Foaming agent, preparation method and application

A foaming agent and auxiliary foaming agent technology, applied in the field of rubber and plastics, can solve the problems of reducing the amount of ammonia released from foamed products, short vulcanization time of the rubber compound, and the amount of ammonia cannot reach the time-weighted concentration, etc. Difficult to disperse, shorten vulcanization time, fine and uniform pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A: The formula of foaming agent

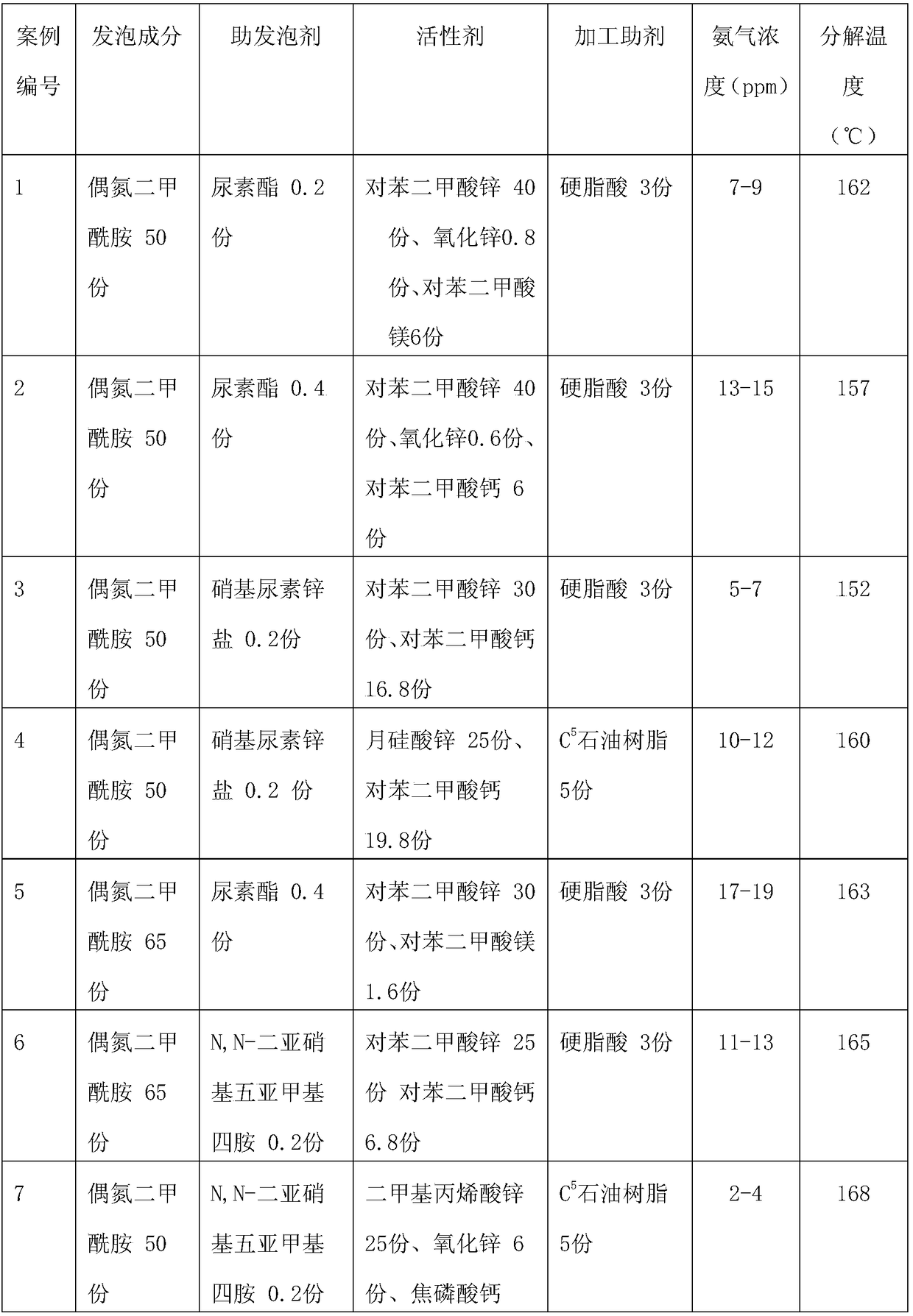

