A kind of preparation method of diethyl malonate

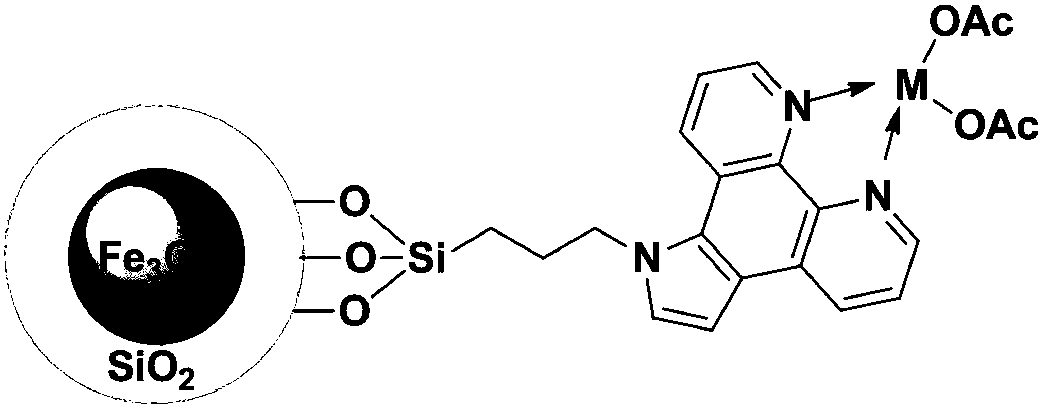

A technology of diethyl malonate and ethyl chloroacetate, applied in the field of chemistry, can solve the problems of difficult recycling of catalysts, long reaction time, equipment corrosion, etc., and achieves green and efficient reaction system, convenient recovery and reuse, and reaction conditions. mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

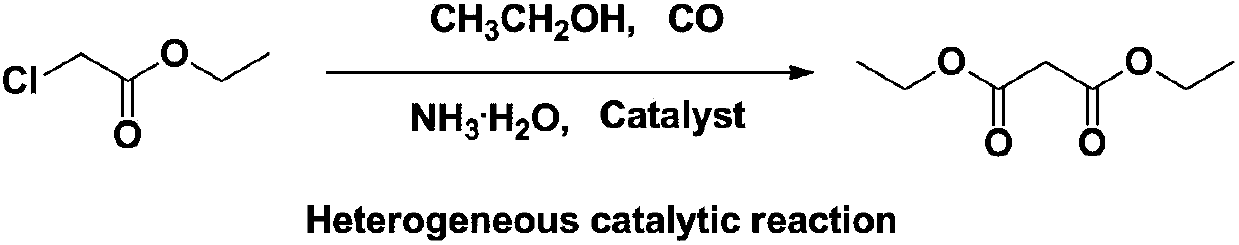

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] In a stainless steel autoclave, add ethyl chloroacetate (1mol), magnetic silica gel immobilized cobalt metal complex acetate (5g), ammonia (1.1mol), ethanol (2mol), mix well, replace the air in the kettle with carbon monoxide 4 times, then filled with carbon monoxide to maintain the pressure at 1.0 MPa, heated to 60° C., stirred and reacted for 2 hours. The product was separated by cooling, filtered, and the catalyst was recovered. The filtrate was rectified to obtain the product diethyl malonate with a yield of 82%. GC-MS analysis results showed that the purity of diethyl malonate was 96.8%.

Embodiment 2

[0023] In a stainless steel autoclave, add ethyl chloroacetate (1mol), magnetic silica gel immobilized cadmium metal complex acetate (7g), ammonia water (1.2mol), ethanol (2mol), mix well, replace the air in the kettle with carbon monoxide 4 times, then filled with carbon monoxide to maintain the pressure at 1.0 MPa, heated to 55° C., stirred and reacted for 2 hours. The product is separated by cooling and filtration, and the catalyst is recovered. The filtrate is rectified to obtain the product diethyl malonate with a yield of 85%. GC-MS analysis results showed that the purity of diethyl malonate was 96.7%.

Embodiment 3

[0025] In a stainless steel autoclave, add ethyl chloroacetate (1mol), magnetic silica gel immobilized zinc metal complex acetate (9g), ammonia (1.3mol), ethanol (3mol), mix well, replace the air in the kettle with carbon monoxide 4 times, then filled with carbon monoxide to maintain the pressure at 1.5MPa, heated to 70°C, and stirred for 5 hours. The product was separated by cooling, filtered, and the catalyst was recovered. The filtrate was rectified to obtain the product diethyl malonate with a yield of 79%. GC-MS analysis results showed that the purity of diethyl malonate was 95.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com