Surface-absorbing sugar-containing polymer and method for producing the same

A surface adsorption and polymer technology, applied in the field of sugar-containing polymers, can solve the problems that the surface adsorption function of sugar-containing polymers needs to be improved, and achieve the effects of good surface modification universality, easy operation, and cost-saving production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Weigh 0.2g of 2-(methacrylamido) glucopyranose, 36mg of dopamine methacrylamide, 0.5mg of copper powder, 1.9mg of isobutyronitrile dithionaphthoate and 0.3μL of α- Ethyl bromoisobutyrate was dissolved in 1 mL of dimethyl sulfoxide, and reacted for 8 hours at 25°C under room temperature and oxygen-free conditions in one pot, then methanol was used as the precipitant, and the product was slowly added dropwise to 200 mL of precipitant methanol to make it Agglomerate to obtain a white precipitate, centrifuge, dry, and weigh.

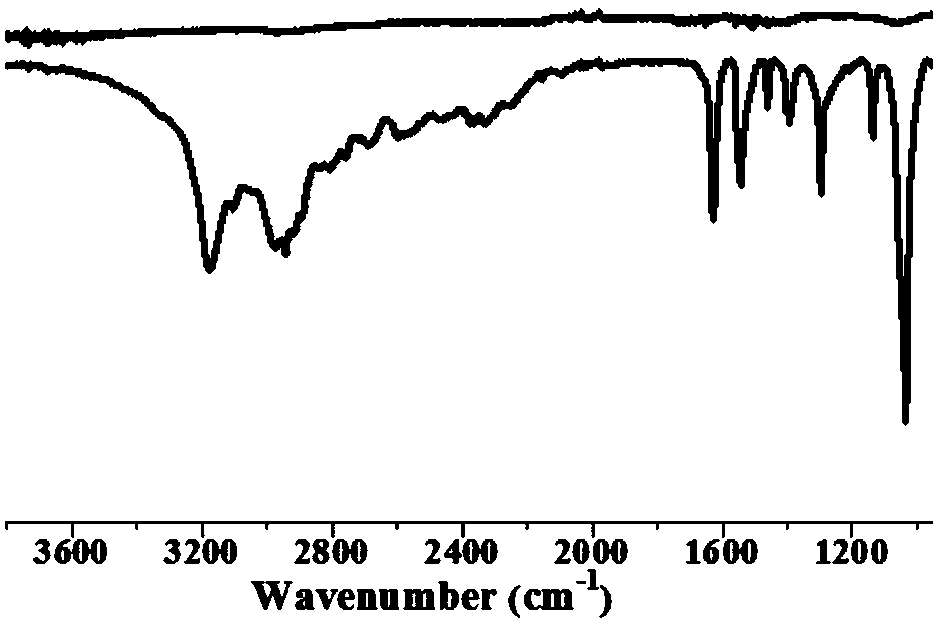

[0033] The structural formula of the prepared sugar-containing polymer PDMA-MAG with surface adsorption is as follows:

[0034]

