Flame retardant paint and preparation method thereof

A technology of fire-resistant coatings and raw materials, applied in fire-resistant coatings, anti-corrosion coatings, coatings, etc., can solve the problems of film surface adhesion, adhesion, resistance to burning, weathering and corrosion resistance, etc., to increase resistance to optical pollution properties, good weathering and corrosion resistance, and excellent optical pollution resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

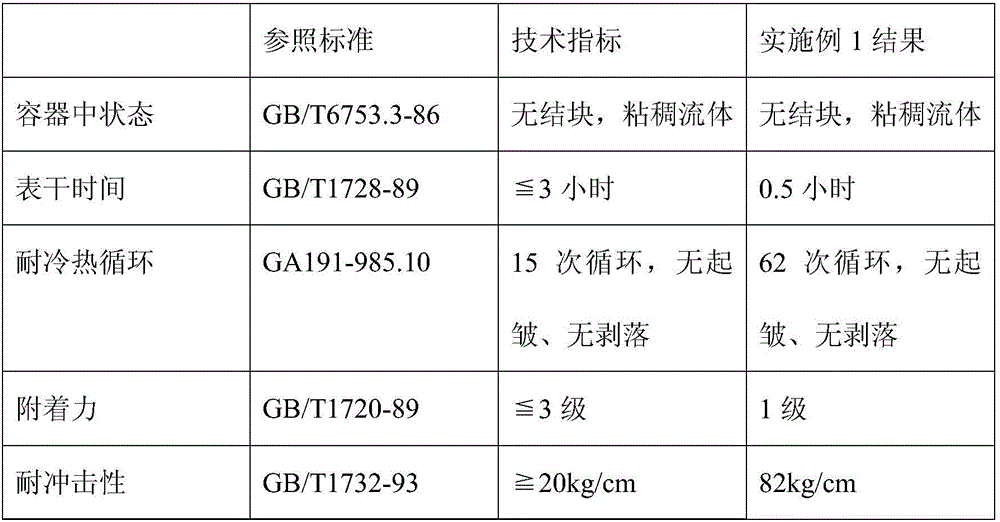

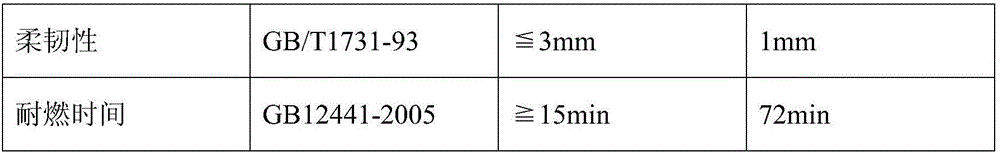

Embodiment 1

[0016] A kind of fireproof coating, is made of the following raw materials by weight: 70 parts of vinegar-acrylic emulsion, 30 parts of styrene-acrylic emulsion, 8 parts of cellulose ether, 10 parts of glass beads, 3 parts of expanded graphite, 3 parts of hydrogenated castor oil, phenolic 20 parts of propane epoxy resin, 5 parts of ammonium polyphosphate, 5 parts of pentaerythritol, 2 parts of zinc borate, 6 parts of butyl latex, 3 parts of sodium fluorosilicate, 6 parts of quartz sand, 3 parts of wood fiber, modified andalusite powder 12 parts, 15 parts of modified clay.

[0017] The modified andalusite powder is prepared by the following method: soak andalusite in 10% hydrochloric acid for 4 hours, wash with deionized water, and then calcined at 400°C for 4 hours, after cooling, soak in 10% hydrogen peroxide solution for 4 hours , washed with deionized water until neutral, dried, and then added 1% of its weight of VAE emulsion, 2% of furan resin, 2% of dibutyltin dilaurate, ...

Embodiment 2

[0024] A kind of fireproof coating, is made of the following raw materials by weight: 80 parts of vinegar-acrylic emulsion, 25 parts of styrene-acrylic emulsion, 9 parts of cellulose ether, 12 parts of glass beads, 4 parts of expanded graphite, 2 parts of hydrogenated castor oil, phenolic 25 parts of propane epoxy resin, 5 parts of ammonium polyphosphate, 6 parts of pentaerythritol, 3 parts of zinc borate, 7 parts of butyl latex, 3 parts of sodium fluorosilicate, 7 parts of quartz sand, 4 parts of wood fiber, modified andalusite powder 14 parts, 12 parts of modified pottery clay.

[0025] The modified andalusite powder is prepared by the following method: soak andalusite in 12% hydrochloric acid for 4 hours, wash with deionized water, and then calcined at 450°C for 5 hours, after cooling, soak in 12% hydrogen peroxide solution for 4 hours , washed with deionized water to neutral, dried, and then added 2% of its weight of VAE emulsion, 3% of furan resin, 2% of dibutyltin dilaur...

Embodiment 3

[0032] A kind of fireproof coating, is made from the raw material of following parts by weight: 90 parts of vinegar-acrylic emulsion, 20 parts of styrene-acrylic emulsion, 10 parts of cellulose ether, 15 parts of glass beads, 5 parts of expanded graphite, 4 parts of hydrogenated castor oil, phenolic 30 parts of propane epoxy resin, 6 parts of ammonium polyphosphate, 6 parts of pentaerythritol, 3 parts of zinc borate, 8 parts of butyl latex, 3 parts of sodium fluorosilicate, 8 parts of quartz sand, 5 parts of wood fiber, modified andalusite powder 15 parts, 10 parts of modified pottery clay.

[0033] The modified andalusite powder is prepared by the following method: soak andalusite in 13% hydrochloric acid for 3 hours, wash with deionized water, and then calcined at 500°C for 4 hours, after cooling, soak in 15% hydrogen peroxide solution for 3 hours , washed with deionized water until neutral, dried, and then added 2% of its weight of VAE emulsion, 3% of furan resin, 2% of dib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com