar and ball milled for 30 minutes to form a coating slurry. Grind the damaged part of the C / SiC composite coating, and form a buffer zone with a width of 5mm, wash and dry. Use a brush to brush the coating slurry on the surface of the composite material, wait for it to dry after each layer of brushing, and brush until it is flush with the surrounding coating. Adjust the temperature of the heat gun to 240°C and blow for 90 minutes to cure the coating. At this time, the damaged part of the C / SiC composite coating has been repaired.

Embodiment 2

[0048] Weigh 20wt% polysilazane, 20wt% SiC powder, 25wt% ZrB 2 powder, 5wt% B powder, 30wt% tetrahydrofuran, wherein SiC powder particle size is 500nm, ZrB 2 The particle size of the powder is 200nm, and the particle size of B powder is 500nm. The above materials were placed in a ceramic ball mill jar and ball milled for 10 minutes to form a coating slurry. The C / C-SiC composite was polished, washed with absolute ethanol, and dried. Use a brush to brush the coating slurry on the surface of the composite material to form an overall coating, wait for it to dry after each layer of brushing, and brush 8 times in total. Adjust the temperature of the heat gun to 300°C and blow for 60 minutes to cure the coating. At this time, the damaged part of the C / C-SiC composite coating has been repaired.

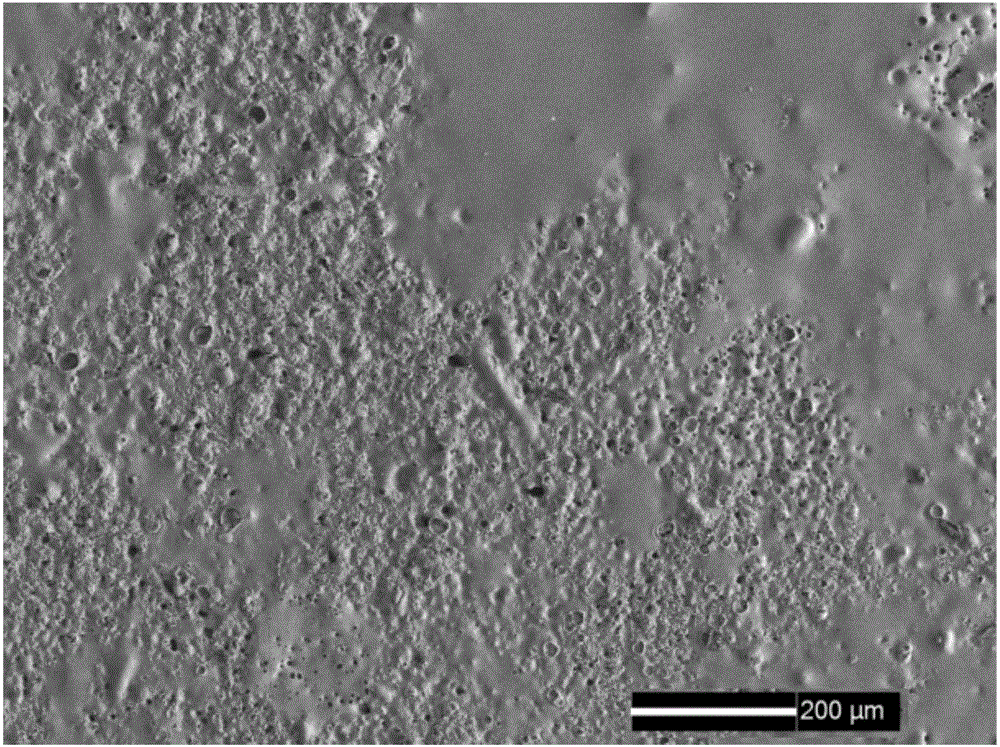

[0049] The surface micro-morphology of the obtained repaired coating is shown in Fig. figure 1 shown by figure 1 It can be seen that the surface of the repaired coating is smooth withou...

Embodiment 3

[0051] (1) Weigh 30wt% polycarbosilane-divinylbenzene solution, 35wt% SiC powder, and 35wt% tetrahydrofuran, wherein the particle size of SiC powder is 500nm. The above materials were placed in a ceramic ball mill jar and ball milled for 10 minutes to form a coating slurry. Grind the damaged part of the C / SiC composite coating, and form a buffer zone with a width of 5mm, wash and dry. Use a brush to apply the coating slurry to the damaged surface of the composite material and the buffer zone, wait for it to dry after each layer of brushing, and brush twice. Adjust the temperature of the heat gun to 180°C and blow for 30 minutes to cure the coating, and obtain a C / SiC composite material with a PCS-DVB-SiC coating on the damaged part.

[0052] (2) Weigh respectively 20wt% liquid polycarbosilane, 25wt% SiC powder, 15wt% ZrB 2 powder, 5wt% B powder and 35wt% n-hexane, wherein the particle size of SiC powder is 500nm, ZrB 2 The particle size of the powder is 200nm, and the parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com