Intelligent microgel achieving linear temperature response and preparation method thereof

A temperature-responsive, micro-gel technology, applied in the field of functional materials, can solve problems such as cumbersome synthesis process, complex structure, and restrictions on practical application, and achieve the effect of simple method process, simple preparation conditions, and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 0.351 g methoxy ethyl acrylate, 0.144 g methoxy oligoethylene glycol acrylate ( M n = 480), 0.015 g polyethylene glycol diacrylate ( M n = 258) and 0.02 g sodium dodecyl sulfonate were dissolved in 9 g deionized water, and the mixture was in N 2 Stir at room temperature for 10 min under protection, and then seal at 70 °C; after the temperature stabilizes, inject 1 ml of potassium persulfate aqueous solution (0.75 wt%) into the reaction solution through a syringe to initiate polymerization; the reaction is continued under nitrogen It was carried out under protection for 4 h, and then naturally cooled to room temperature; the microgel obtained by the reaction was purified by dialysis to remove impurities, and a linear temperature-responsive microgel was obtained.

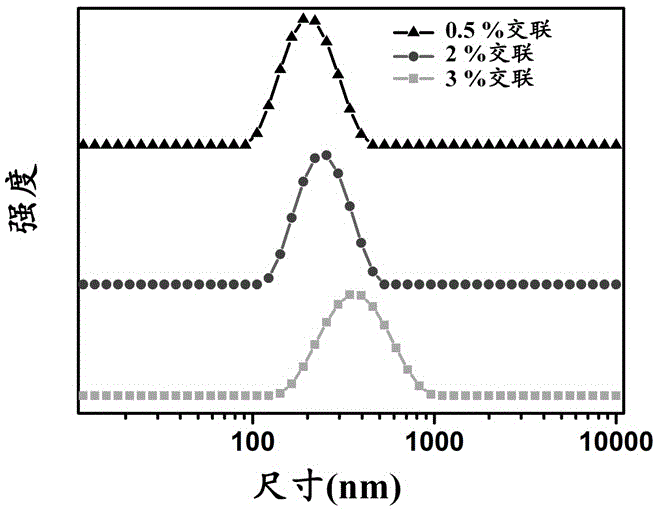

[0024] from figure 1 It can be seen that the obtained microgels exhibit a unimodal distribution, and the distribution is narrow.

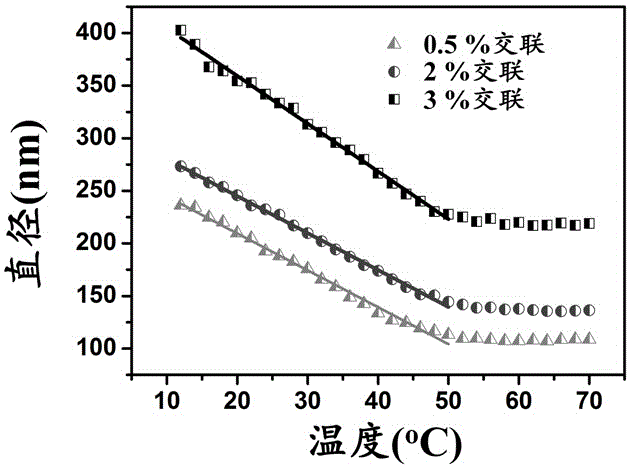

[0025] from figure 2 It can be seen that the prepared microgel showed a ...

Embodiment 2

[0027] 0.351 g methoxy ethyl acrylate, 0.144 g methoxy oligoethylene glycol acrylate ( M n = 480), 0.004 g polyethylene glycol diacrylate ( M n = 258) and 0.02 g sodium dodecyl sulfonate were dissolved in 9 g deionized water, and the mixture was in N 2 Stir at room temperature for 10 min under protection, and then seal at 70 °C; after the temperature stabilizes, inject 1 ml of potassium persulfate aqueous solution (0.75 wt%) into the reaction solution through a syringe to initiate polymerization; the reaction is continued under nitrogen It was carried out under protection for 4 h, and then naturally cooled to room temperature; the microgel obtained by the reaction was purified by dialysis to remove impurities, and a linear temperature-responsive microgel was obtained.

Embodiment 3

[0029] 0.351 g methoxy ethyl acrylate, 0.144 g methoxy oligoethylene glycol acrylate ( M n = 480), 0.015 g polyethylene glycol diacrylate ( M n = 258), 0.005 g of acrylic acid and 0.02 g of sodium dodecylsulfonate were dissolved in 9 g of deionized water, and the mixture was placed in N 2 Stir at room temperature for 10 min under protection, and then seal at 70 °C; after the temperature stabilizes, inject 1 ml of potassium persulfate aqueous solution (0.75 wt%) into the reaction solution through a syringe to initiate polymerization; the reaction is continued under nitrogen It was carried out under protection for 4 h, and then naturally cooled to room temperature; the microgel obtained by the reaction was purified by dialysis to remove impurities, and a microgel with both pH and linear temperature response was obtained.

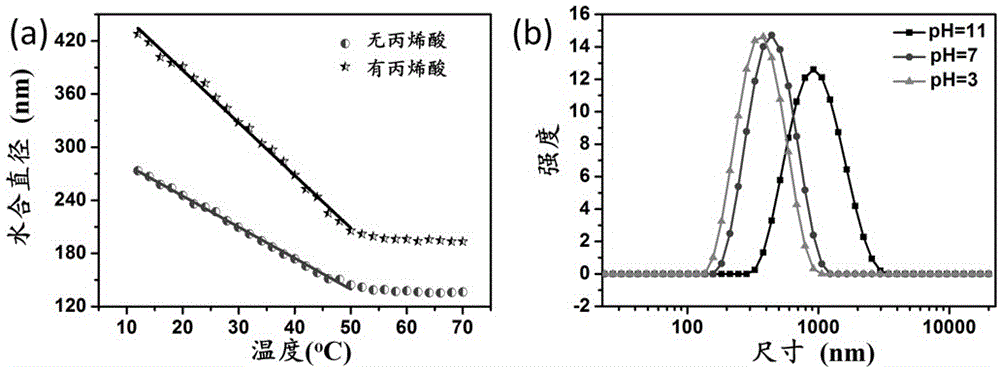

[0030] from image 3 It can be seen that after the introduction of comonomer acrylic acid in the microgel preparation process, the obtained microgel has b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com