Wet-mixed mortar additive capable of enhancing early strength of mortar

An early-strength, wet-mixed mortar technology, applied in the field of building materials, can solve problems such as no guidance plan, achieve the effects of shortening the time, prolonging the operable time, and improving the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

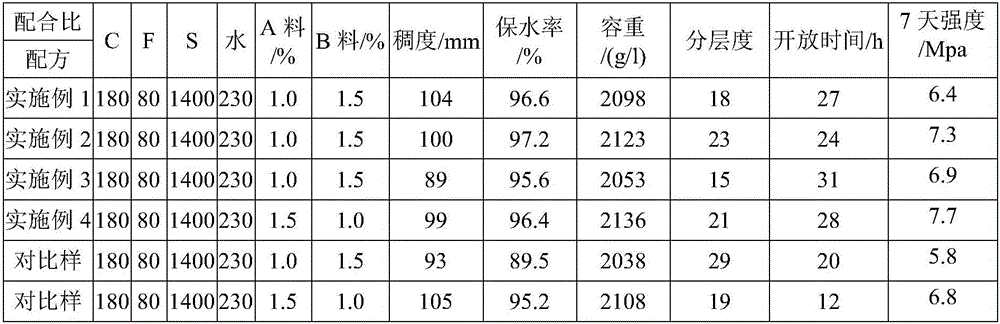

Embodiment 1

[0021]Embodiment 1: The wet-mixed mortar admixture of the present invention that can improve the early strength of mortar is composed of material A (improving workability and water retention) and material B (opening time regulator). Wherein: the A material is made of the following components and weight (mass) ratio of raw materials: multifunctional water retention agent 320g, shrinkage reducing agent (polyvinyl alcohol) 30g, Brunei glue 3g, water 647g. The weight sum of each component in the above-mentioned A material is 1000g. The B material is made from the raw materials of the following components and weight (mass) ratio: 200g of sugar retarder (wherein sucrose 100g, citric acid 100g), organophosphorus retarder (hydroxyethylidene Diphosphonic acid) 200g, air-entraining agent (AE-200 type polyether concrete high performance air-entraining agent) 20g, water 580g. The weight sum of each component in the above-mentioned B material is 1000g.

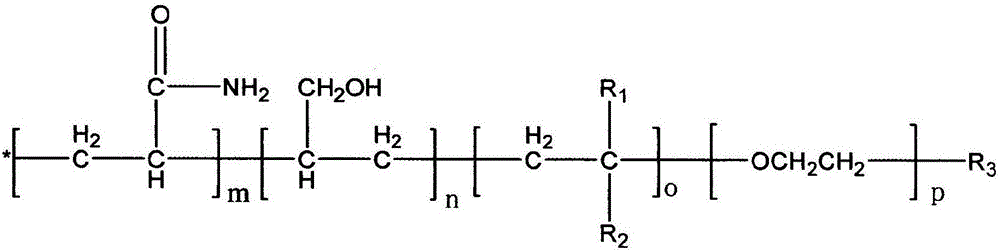

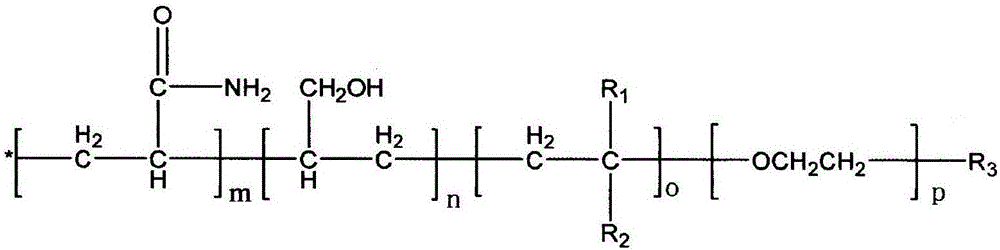

[0022] The molecular structure ge...

Embodiment 2

[0026] Embodiment 2: The wet-mixed mortar admixture of the present invention that can improve the early strength of mortar is composed of material A and material B. Wherein: the A material is made of the following components and weight (mass) ratio of raw materials: multifunctional water retention agent 320g, shrinkage reducing agent (polyethylene glycol, molecular weight 8000) 20g, Brunei glue 5g, 655g of water. The weight sum of each component in the above-mentioned A material is 1000g. The B material is made of the following components and weight (mass) ratio of raw materials: sugar retarder (sodium gluconate) 200g, organophosphorus retarder 200g (wherein hydroxyethylidene diphosphine acid 150g, aminotrimethylene phosphonic acid 50g), air-entraining agent 30g (wherein fatty alcohol polyoxyethylene ether sodium sulfate 10g, triterpene saponin 20g), water 570g. The weight sum of each component in the above-mentioned B material is 1000g. The general formula of the molecular...

Embodiment 3

[0028] Embodiment 3: The wet-mixed mortar admixture of the present invention that can improve the early strength of mortar is composed of material A and material B. Wherein: the A material is made of the following components and weight (mass) ratio of raw materials: multifunctional water retention agent 300g, shrinkage reducing agent (polyethylene glycol, molecular weight 4000) 15g, Brunei glue 1g, 684g of water. The weight sum of each component in the above-mentioned A material is 1000g. Described B material is to be made by the raw material of following composition and weight (mass) ratio: carbohydrate retarder 250g (sodium gluconate 100g, citric acid 150g), organophosphorus retarder (amino trimethyl Forked phosphonic acid) 250g, air-entraining agent 40g (wherein fatty alcohol polyoxyethylene ether sodium sulfate 15g, rosin thermal polymer 25g), water 460g. The weight sum of each component in the above-mentioned B material is 1000g. The general formula of the molecular st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com