3D porous electrode preparation method and use of 3D porous electrode in electrochemical hydrogen evolution

A porous electrode, 3D technology, applied in the field of energy storage, can solve the problems of insufficient space for mass transfer, limited pore structure, weak interaction, etc., and achieve the effect of small batch difference, short time and excellent activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] The carbon cloth was pickled with 0.5M sulfuric acid and washed with ethanol alcohol.

[0090] The treated carbon cloth was repeatedly impregnated three times with cobalt nitrate salt solution (0.1 g / ml). In the presence of melamine (8.2 g), undergo the following pyrolysis process at 600° C. for 1 h and at 700° C. for 3.0 h.

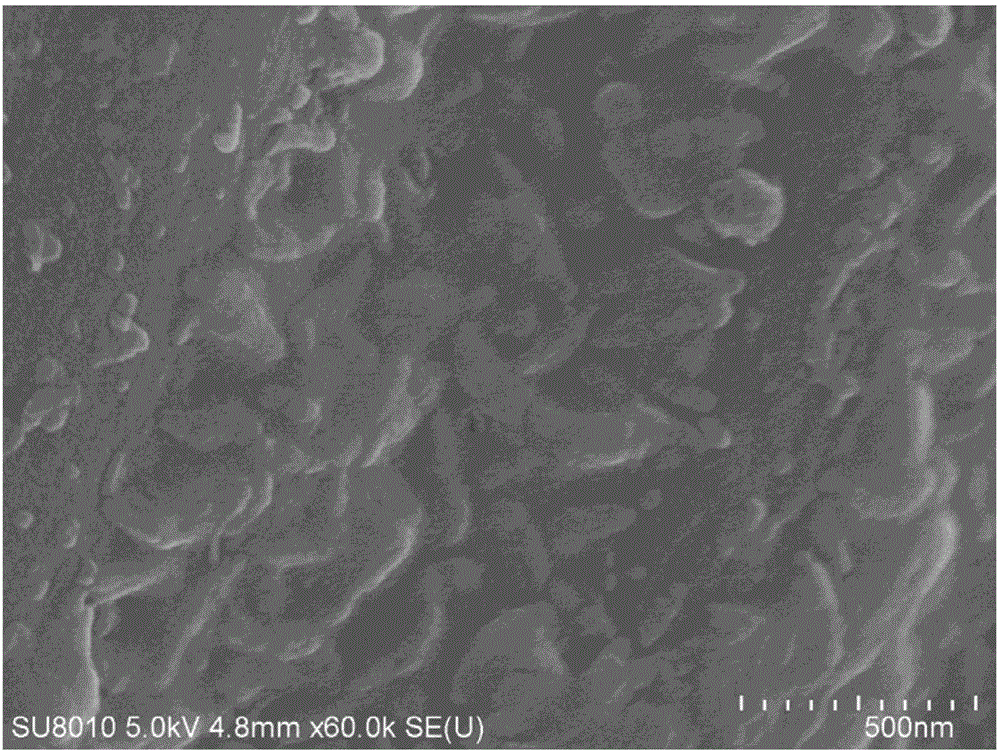

[0091] The scanning electron microscope picture of the 3D porous electrode prepared in this embodiment is shown in Figure 5a , as can be seen from the electron microscope images, the material prepared under this condition has a special structure of carbon tubes grown on the surface of carbon fibers in a large range, and the carbon tubes are short and evenly distributed. Figure 5b It is a transmission electron microscope picture of a single carbon tube obtained after carbon cloth is ultrasonically treated. It can be seen that the position of the end of the carbon tube peeled off by ultrasonic is wrapped with a metal, and the diameter of the carb...

Embodiment 2

[0093] The carbon cloth was pickled with 0.5M sulfuric acid and washed with ethanol alcohol.

[0094] The treated carbon cloth was repeatedly impregnated 6 times with cobalt acetate solution (0.8 g / ml). In the presence of melamine (5.5 g), undergo the following pyrolysis process at 600° C. for 1 h and at 900° C. for 1.5 h.

