A method for treating waste clothes

A treatment method and clothing technology, applied in fiber treatment, water/sewage treatment, chemical instruments and methods, etc., can solve problems such as environmental pollution, waste of used clothes, etc., achieve simple and easy process flow, low investment and operation costs, and realize The effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

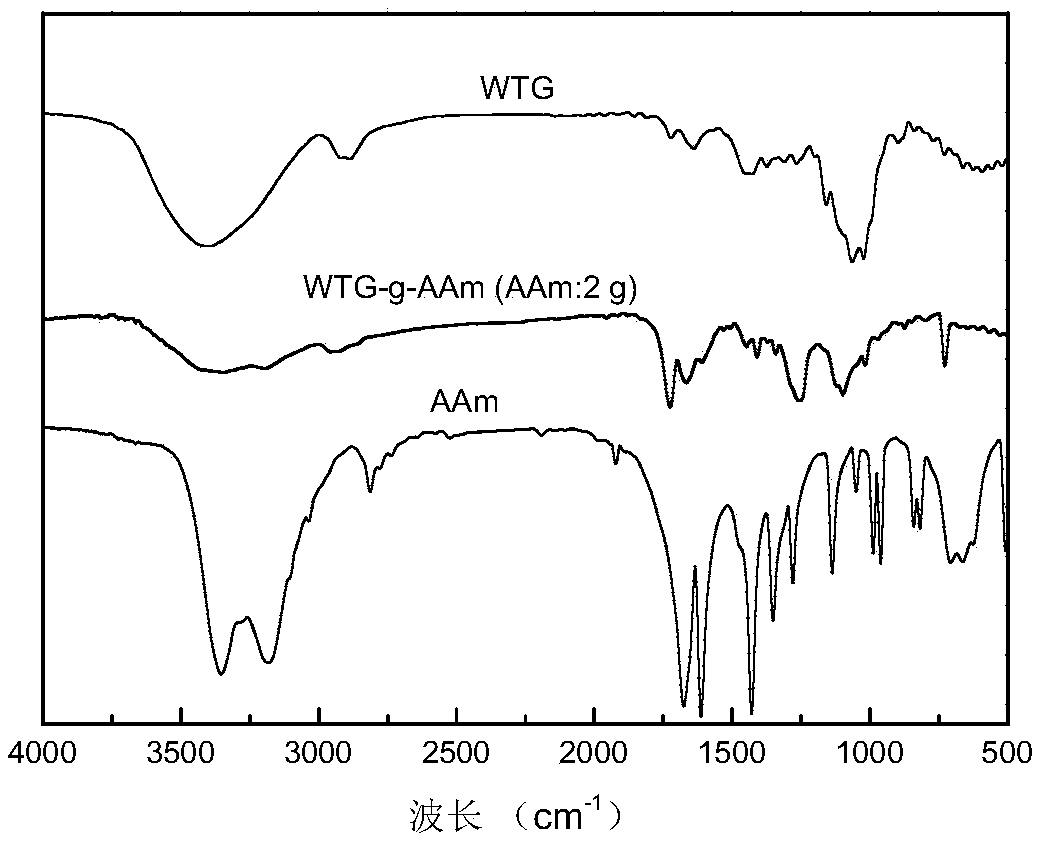

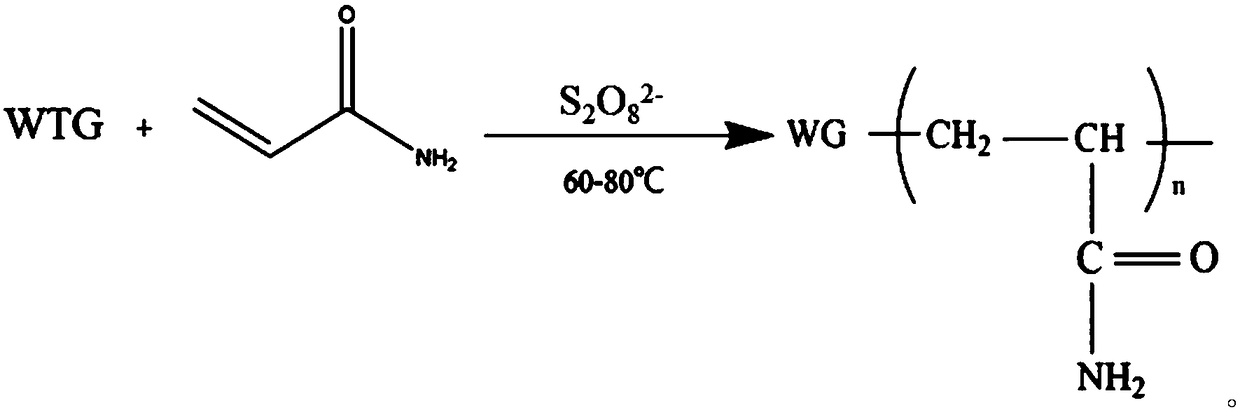

Method used

Image

Examples

Embodiment 1

[0037] (1) Pretreatment of waste clothes

[0038] (1-1) Take discarded cotton fabrics from a university dormitory in Shanghai, and manually cut them into 1cm×1cm pieces;

[0039] (1-2) Place the trimmed pieces in a YB2000-A shearing mill and grind for about 1 hour to obtain flocs;

[0040] (1-3) Put the floc into a QM-1SP04 planetary ball mill for ball milling, the ball milling speed is 400r / min, and the running time is 6h, to obtain a powder with a particle size ranging from about 1 to 400 μm;

[0041] (2) Powder activation

[0042] (2-1). Use an analytical electronic balance to weigh 5 g of waste clothes that are ball-milled into powder in a three-necked flask;

[0043] (2-2). Add 100mL of 64% sulfuric acid into a three-necked flask, and soak the powder for 30min at room temperature;

[0044] (2-3). Place the three-neck flask in a constant temperature water bath, heat it to 55°C, and stir it for 120 minutes under constant temperature conditions, then take it out and cool ...

