Taurine preparation method

A technology of taurine and taurine, which is applied in the preparation of sulfonic acid, preparation of sulfonate, chemical instruments and methods, etc., can solve the problem of increased labor intensity of sulfate solid waste, limitation of one-time extraction rate, and failure of normal production. and other problems, to achieve the effect of being beneficial to large-scale industrial production, improving the utilization rate of raw materials and product yield, and avoiding the generation of solid waste salt sodium sulfate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

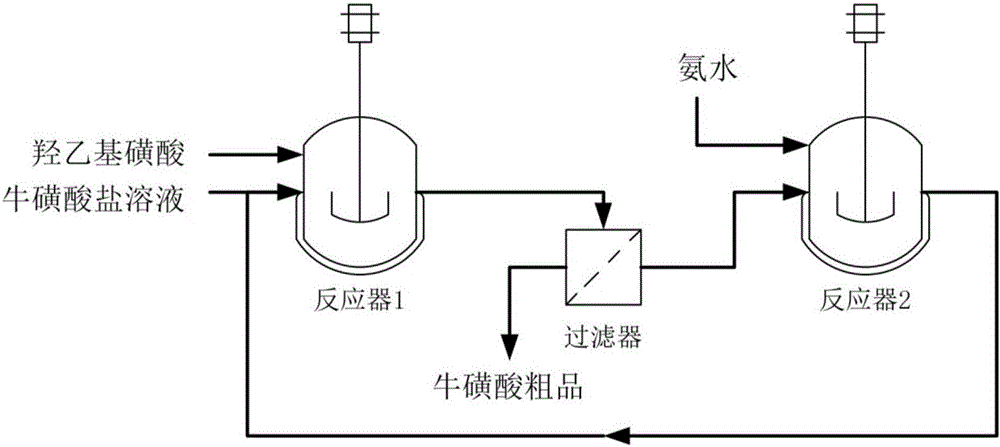

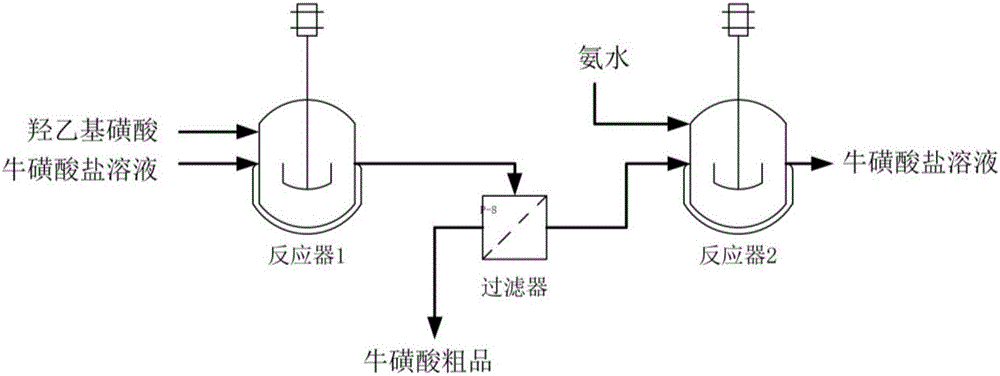

Method used

Image

Examples

Embodiment 1

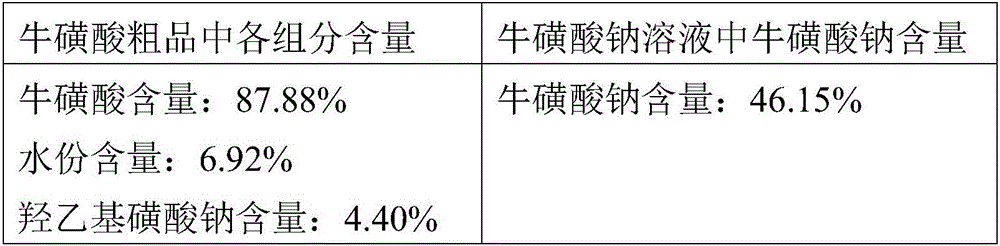

[0043] Take 500 mL of sodium taurine aqueous solution with a mass percentage of 46% in a reaction flask, slowly add isethionic acid under stirring at room temperature until the pH is 5.5 to stop, lower the system temperature to 15°C and filter to obtain 216 g of crude taurine , the filtrate was moved into the reaction bottle, and then this filtrate was supplemented with 1710g of ammonia water with a concentration of 26.5%, heated to 250°C in a high-pressure reactor, and the pressure was 10MPa, reacted for 1 hour, cooled and discharged, evaporated to catch ammonia, and obtained 697g taurine Sodium acid solution. The taurine content was determined by HPLC, and the sodium isethionate content was determined by ion chromatography; the results are shown in Table 1, and the percentages in the table are all mass percentages.

[0044] Table 1

[0045]

Embodiment 2

[0047] Take 500 mL of the sodium taurine solution obtained in Example 1 in a reaction flask, slowly add isethionic acid to stop at pH 7.5 under stirring at room temperature, lower the temperature of the system to 15° C. and filter to obtain 229 g of crude taurine, and the filtrate Move it into the reaction bottle, then add 1700g of ammonia water with a concentration of 25.8% to the filtrate, heat it to 253°C in a high-pressure reactor, and the pressure is 10.5MPa, react for 1 hour, cool down and discharge, evaporate to catch ammonia, and get 615g of taurine sodium solution. The taurine content was determined by HPLC, and the sodium isethionate content was determined by ion chromatography; the results are shown in Table 2, and the percentages in the table are all mass percentages.

[0048] Table 2

[0049]

Embodiment 3

[0051] Take 500 mL of sodium taurine solution with a mass percentage of 46% in a reaction flask, slowly add isethionic acid under stirring at room temperature until the pH is 8.5 to stop, lower the temperature of the system to 15° C. and filter to obtain 223 g of crude taurine. The filtrate was moved into a reaction bottle, and then 1690 g of ammonia water with a concentration of 26.0% was added to the filtrate, heated to 256 ° C in a high-pressure reactor, and the pressure was 10.5 MPa, and reacted for 1 hour, cooled and discharged, and evaporated to catch ammonia to obtain 580 g of taurine Sodium acid solution. The taurine content was determined by HPLC, and the sodium isethionate content was determined by ion chromatography; the results are shown in Table 3, and the percentages in the table are all mass percentages.

[0052] table 3

[0053]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com