Method of converting oxygen-containing raw material into gasoline

A technology of oxygen-containing raw materials and gasoline, which is applied in the direction of biological raw materials, petroleum industry, chemical recovery, etc., can solve the problems of high manufacturing cost and unsuitable for large-scale production, and achieve the reduction of operating energy consumption, investment cost and operational complexity , avoid the effect of switching the regeneration process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

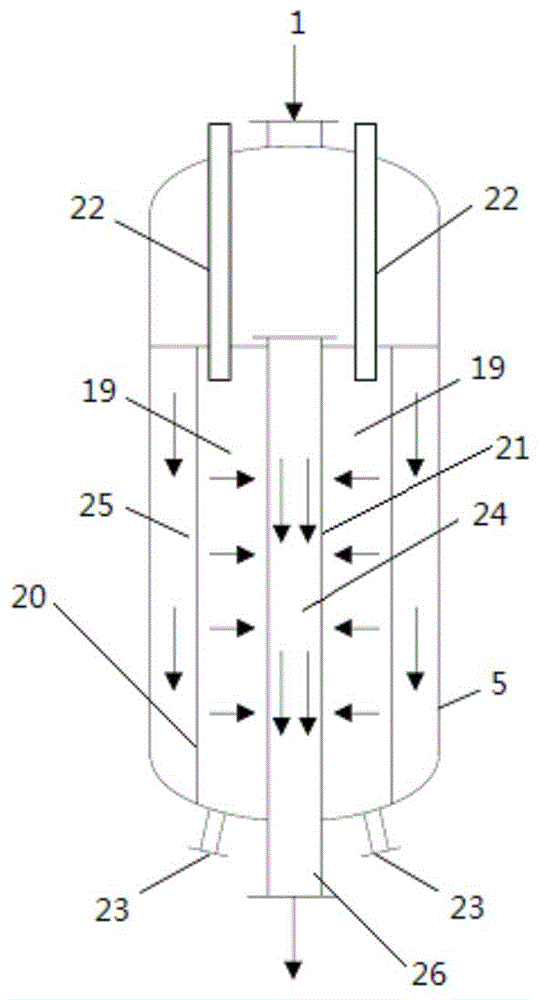

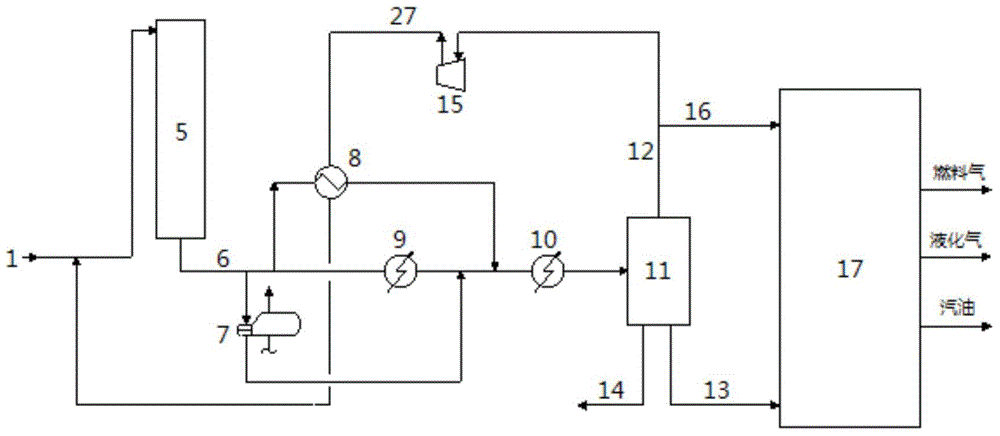

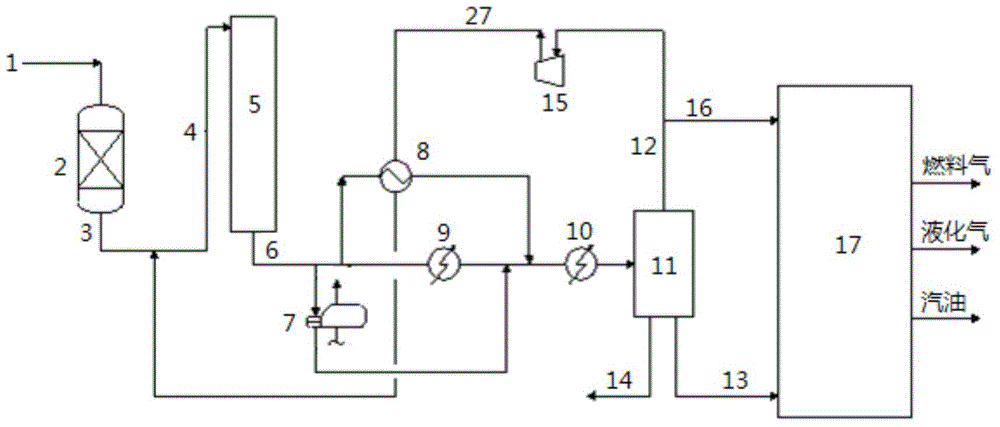

Method used

Image

Examples

Embodiment 1

[0087] The catalyst used in this example was prepared by the following method.

[0088] (1) impregnating powdery ZSM-5 molecular sieve (in the form of Na 2 Na content in terms of O is 0.2% by weight, SiO 2 / Al 2 o 3 (molar ratio) = 100, purchased from Sinopec Changling Catalyst Factory), and the time was 5 hours. The impregnated mixture was dried in an oven at 150° C. for 7 hours; the dried solid powder was calcined in a muffle furnace at 560° C. for 5 hours. After the solid obtained by roasting is crushed and sieved, a phosphorus-containing ZSM-5 molecular sieve is obtained, wherein, P 2 o 5 In total, the phosphorus content was 5% by weight.

[0089] (2) Pseudo-boehmite is mixed with kaolin, and the resulting mixture is formulated into a slurry with deionized water, then the phosphorus-containing ZSM-5 molecular sieves obtained in step (1) are added, after stirring, spray drying is carried out to control The outlet temperature of the spray dryer is in the range of 100-...

Embodiment 2

[0096] Using the same method as in Example 1 to convert methanol into gasoline, the difference is that the catalyst is not loaded in the reactor, but the catalyst is continuously sent into the annular vessel through the catalyst feed pipe arranged at the top of the annular vessel, relying on The gravity of the catalyst itself makes it pass through the annular container and leaves the reactor from the catalyst discharge pipe at the bottom of the annular container, wherein the residence time of the catalyst in the annular container of the reactor is controlled to be 300 hours.

[0097] The reaction was carried out continuously for 300 hours. During the continuous reaction, the conversion rate of methanol and the selectivity of gasoline are listed in Table 1.

Embodiment 3

[0099] Adopt the method identical with embodiment 1 to convert methanol into gasoline, the difference is that the catalyst used is prepared by the following method:

[0100] Mix pseudo-boehmite with kaolin, and prepare the resulting mixture into a slurry with deionized water, then add the same ZSM-5 molecular sieve as the ZSM-5 molecular sieve as raw material in step (1) of Example 1, and stir evenly , carry out spray drying, control the outlet temperature of the spray dryer within the range of 100-110°C, and the material drying time is 2 minutes. The particles obtained by spray drying were calcined at 450° C. for 4 hours to obtain a shaped catalyst containing ZSM-5 (volume average particle diameter of 8 mm), wherein the content of ZSM-5 molecular sieve was 80% by weight, and the content of aluminum oxide was 15% by weight. % by weight, the content of clay is 5% by weight.

[0101] The reaction was carried out continuously for 300 hours. During the continuous reaction, the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com