Embodiment 2

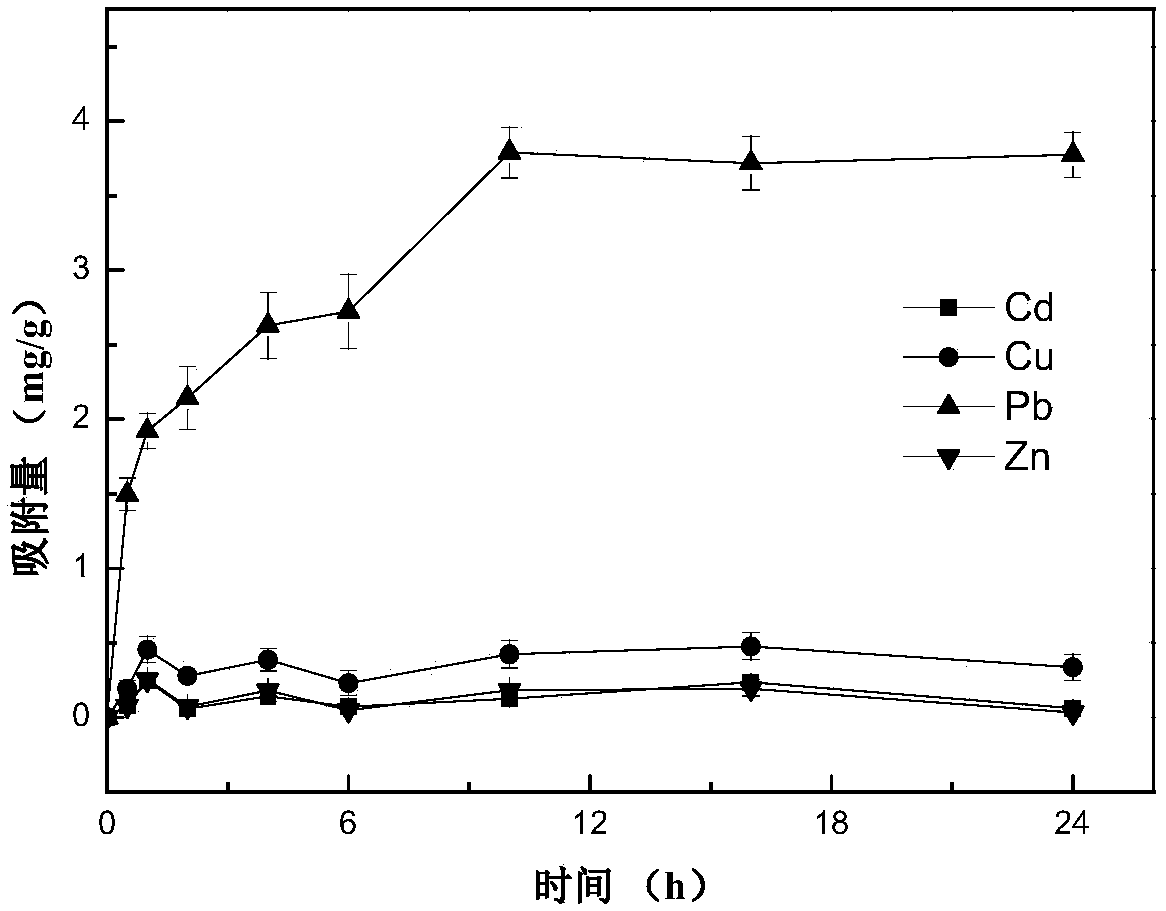

[0055] The adsorbent of the graft copolymerization product is applied to the heavy metal removal experiment, specifically according to the following steps:

[0056] (1) The experimental simulation of heavy metal wastewater is composed of CdCl 2 12H 2 O, Cu(SO 4 ) 2 ·5H 2 O, Pb(NO 3 ) 2 and Zn(NO 3 ) 2 ·6H 2 O, the concentration of the four metal ions in the wastewater is 20mg / L;

[0057] (2) Take the synthesized adsorbent to carry out the heavy metal adsorption experiment, the adsorbent concentration in the wastewater is 2g / L, the adsorption time is 0-24h, and the pH is adjusted to 2-8. The adsorption experiment was carried out in a constant temperature shaker at a rate of 150r / min and a temperature of 25°C;

[0058] (3) Sampling at regular intervals, using an inductively coupled plasma optical emission spectrometer (ICP-OES) to detect the heavy metal content in the sample, and calculating the removal rate of each metal ion.

[0059] In this embodiment, the graft co...

Embodiment 3

[0062] A method for processing waste clothing, specifically comprising the following steps:

[0063] (1) Pretreatment of waste clothes

[0064] (1-1) Take discarded cotton fabrics from a university dormitory in Shanghai, and manually cut them into 1cm×1cm pieces;

[0065] (1-2) Place the trimmed pieces in a YB2000-A shearing mill and grind for about 1 hour to obtain flocs;

[0066] (1-3) Put the floc into a QM-1SP04 planetary ball mill for ball milling, the ball milling speed is 400r / min, and the running time is 6h, to obtain a powder with a particle size ranging from about 1 to 400 μm;

[0067] (2) Powder activation

[0068] (2-1). Use an analytical electronic balance to weigh 5 g of waste clothes that are ball-milled into powder in a three-necked flask;

[0069] (2-2). Add 100mL of 70% sulfuric acid into a three-necked flask, and soak the powder for 20min at room temperature;

[0070] (2-3). Place the three-neck flask in a constant temperature water bath, heat to 40°C, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com