Embedded ultrasonic motor drive controller

A drive controller, ultrasonic motor technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the problem of poor matching effect, low control accuracy, driving mode and Control strategy description is less and other problems, to achieve the effect of improving versatility, optimizing control parameters, and facilitating human-computer interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in detail below in conjunction with accompanying drawing:

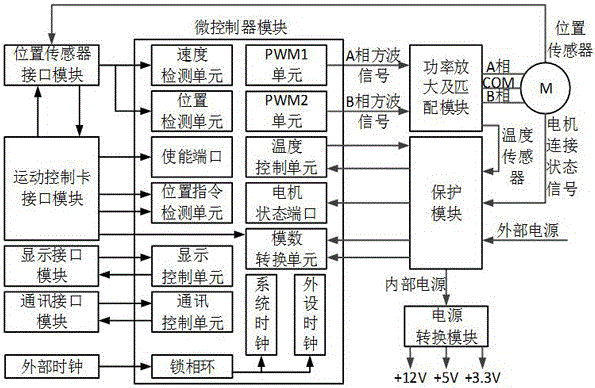

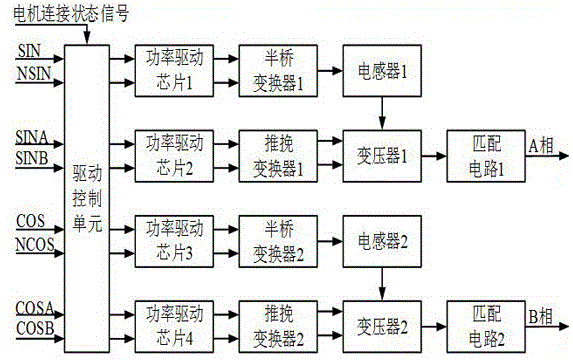

[0020] Such as figure 1As shown, the embedded ultrasonic motor drive controller in this embodiment includes an external clock, a microcontroller module, a power amplification and matching module, a position sensor interface module, a motion control card interface module, a protection module, a display interface module, and a communication interface module and power conversion modules. The external clock is generated by an oscillator composed of a crystal / ceramic resonator, and provides a clock signal for the system clock and the peripheral clock in the microcontroller module after being frequency multiplied by the phase-locked loop in the microcontroller module. The clock signal provides a time reference for the PWM1 unit and the PWM2 unit in the microcontroller module. The PWM1 unit generates an A-phase square wave signal and generates an A-phase drive signal through the pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com