Composite heat-insulating paint for exterior walls and preparation method of composite heat-insulating paint

An external wall, slow technology, applied in the field of paint, can solve the problems of poor durability, poor anti-fouling, unable to prevent the flow of heat, and inconspicuous heat insulation effect, achieve good decoration, good social and environmental benefits, improve life and The effect of stain resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

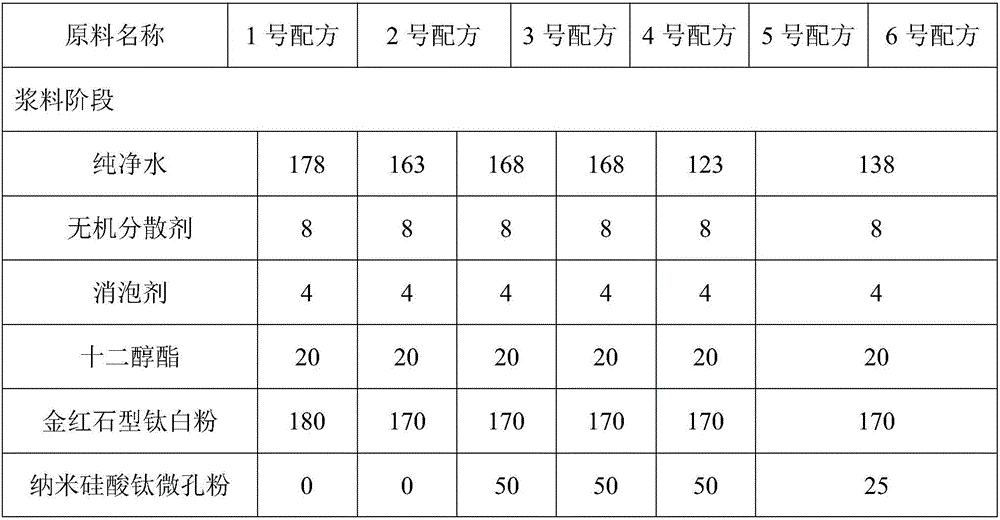

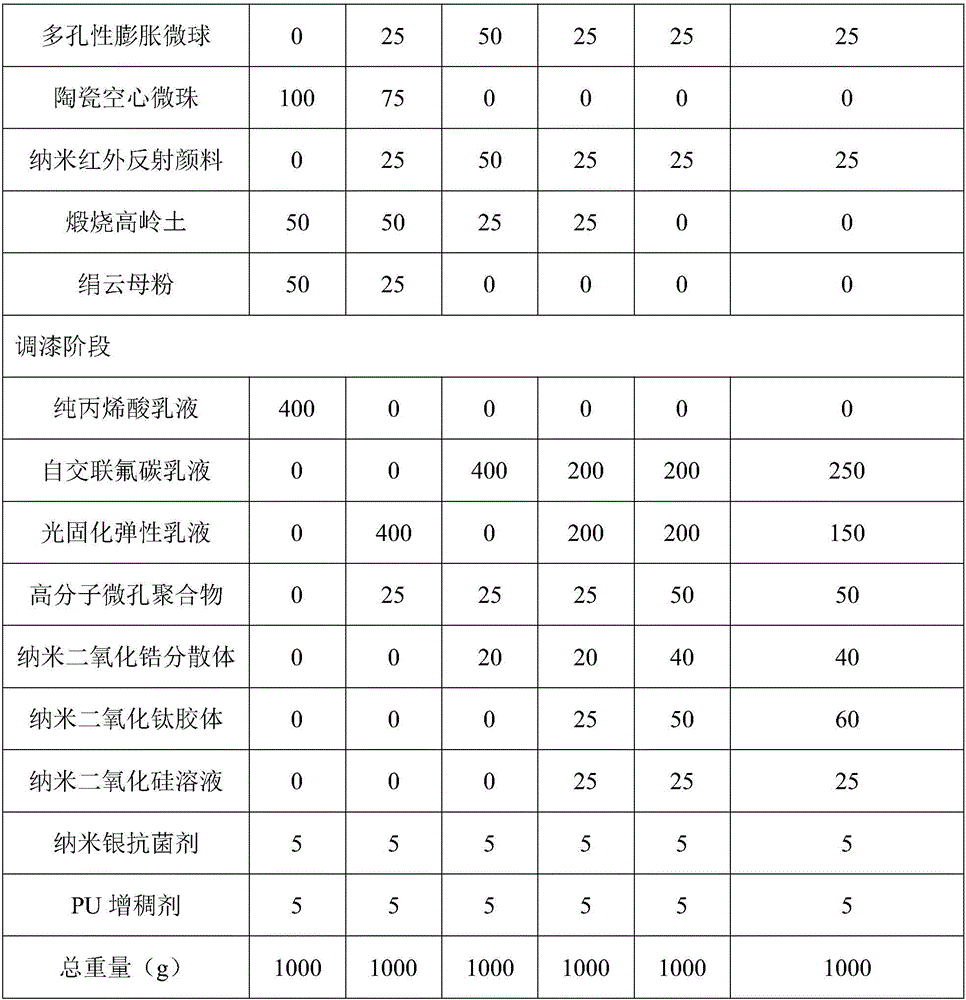

[0023] Composite thermal insulation paint formulation optimization test (unit: g)

[0024]

[0025]

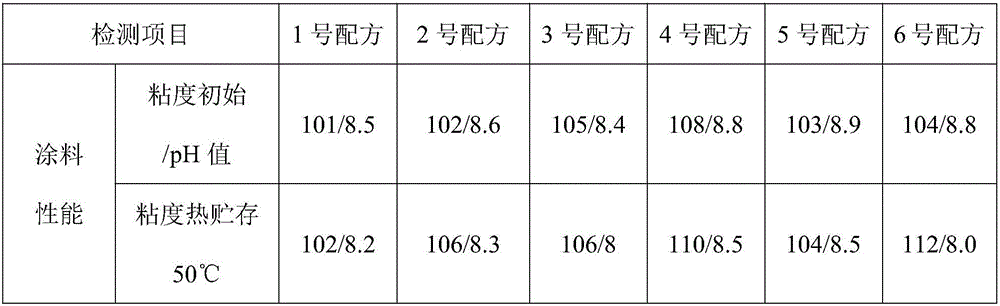

[0026] 2. The test data is as follows:

[0027]

[0028]

[0029]

[0030] Reference testing standards: GB / T 9755-2014, G / T 172-2005, JG / T 235-2014, JG / T 210-2007, GB 24408-2009

[0031] 3. Test analysis

[0032] No. 1 formula: original formula, disadvantages: low solar reflectance, average hemispheric reflectance, high change rate of solar reflectance after pollution, average crack resistance and water resistance.

[0033] Advantages: low cost, good color development, and convenient source of raw materials.

[0034] Formula No. 2: Use elastic emulsion instead. Disadvantages: Poor stain resistance, poor heat insulation durability after pollution, and general heat insulation index.

[0035] Advantages: good elasticity and crack resistance, good water resistance.

[0036] Formula No. 3: Introduce high weather resistance fluorocarbon emulsion, use nano-titanium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com