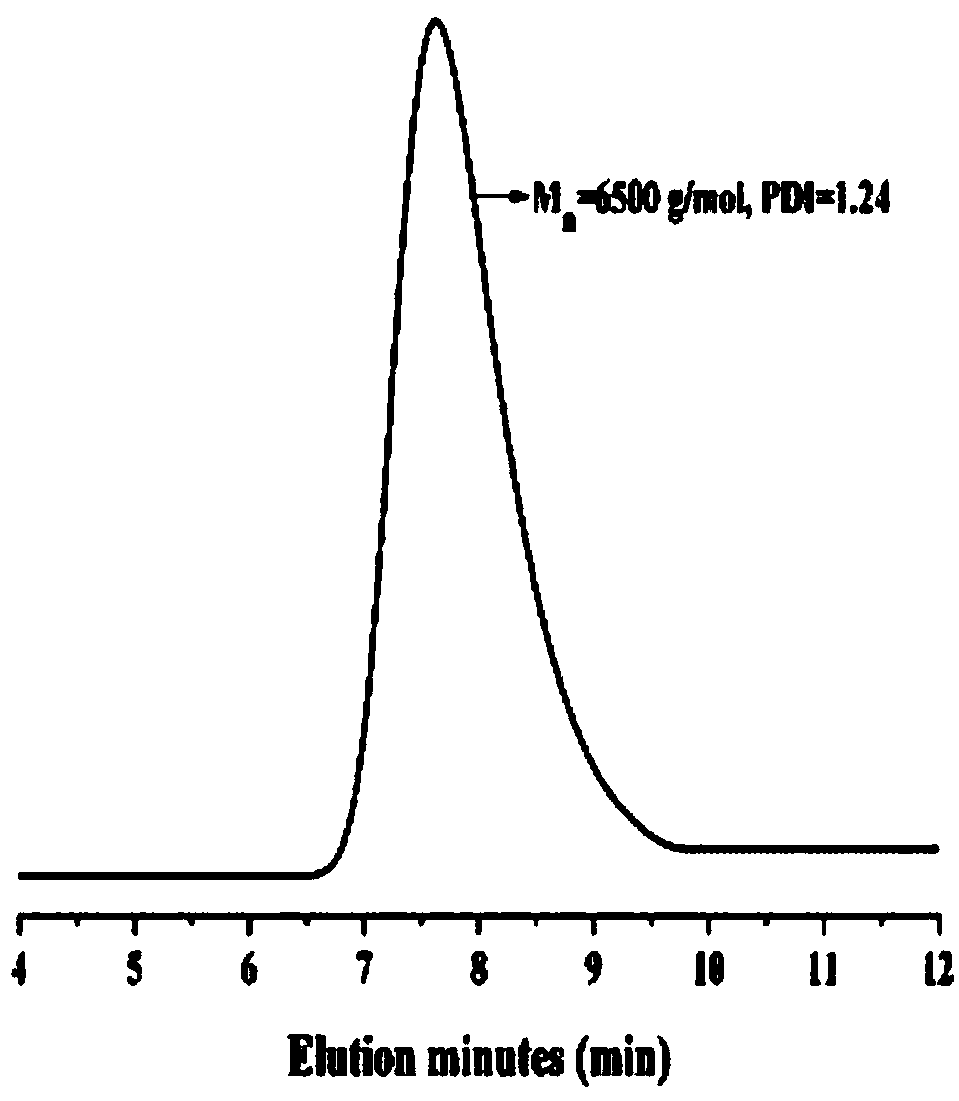

[0035] Among them, n:b=1:5, the molecular weight is 6500, and the molecular weight distribution is about 1.2, such as figure 1 Shown.

