Resource pretreatment technology for desulfurization waste water hardness ions

A technology for desulfurization wastewater and hardness ions, which is applied in gaseous discharge wastewater treatment, multi-stage water treatment, water/sewage multi-stage treatment, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

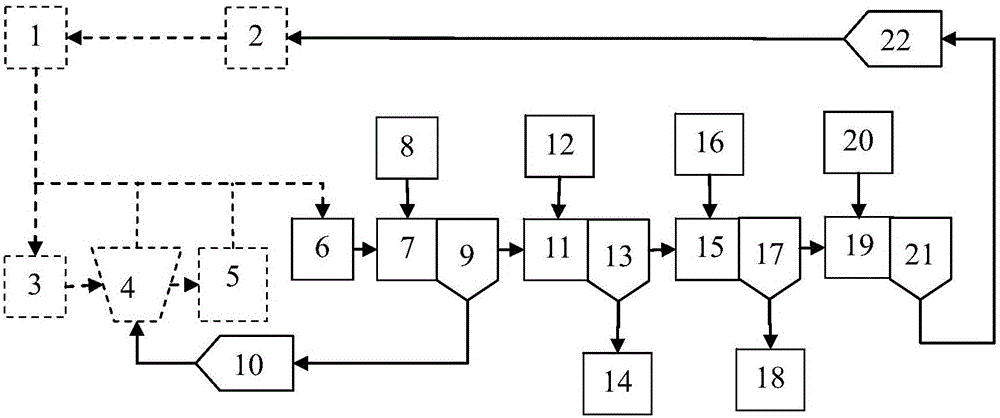

[0038] like figure 1 The specific steps of the desulfurization wastewater resources integrated pretreatment process shown are as follows:

[0039] The desulfurization wastewater discharged from the boiler flue gas wet desulfurization unit is collected in the desulfurization wastewater tank 6, and then enters the pre-coagulation tank 7, where neutralizer A (lime) and coagulant aid (polydimethyldiallyl chloride Ammonium) is added into the pre-coagulation tank 7 from the coagulation dosing tank 8, and the pH value in the wastewater is controlled to be about 7. After mixing evenly, it enters the pre-sedimentation tank 9 to realize solid-liquid separation. After solid-liquid separation, the particles at the bottom of the pre-sedimentation tank 9 are returned to the cyclone 4 in the flue gas desulfurization unit by the first return pump 10 , and the supernatant flows into the first softening tank 11 .

[0040] Sodium hydroxide and lime are added in a ratio of 1:10, and the compound...

Embodiment 2

[0046] A desulfurization wastewater hardness ion resource pretreatment process, specifically comprising the following steps:

[0047] The desulfurization wastewater discharged from the boiler flue gas wet desulfurization unit is collected in the desulfurization wastewater tank 6, and then enters the pre-coagulation tank 7, where neutralizer A (lime) and coagulant aid (polydimethyldiallyl chloride Ammonium) is added into the pre-coagulation tank 7 from the coagulation dosing tank 8, and the pH value in the wastewater is controlled to be about 9. After mixing evenly, it enters the pre-sedimentation tank 9 to realize solid-liquid separation. After solid-liquid separation, the particles at the bottom of the pre-sedimentation tank 9 are returned to the cyclone 4 in the flue gas desulfurization unit by the first return pump 10 , and the supernatant flows into the first softening tank 11 .

[0048] Sodium hydroxide and lime are added in a ratio of 1:2, and the compound softener compo...

Embodiment 3

[0054] The desulfurization wastewater discharged from the boiler flue gas wet desulfurization unit is collected in the desulfurization wastewater tank 6, and then enters the pre-coagulation tank 7, where neutralizer A (lime) and coagulant aid (polydimethyldiallyl chloride Ammonium) is added into the pre-coagulation tank 7 from the coagulation dosing tank 8, and the pH value in the wastewater is controlled to be about 8. After mixing evenly, it enters the pre-sedimentation tank 9 to realize solid-liquid separation. After solid-liquid separation, the particles at the bottom of the pre-sedimentation tank 9 are returned to the cyclone 4 in the flue gas desulfurization unit by the first return pump 10 , and the supernatant flows into the first softening tank 11 .

[0055] Sodium hydroxide and lime are added in a ratio of 1:5, and the compound softener composed of coagulant aid (polydimethyldiallyl ammonium chloride) is mixed uniformly in the first dosing box 12 After that, it is ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com