Conductive silk fibroin material and preparation method thereof

A technology of silk fibroin and conductive filaments, which is applied in medical science, prosthesis, tissue regeneration, etc. It can solve the problems of difficult polymerization and modification, achieve uniform conductive layer structure, firm connection, and promote cell regeneration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A preparation method of a conductive silk fibroin material, firstly degumming silkworm cocoons by boiling a sodium carbonate solution with a mass fraction of 0.5%, dissolving them in a 9.0M lithium bromide solution, and concentrating them to a concentration of 15wt%; Then, after the product is obtained by tape casting, it is soaked in 75% ethanol aqueous solution to promote its secondary structure to β-sheet transformation so as to be insoluble in water, that is, to obtain the silk fibroin material through insolubilization treatment;

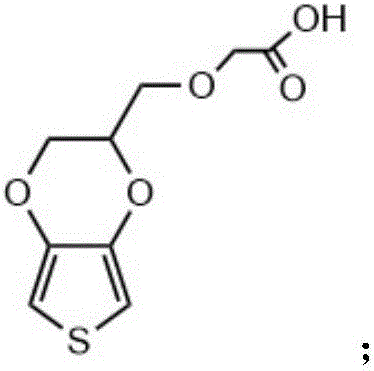

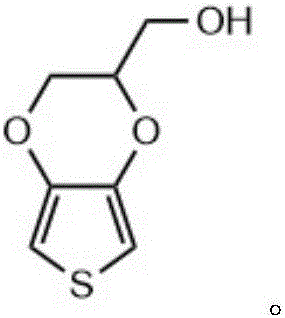

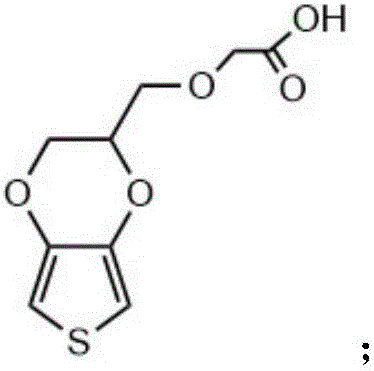

[0044] Then add it to the aqueous solution of 2-((2,3-dihydrothieno[3,4-b][1,4]dioxin-2-yl)methoxy)acetic acid with a concentration of 20mmol / L Sodium dodecyl sulfate (SDS) with a chemical equivalent of 3 / 10, 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (EDC) with the same chemical equivalent N-hydroxysuccinimide (NHS), using phosphate buffer solution (pH value is 7.4, the concentration of potassium dihydrogen phosphate is ...

Embodiment 2

[0050] A preparation method of a conductive silk fibroin material, firstly degumming silkworm cocoons by boiling a sodium carbonate solution with a mass fraction of 0.5%, dissolving them in a 9.0M lithium bromide solution, and concentrating them to a concentration of 16wt%; then molded to obtain the product, and then soaked in 76% ethanol aqueous solution to promote its secondary structure to β-sheet transformation so that it is insoluble in water, that is, the silk fibroin block material that has been insolubilized ;

[0051] Then add it to the aqueous solution of 2-((2,3-dihydrothieno[3,4-b][1,4]dioxin-2-yl)methoxy)acetic acid at a concentration of 21mmol / L Sodium dodecyl sulfate (SDS) with a chemical equivalent of 3 / 10, 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (EDC) with the same chemical equivalent N-hydroxysuccinimide (NHS), using phosphate buffer solution (pH value is 7.4, the concentration of potassium dihydrogen phosphate is 0.038M, the concentratio...

Embodiment 3

[0057] A preparation method of a conductive silk fibroin material, firstly degumming silkworm cocoons by boiling a sodium carbonate solution with a mass fraction of 0.5%, dissolving them in a 9.0M lithium bromide solution, and concentrating them to a concentration of 18wt%; adding glycerol with a mass ratio of 6:100 to silkworm cocoons for small molecule plasticization; and then forming the product according to the molding method, and then soaking in 82% ethanol aqueous solution to promote its secondary structure to β folding Transformation so that it is insoluble in water, that is, the insoluble silk fibroin bulk material is obtained;

[0058] Then it was added to an aqueous solution of 2-((2,3-dihydrothieno[3,4-b][1,4]dioxin-2-yl)methoxy)acetic acid at a concentration of 26mmol / L. Sodium dodecyl sulfate (SDS) with a chemical equivalent of 4 / 10, 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (EDC) with the same chemical equivalent N-hydroxysuccinimide (NHS), usi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistance | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com