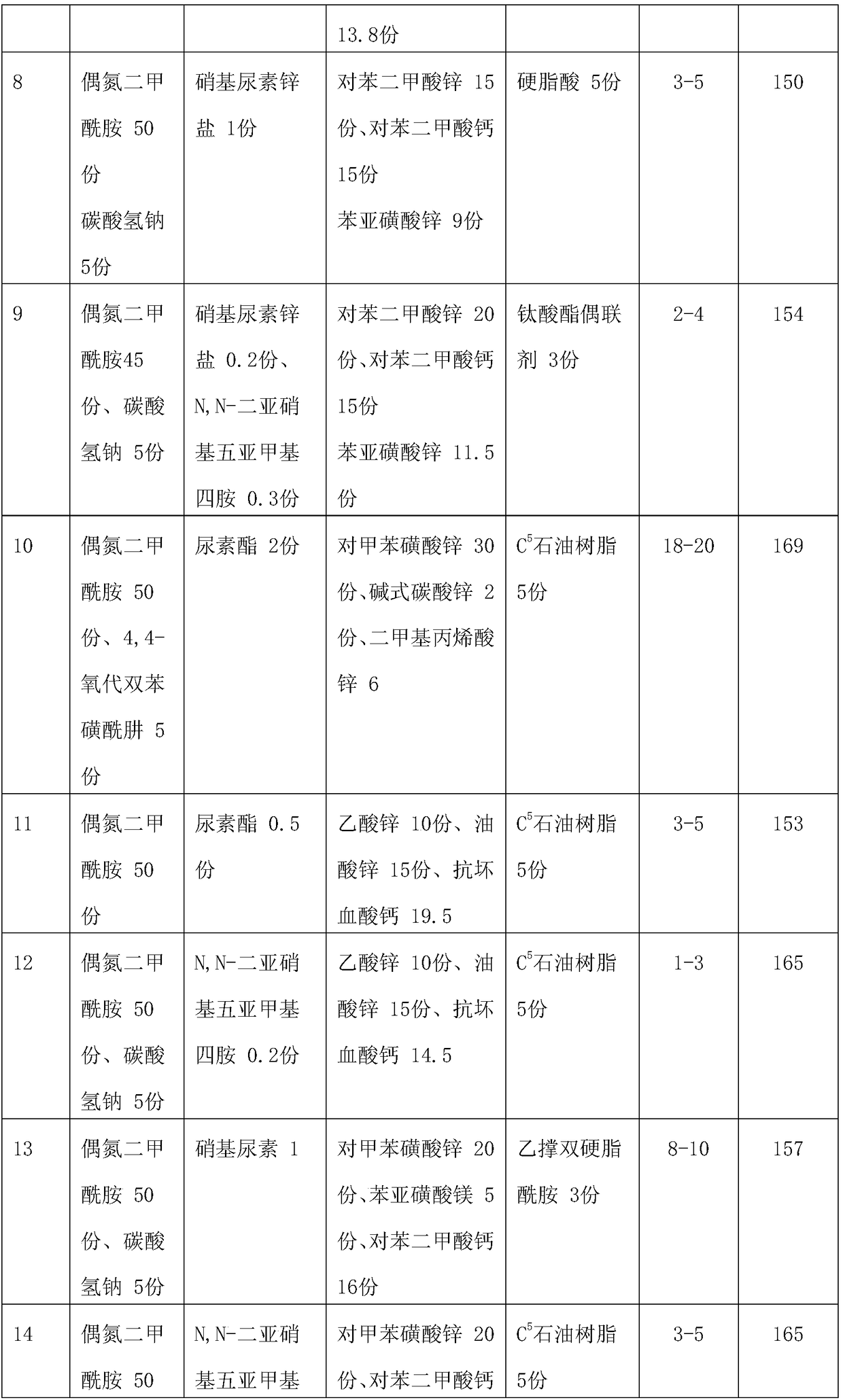

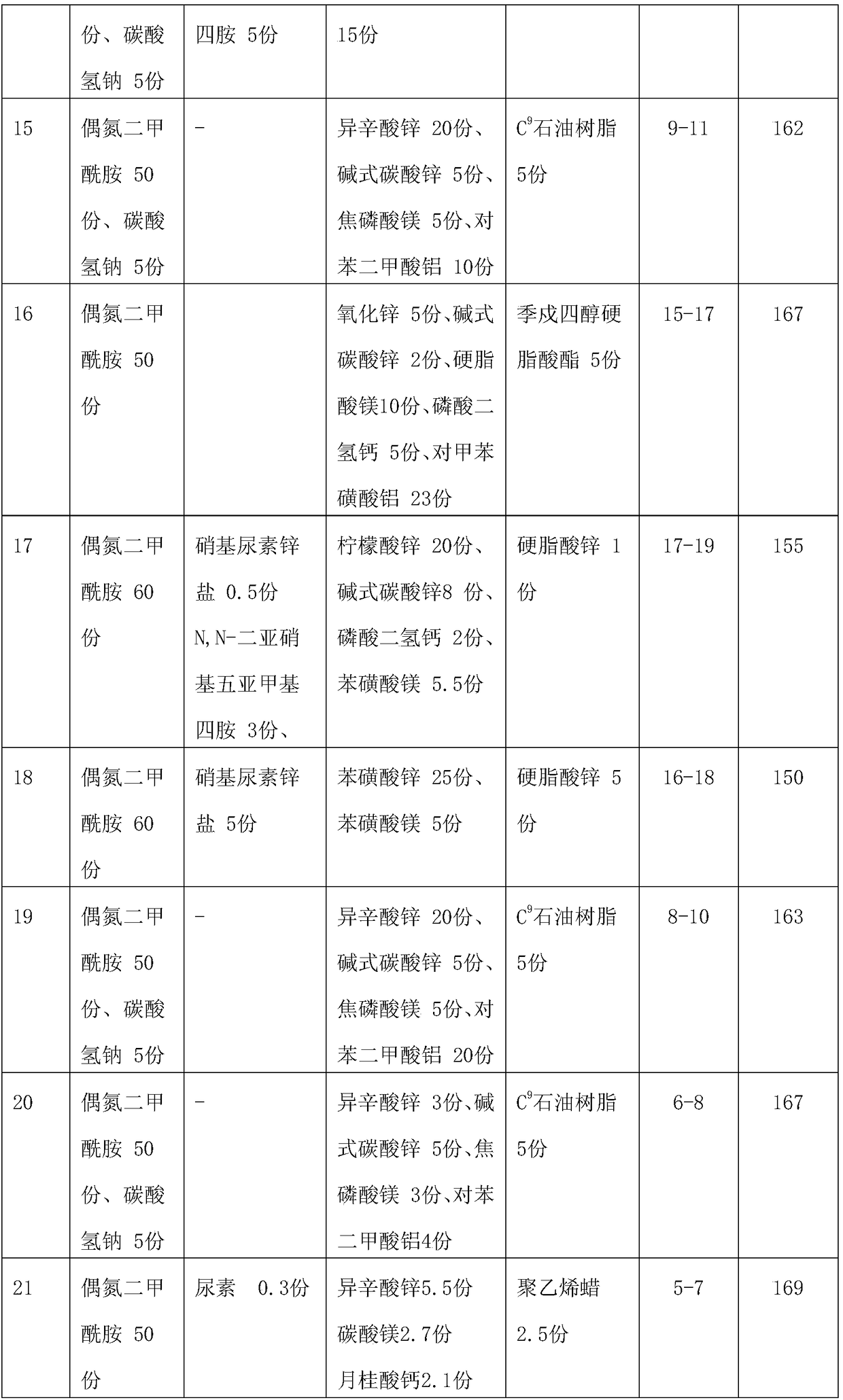

[0032] A foaming agent, the raw materials of which consist of: 50-65 parts of foaming components, 0-5 parts of foaming aids, 15-50 parts of active agents and 1-5 parts of processing aids; For the specific substances and dosages (parts by mass) of foam components, foaming aids, active agents and processing aids, see No. 1-23 in Table 1. No. 1-23 provides 23 foaming agent formulas and each formula test results.

[0033] B: Preparation of foaming agent

[0034] (1) Grind the foaming components and auxiliary foaming agent to more than 1000 mesh with a jet mill; grind the active agent to more than 300 mesh first, then use a cantilever double-helix conical mixer to mix evenly, and finally grind the mixture by jet The machine is crushed to more than 1500 mesh; solid and powder processing aids should first be crushed to more than 400 mesh by a mechanical pulverizer.

[0035] (2) Add the material obtained in step 1) into a cantilever double-h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com