Biological membrane and preparation method thereof

A biomembrane and membrane tissue technology, applied in tissue regeneration, medical science, prosthesis, etc., can solve the problem of high toxicity of polyethylene glycol octylphenyl ether, poor biocompatibility and safety, damage to collagen fiber structure, etc. problem, to achieve good decellularization and degreasing effect, improve decellularization efficiency, and less damage to collagen fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

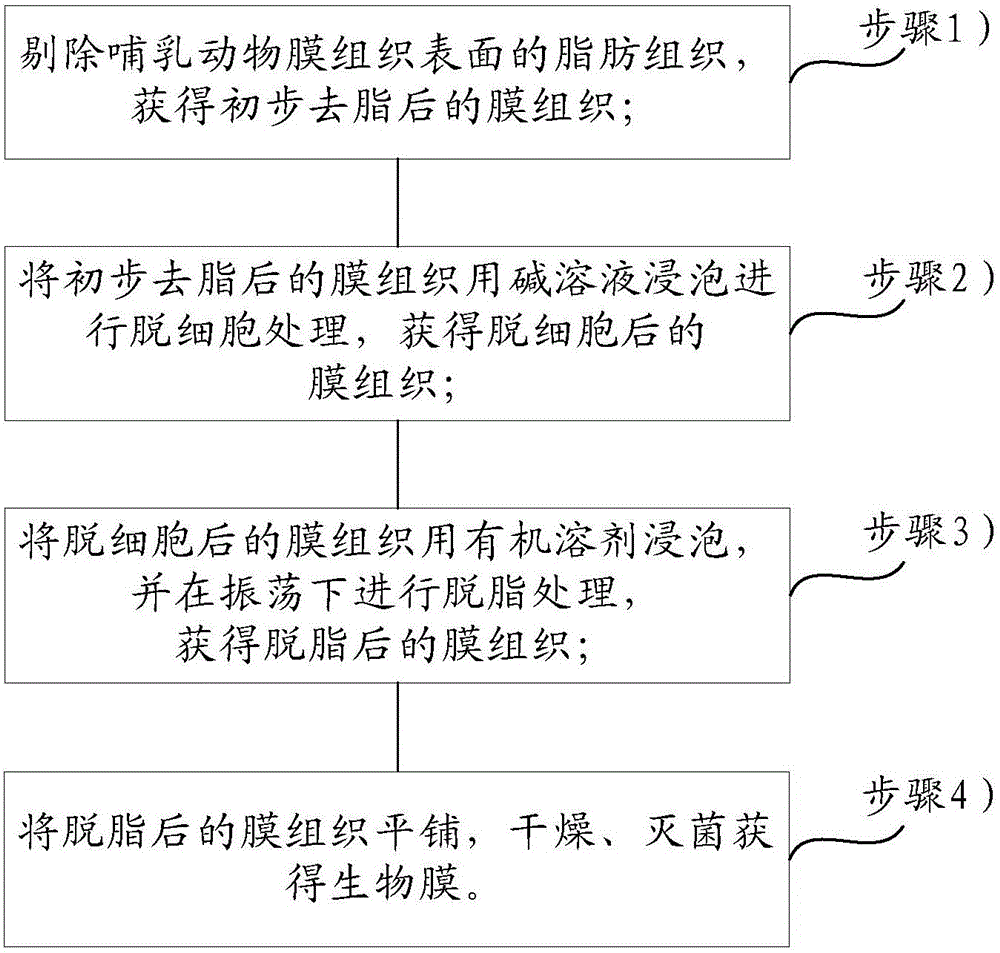

[0025] On the one hand, the embodiment of the present invention provides a kind of preparation method of biofilm, see figure 1 ,include:

[0026] Step 1) remove the fatty tissue on the surface of the mammalian membrane tissue, and obtain the membrane tissue after the preliminary fat removal;

[0027] Step 2) Soaking the membrane tissue after preliminary degreasing with alkaline solution for decellularization treatment to obtain the membrane tissue after decellularization;

[0028] Step 3) Soak the decellularized membrane tissue in an organic solvent, and perform degreasing treatment again under vibration to obtain the degreased membrane tissue;

[0029] Step 4) flattening the degreased membrane tissue, drying and sterilizing to obtain a biofilm.

[0030] Wherein, it should be noted that since the animal membranous tissue itself has a dense layer and a loose layer, the dense layer is formed by densely arranged smaller collagen fiber bundles, which can prevent soft tissue from...

Embodiment 1

[0066] S101, removing the fatty tissue on the surface of the bovine pericardium, cleaning the surface foreign matter, and obtaining the bovine pericardium after preliminary fat removal;

[0067] S102. Soak the bovine pericardium after preliminary degreasing with 5 times the amount of 1M sodium hydroxide for 1.0 h to obtain decellularized bovine pericardium;

[0068] S103. Wash the decellularized bovine pericardium for 15 minutes with 3 parts of phosphate buffer solution whose mass is 15 times that of the decellularized membrane tissue, so that the pH value of the bovine pericardium is 6.0;

[0069] S104, degreasing the bovine pericardium obtained in step S103 with 5 times the amount of isopropanol for 3 hours to obtain degreased bovine pericardium, the fat content of the defatted bovine pericardium is 1.5%;

[0070] S105. Wash the degreased bovine pericardium with 5 parts of water whose mass is 15 times that of the degreased bovine pericardium respectively, so that the mass co...

Embodiment 2

[0075] S101, removing the fat tissue on the surface of the porcine small intestine mucosa, cleaning the foreign matter on the surface, and obtaining the porcine small intestine mucosa after the initial fat removal;

[0076] S102. Soak the pig small intestinal mucosa after preliminary degreasing with 5 times the amount of 0.25M sodium hydroxide for 0.5h to obtain decellularized pig small intestinal mucosa;

[0077] S103. Wash the decellularized porcine small intestinal mucosa for 10 minutes with 3 parts of phosphate buffer solution whose mass is 15 times that of the decellularized membrane tissue, so that the pH value of the porcine small intestinal mucosa is 8.0;

[0078] S104, degreasing the porcine small intestinal mucosa obtained in step S103 with 5 times the amount of isopropanol for 1.5 hours to obtain defatted porcine small intestinal mucosa, the fat content of the defatted porcine small intestinal mucosa is 1.2%;

[0079] S105. Wash the degreased porcine small intestina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com