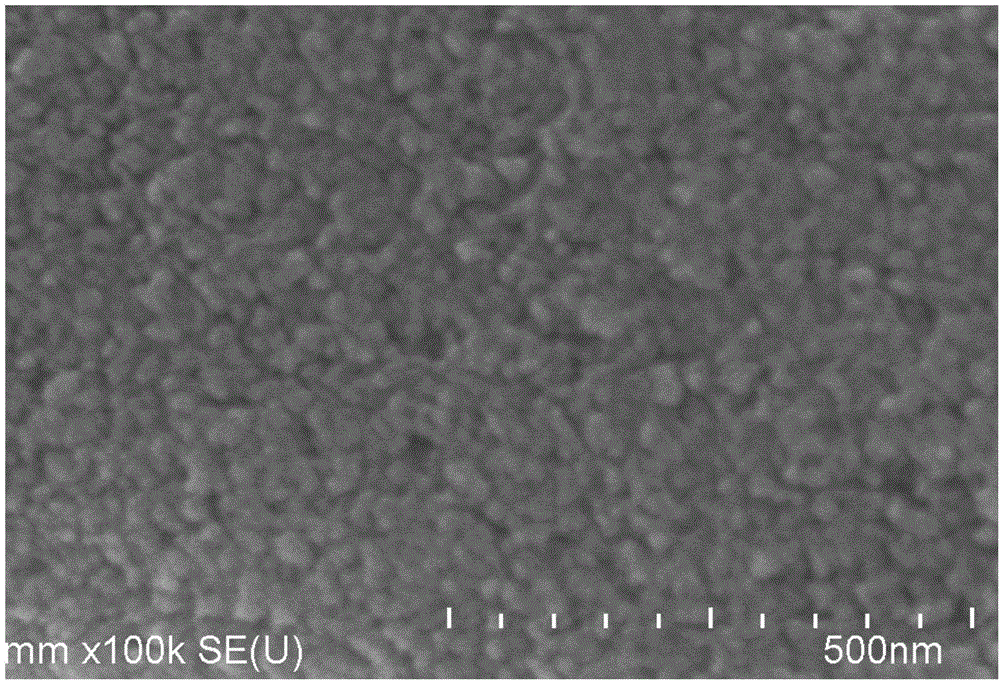

[0095] The scanning electron microscope picture of the 3D porous electrode prepared in this embodiment is shown in Figure 6 , as can be seen from the electron microscope images, the material prepared under this condition has a special structure of carbon tubes grown on the surface of carbon fibers in a large range, and the carbon tubes are short and evenly distributed.

Embodiment 3

[0097] The carbon cloth was pickled with 0.5M sulfuric acid and washed with ethanol alcohol.

[0098] The treated carbon cloth was repeatedly impregnated 3 times with cobalt sulfate solution (0.7 g / ml). In the presence of melamine (5 g), undergo the following pyrolysis process at 600° C. for 1 h and at 900° C. for 3.5 h.

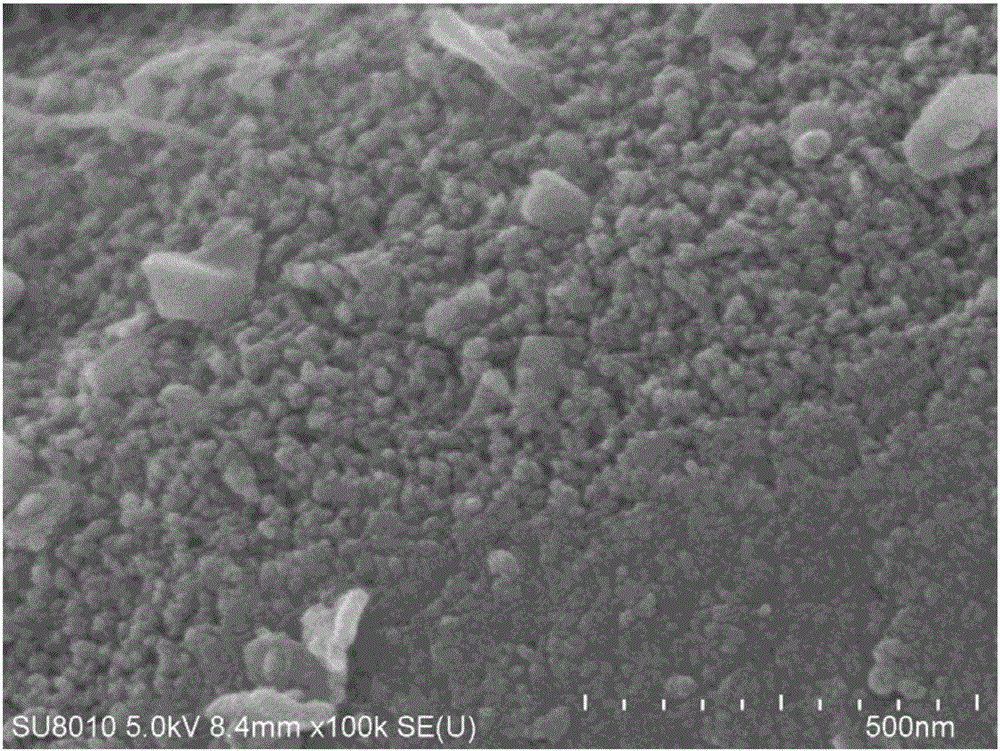

[0099] The scanning electron microscope picture of the 3D porous electrode prepared in this embodiment is shown in Figure 7 , as can be seen from the electron microscope images, the material prepared under this condition has a special structure of carbon tubes grown on the surface of carbon fibers in a large range, and the carbon tubes are short and evenly distributed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com