High-density pellet core and preparation method thereof

A high-density, micro-pill technology, applied in the direction of metabolic diseases, bulk delivery, drug combination, etc., can solve the problems of not meeting energy conservation and environmental protection, low yield rate, cost increase, etc., to achieve drug adhesion and high yield rate , good roundness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

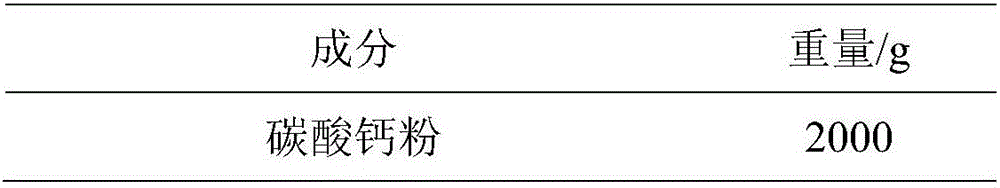

[0034] A high-density medicinal pellet core, the components of the pellet core are listed in Table I.

[0035] Table I

[0036]

[0037]

[0038] Preparation method: Weigh the materials according to the amounts shown in Table I, heat the purified water to about 80°C, slowly add hydroxypropyl methylcellulose E50 to the hot purified water, add while stirring, and wait for the binding liquid to cool to room temperature Stand-by; the weighed calcium carbonate powder and microcrystalline cellulose are placed in the high-efficiency wet mixing granulator, and the calcium carbonate powder is calcium carbonate with a median particle diameter of 4.0 μm, and the mixing speed is set at 300rpm, shear The cutting rate is 1000rpm, and the mixing shear is turned on. After mixing and shearing for 3 minutes, slowly add the adhesive solution. After adding the adhesive solution, set the mixing rate to 300rpm and the shear rate to 1800rpm. After mixing and shearing for 2 minutes, the materia...

Embodiment 2

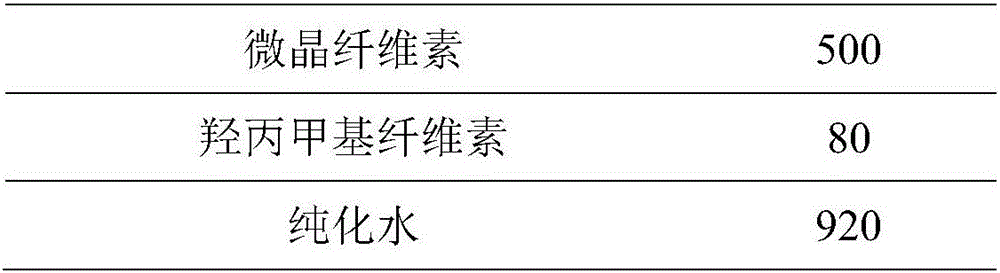

[0040] A high-density medicinal pellet core, the components of the pellet core are listed in Table II.

[0041] Table II

[0042]

[0043] Preparation method: Weigh the materials according to the amounts shown in Table II, slowly add polyethylene glycol 6000 to purified water, add while stirring, wait until the binding liquid becomes clear and transparent for use; add the weighed calcium carbonate Powder and microcrystalline cellulose are placed in a high-efficiency wet mixing granulator, the calcium carbonate powder is calcium carbonate with a median particle size of 30.0 μm, the mixing rate is set to 300 rpm, the shear rate is 1000 rpm, the mixing shear is turned on, and the mixing After shearing for 3 minutes, slowly add the adhesive solution. After adding the adhesive solution, set the mixing rate to 300rpm and the shear rate to 1800rpm. After mixing and shearing for 2 minutes, the material can be discharged to obtain a soft material; then turn on the extrusion spheroni...

Embodiment 3

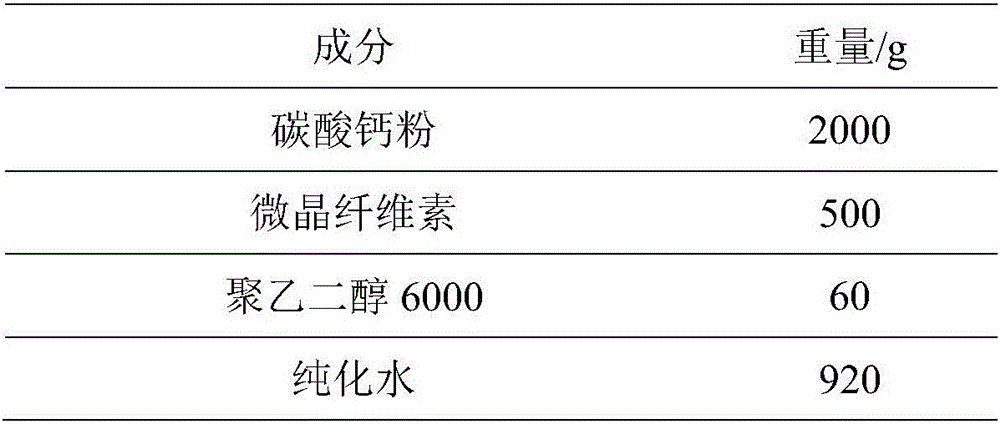

[0045] A high-density medicinal pellet core, the components of the pellet core are listed in Table III.

[0046] Table III

[0047]

[0048] Preparation method: Weigh the materials respectively according to the amounts shown in Table III, slowly add hydroxypropyl cellulose into purified water, add while stirring, wait until the binding liquid becomes clear and transparent for later use; add the weighed calcium carbonate Powder and microcrystalline cellulose are placed in a high-efficiency wet mixing granulator, the calcium carbonate powder is calcium carbonate with a median particle size of 25.0 μm, the mixing rate is set to 300 rpm, the shear rate is 1000 rpm, the mixing shear is turned on, and the mixing After shearing for 3 minutes, slowly add the adhesive solution. After adding the adhesive solution, set the mixing rate to 300rpm and the shear rate to 1800rpm. After mixing and shearing for 2 minutes, the material can be discharged to obtain a soft material; then turn on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com