Method for producing hydrogen from residual sludge by anaerobic fermentation and microbial electrolysis cell coupling

A microbial electrolysis cell and residual sludge technology, applied in fermentation, sludge treatment, chemical instruments and methods, etc., can solve the problems of fermentation obstacles, inability to be used by fermentation bacteria, incomplete fermentation of organic matter to produce gas, etc., and achieve convenient operation , The reactor structure is compact, and the effect of overcoming fermentation obstacles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

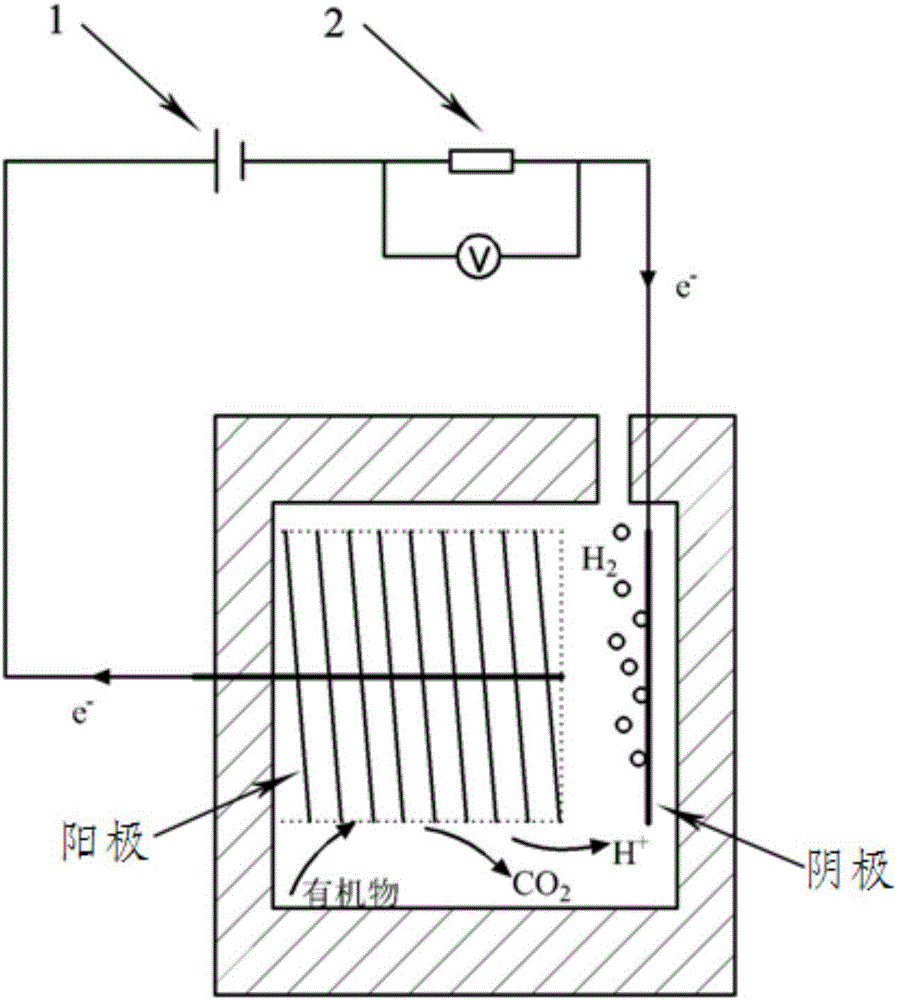

Method used

Image

Examples

Embodiment 1~ Embodiment 5

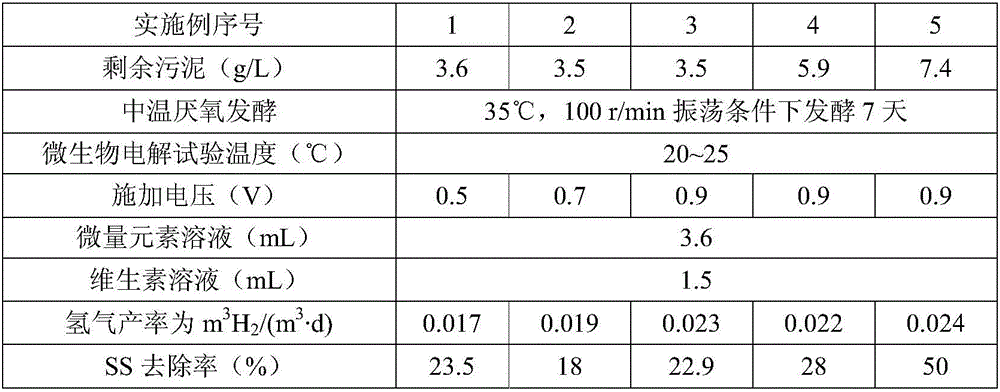

[0040] According to the above-mentioned steps, the parameters of various examples for realizing hydrogen production from excess sludge by coupling mesophilic anaerobic fermentation with microbial electrolysis cell are as follows:

[0041]

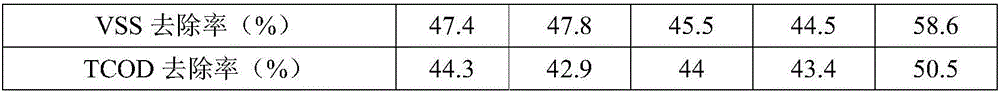

[0042]

[0043] It can be seen from the table that the hydrogen production rate of the residual sludge pretreated by mesophilic anaerobic fermentation in the microbial electrolytic cell is 0.017-0.024m 3 h 2 / (m 3 · d), realizing resource utilization of excess sludge.

[0044] At room temperature of 20-25°C, the removal rate of suspended solid SS is 18%-50%, the removal rate of volatile suspended solid VSS is 44.5%-58.6%, and the removal rate of total chemical oxygen demand TCOD is 42.9%-50.5%. It shows that the method of the present invention realizes the stabilization of sludge on the basis of reducing the amount of excess sludge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com