High-performance nano crystal whisker thickener for putty and preparation method of thickener

A nano-whisker, high-performance technology, applied in the field of high-performance nano-whisker thickener for putty powder and its preparation, can solve the problems of poor comprehensive performance, production, storage, construction, film-forming effect of putty powder, etc. Not easy to crack, excellent thickening, prevent bleeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

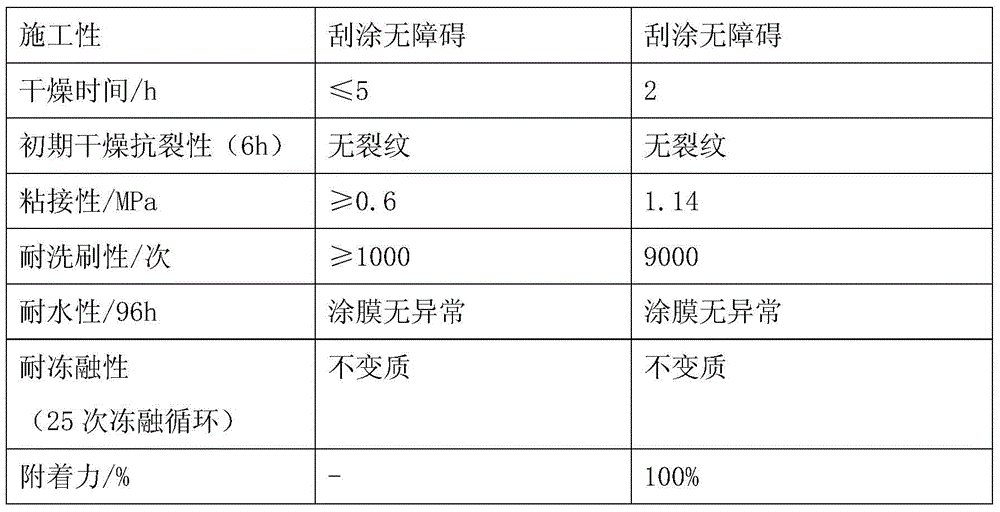

[0016] A high-performance nano-whisker thickener for putty powder, made of the following raw materials by weight (kg): wollastonite 20, siliceous shale 14, fluorite slag 12, ceramic polishing slag 17, rectorite 16 , waste molding sand 12, diatomite 22, red mud 18, salt gypsum 13, magnesite 8, aluminum sulfate 11, calcium silicate 6, petroleum coke powder 4, modifier A 7, modifier B 12;

[0017] Described modifier A is mixed by the raw material of following weight (kg): calcium oxalate 9, copper sulfate 6, sodium sulfide 4, diethylene glycol 8, hydroxyethyl carboxymethyl cellulose 9, sodium oleate 6, Calcium lignosulfonate 4, coconut oil fatty acid diethanolamide 3, ethoxylated fatty acid methyl ester 6;

[0018] The modifier B is mixed from the following raw materials by weight (kg): polyacryloyl dimethyl ammonium taurate 3, hydroxypropyl distarch phosphate 7, dodecyl sulfopropyl betaine 2, Polyether modified silicone oil 5, polyethylene glycol 10, sodium dodecylbenzene sulfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com