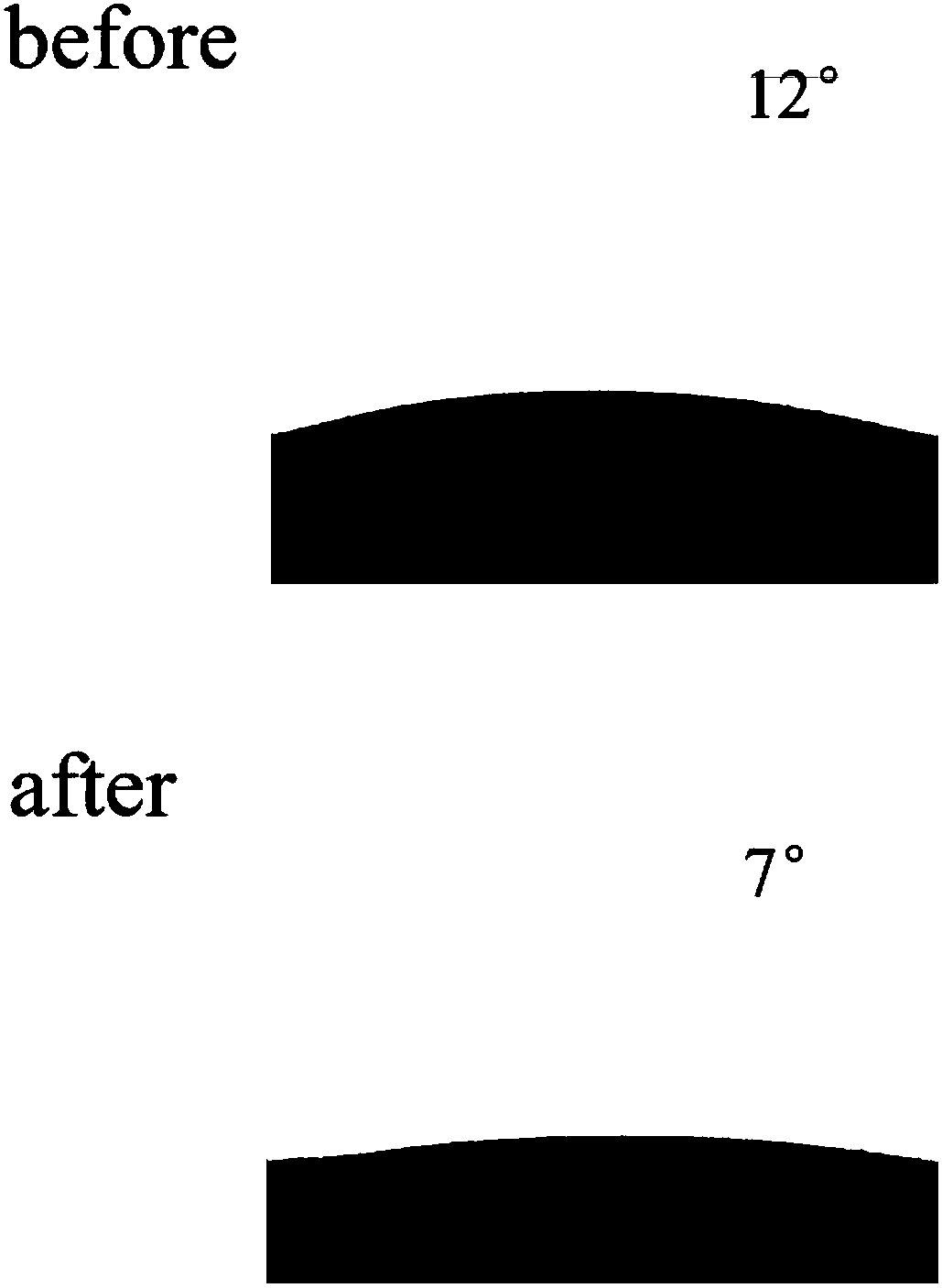

[0036] After mixing 50 mL, 0.1 mol / L tris solution with 22.9 mL, 0.1 mol / L hydrochloric acid, add water to dilute to 100 mL, adjust the pH of the mixed solution to 8.2, and prepare a Tris-Hcl sol...

Embodiment 2

[0040] Weigh 0.5 g of 2-(methacrylamido) galactopyranose, 56 mg of dopamine methacrylamide, 2 mg (excess) copper wire, 0.9 mg of azobisisobutyronitrile and 6.25 mg of 4-cyano- 4-(Phenylthioformylthio)pentanoic acid was dissolved in 1mL of dimethyl sulfoxide, reacted in one-pot reaction at 25℃, room temperature and anaerobic conditions for 8h, and then coagulated in 200ml methanol to obtain a white precipitate , Centrifugation, drying, weighing.

[0041] After mixing 50ml, 0.1mol / L tris solution and 22.9ml, 0.1mol / L hydrochloric acid, add water to dilute to 100mL, adjust the pH of the mixed solution to 8.2, and prepare a Tris-HCl solution.

[0042] Take 0.2 g of the sugar-containing polymer PDMA-MAG with surface activity and dissolve it in 10 mL of the prepared Tris-HCl solution to obtain a mixed solution. Place the silicon wafer in a petri dish, and add the above-mentioned mixed liquid dropwise to the silicon wafer. Immerse, put in a cool place at room temperature, wash the surfac...

Embodiment 3

[0044] Weigh 0.25g of 2-(methacrylamido) glucopyranose mannose, 44.7mg dopamine methacrylamide, 1mg iron powder and 2.2mg copper bromide powder composition, 1.2uL 2-bromopropionic acid The methyl ester and 4.2 mg of 4-cyano-4-(phenylthioformylthio)pentanoic acid N-succinimidyl ester were dissolved in 1 mL of dimethyl sulfoxide, and there was no oxygen at room temperature at 25°C. The conditions were one-pot reaction for 8 hours, and then coagulation in methanol to obtain a white precipitate, which was centrifuged, dried, and weighed.

[0045] After mixing 50ml, 0.1mol / L tris solution and 22.9ml 0.1mol / L hydrochloric acid, add water to dilute to 100ml, adjust the pH of the mixed solution to 8.2, and make up a Tris-HCl solution.

[0046] Take 0.2 g of the sugar-containing polymer PDMA-MAG with surface activity and dissolve it in the prepared Tris-HCl solution to obtain a mixed solution, place the polystyrene sheet in a petri dish, and add the above mixed solution dropwise to the poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com