Preparation method of manganese dioxide cellulose nanofiber mixed compound

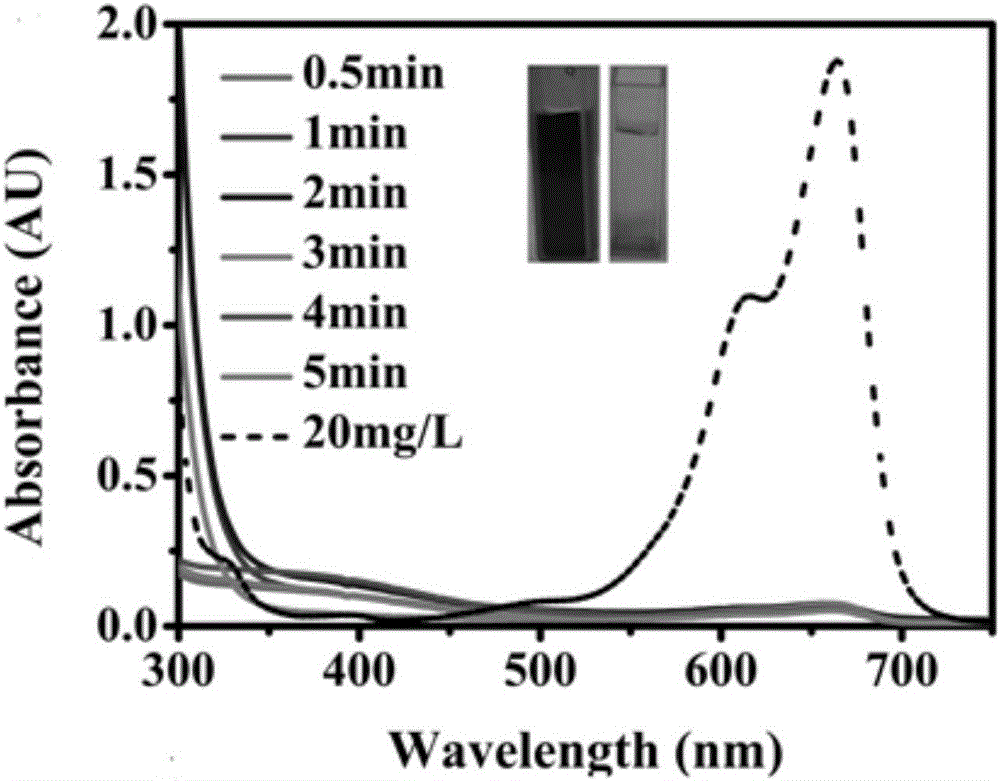

A nanofiber, manganese dioxide technology, applied in chemical instruments and methods, oxidized water/sewage treatment, water pollutants, etc., can solve problems such as reducing the contact area of dyes and decolorizing agents, difficult to recycle decolorizing materials, and reducing decolorization efficiency. , to achieve the effect of good application prospect, high decolorization efficiency and low synthesis cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

