Tubular composite shielded and insulated bus and making process thereof

A composite shielding and insulating busbar technology, applied in the direction of insulating conductors, insulating cables, insulating conductors/cables, etc., can solve problems such as the incompatibility of humidity and temperature, the decrease of electrical insulation performance of tube and busbar, and the increase of skin effect coefficient, etc. Achieve the effect of improving power supply reliability, good heat dissipation conditions, and low skin effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

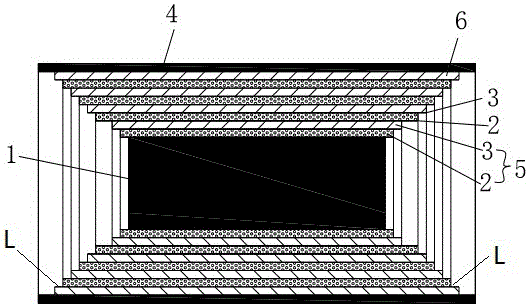

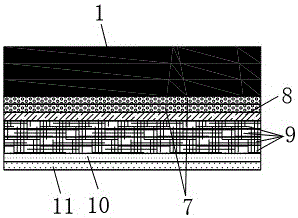

[0086] The structure and manufacturing process of the 10KV composite shielded insulated copper tube busbar are as follows:

[0087] Step 1: Leave 20cm at both ends of the conductor, and then wrap 2 layers of PTFE oriented film tightly on the surface of the conductor.

[0088] Step 2: Tightly wrap a layer of aluminum foil on the outside of the PTFE oriented film.

[0089] Step 3: Wrap 4 layers of polytetrafluoroethylene around the aluminum foil, and apply silicone oil evenly

[0090] Step 4: Install a transparent heat-shrinkable sleeve containing polytetrafluoroethylene on the outer surface of the polytetrafluoroethylene oriented film. Steps 1, 2, 3, and 4 can be regarded as the first insulation shielding layer, and then leave 5cm at both ends of each insulation shielding layer to make the second, third, and fourth insulation shielding layers, a total of four For the insulating shielding layer, heat shrink two layers of insulating sheath outside the fourth insulating shieldin...

Embodiment 2

[0092] The structure and manufacturing process of the 35KV tubular composite shielding insulating tube busbar are as follows:

[0093] A. Step 1, leave 20cm at both ends of the conductor, and then tightly wrap two layers of PTFE oriented film on the surface of the conductor.

[0094] B. Step 2: Tightly wrap a layer of aluminum foil outside the PTFE oriented film.

[0095] C. Step 3: Wrap 4 layers of polytetrafluoroethylene around the aluminum foil and apply silicone oil evenly

[0096] D. Step 4: Set a transparent heat-shrinkable sleeve containing polytetrafluoroethylene on the outer surface of the polytetrafluoroethylene oriented film. E. Steps 1, 2, 3, and 4 can be regarded as the first insulating shielding layer, and then leave 5cm at both ends of each insulating shielding layer for the second, third, fourth, fifth, sixth, and second Seventh, the production of the eighth insulation shielding layer, a total of eight insulation shielding layers, heat shrink two layers of in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com