Method for preparing slow-release antibacterial dressing

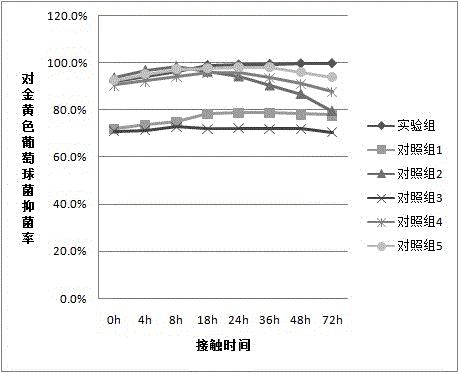

A slow-release, bacterial cellulose technology, used in medical science, absorbent pads, bandages, etc., can solve the problem of short duration of antibacterial, achieve the effect of simple operation, shorten the wound healing period, and promote wound healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

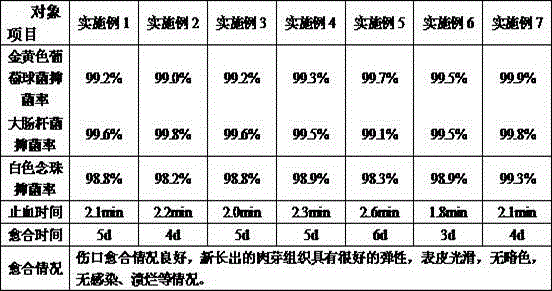

Examples

Embodiment 1

[0037] A preparation method of slow-release antibacterial dressing, the specific steps of the preparation method are as follows:

[0038](1) Treat bacterial cellulose with low-temperature plasma first, and then conduct plasma treatment in an air atmosphere. The voltage of the plasma is 140V, the vacuum degree is 150Pa, and the treatment time is 1min at room temperature; 2g is weighed and treated with low-temperature plasma. Dissolve bacterial cellulose in 100mL of 60wt% isopropanol solution by weight, add 10g of dodecyltriphenylphosphonium chloride solution with 5.0wt% by weight, stir at 40°C for 12h, then cool, and use Washing with acetone, and finally washing repeatedly with distilled water, drying at 70°C to obtain quaternary phosphonium salt / bacterial cellulose;

[0039] (2) Weigh 2g of quaternary ammonium chitosan, dissolve it in 100mL of distilled water, and prepare a quaternary ammonium chitosan solution, then add 0.2g of calcium chloride, stir evenly, and then add 0.5g...

Embodiment 2

[0044] A preparation method of slow-release antibacterial dressing, the specific steps of the preparation method are as follows:

[0045] (1) Treat bacterial cellulose with low-temperature plasma first, and then conduct plasma treatment in an air atmosphere. The voltage of the plasma is 140V, the vacuum degree is 150Pa, and the treatment time is 1min at room temperature; 2g is weighed and treated with low-temperature plasma. Dissolve bacterial cellulose in 100mL of 60wt% isopropanol solution by weight, add 10g of dodecyltriphenylphosphonium chloride solution with 5.0wt% by weight, stir at 40°C for 12h, then cool, and use Washing with acetone, and finally washing repeatedly with distilled water, drying at 70°C to obtain quaternary phosphonium salt / bacterial cellulose;

[0046] (2) Weigh 2g of quaternary ammonium chitosan, dissolve it in 100mL of distilled water, and prepare a quaternary ammonium chitosan solution, then add 0.2g of calcium chloride, stir evenly, and then add 0.5...

Embodiment 3

[0051] A preparation method of slow-release antibacterial dressing, the specific steps of the preparation method are as follows:

[0052] (1) Treat bacterial cellulose with low-temperature plasma first, and then conduct plasma treatment in an air atmosphere. The voltage of the plasma is 140V, the vacuum degree is 150Pa, and the treatment time is 1min at room temperature; 2g is weighed and treated with low-temperature plasma. Dissolve bacterial cellulose in 100mL of 65wt% isopropanol solution by weight, add 8.3g of tetradecyltriphenylphosphonium chloride solution with 6.0wt% by weight, stir at 40°C for 12h, then cool, first Washing with acetone, and finally washing repeatedly with distilled water, drying at 70°C to obtain quaternary phosphonium salt / bacterial cellulose;

[0053] (2) Weigh 2g of quaternary ammonium chitosan, dissolve it in 100mL of distilled water, and prepare a quaternary ammonium chitosan solution, then add 0.2g of calcium chloride, stir evenly, and then add 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com