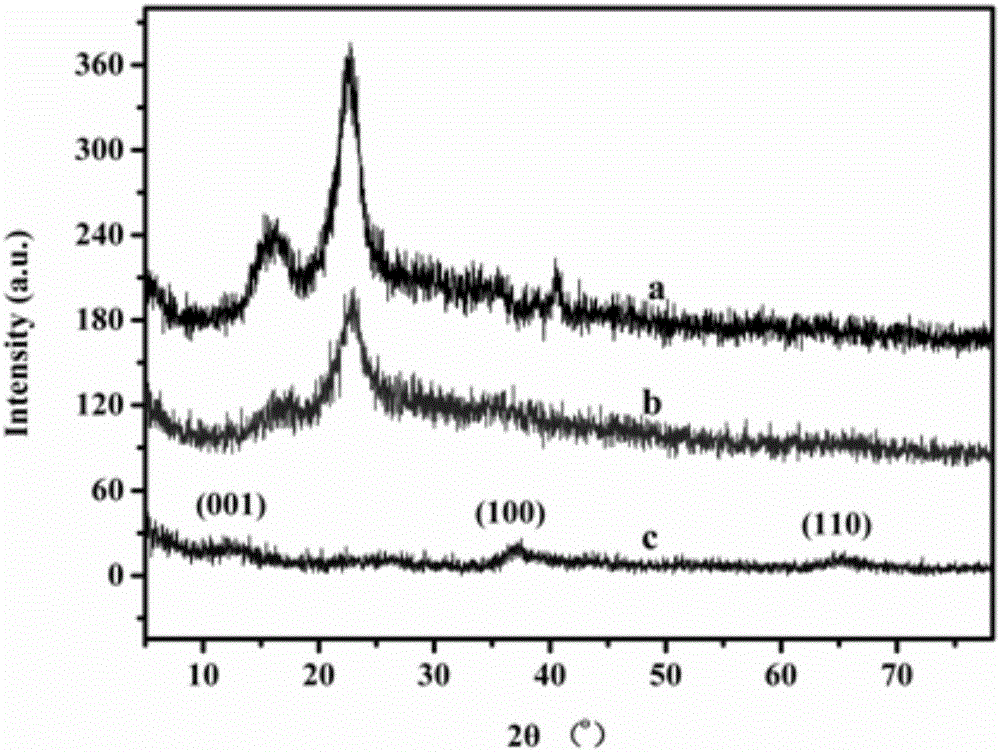

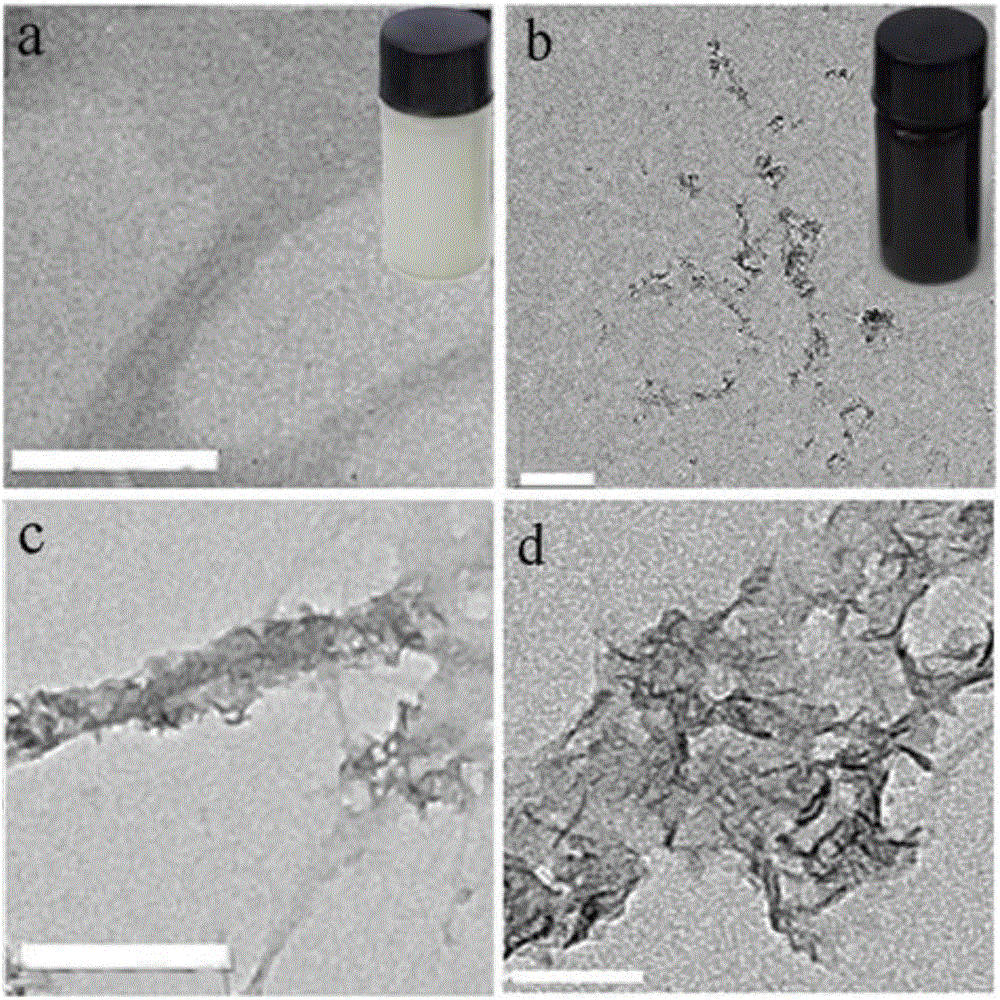

[0021] A method for preparing manganese dioxide cellulose nanofiber hybrids, comprising the following steps:

[0022] (1) Preparation of nanocellulose

[0023] Cellulose suspension was prepared from waste cotton fiber, and ultrasonic cell pulverizer was used to ultrasonicate for 1 hour at 1000w to prepare cellulose nanofibers;

[0024] (2) Preparation of manganese dioxide / cellulose nanofiber hybrid

[0025] Potassium permanganate: the molar ratio of potassium hydroxide=1:1 prepares alkaline potassium permanganate, dissolves 10mmol alkaline potassium permanganate in 100mL water, and adds 300mL 1wt% cellulose nanofibers thereto; Stir at room temperature 8h, washed with water to remove impurities, and concentrated into a slurry with a solid content of 9.3wt%.

Embodiment 2

[0027] A method for preparing manganese dioxide cellulose nanofiber hybrids, comprising the following steps:

[0028] (1) Preparation of nanocellulose

[0029] Prepare cellulose suspension from bamboo pulp and wood pulp cellulose, and use an ultrasonic cell pulverizer to sonicate at 1000w for 1 hour to prepare cellulose nanofibers;

[0030] (2) Preparation of manganese dioxide / cellulose nanofiber hybrid

[0031] Potassium permanganate: the molar ratio of sodium hydroxide=1:1 prepares basic potassium permanganate, dissolves 10mmol basic potassium permanganate in 100mL water, and adds 300mL 1wt% cellulose nanofibers thereto; Stir at room temperature 8h, washed with water to remove impurities, and concentrated into a slurry with a solid content of 9.3wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com