A high-dielectric gate dielectric material for flexible low-voltage driving organic thin film transistors and its preparation method and application

An organic thin film, low-voltage driven technology, applied in the field of organic electronics, can solve the problems of reducing the carrier mobility of the device, high annealing temperature of the dielectric layer, and high turn-on voltage of the device, and achieves large switching ratio, high mobility, The effect of a small subthreshold slope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] This embodiment provides a method for preparing a flexible low-voltage drive organic thin film transistor, including the following steps:

[0049] 1) Depositing the bottom gate electrode on the cleaned substrate: specifically including the following steps:

[0050] 1a) Select a flexible PET substrate and cut it into a square block of 1.5cm×1.5cm;

[0051] 1b) The substrate was ultrasonically cleaned with acetone, isopropanol, deionized water, and ethanol in sequence, then dried in an oven, and then subjected to UV / O 3 After activation, save it for later use;

[0052] 1c) A 40 nm thick Au bottom-gate electrode was deposited on a cleaned PET substrate by thermal evaporation; the deposition was carried out under high vacuum with an air pressure of 6 × 10 -4 Pa, the deposition rate is 0.02nm / s;

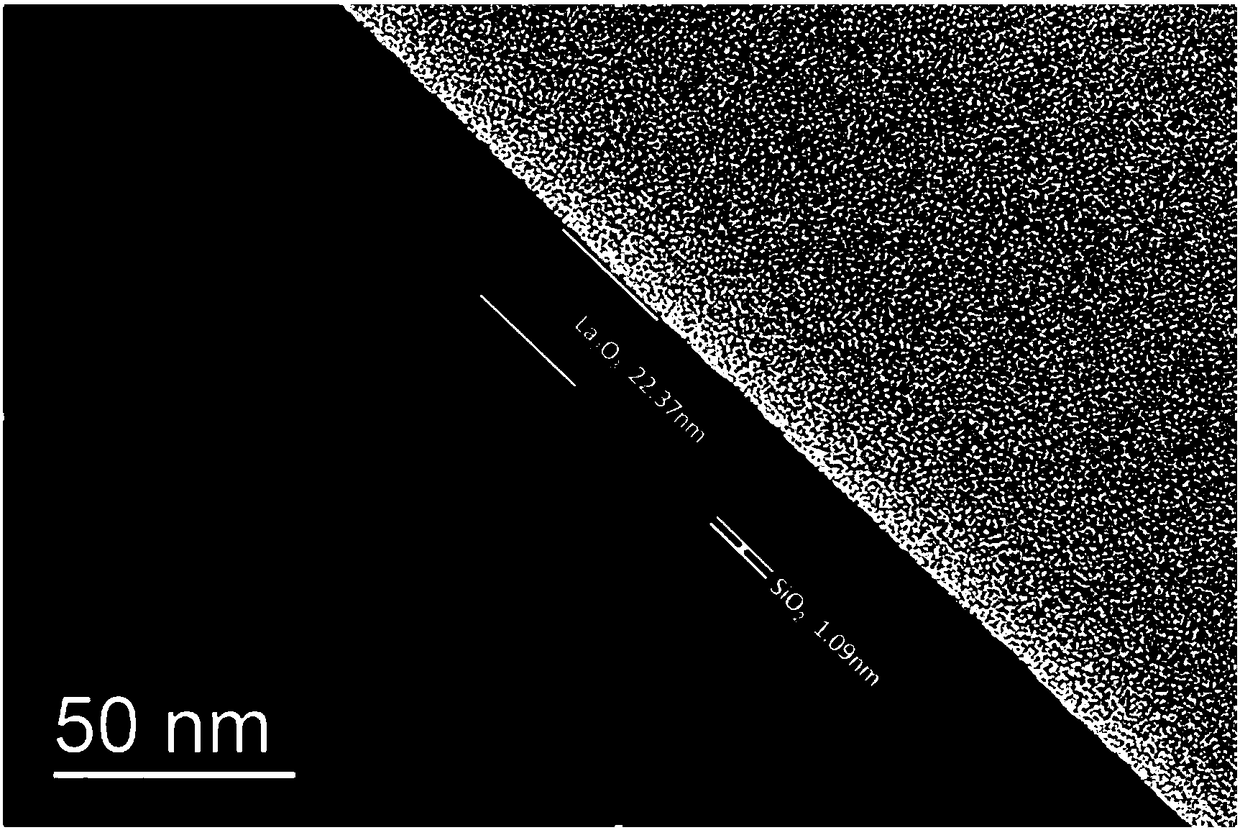

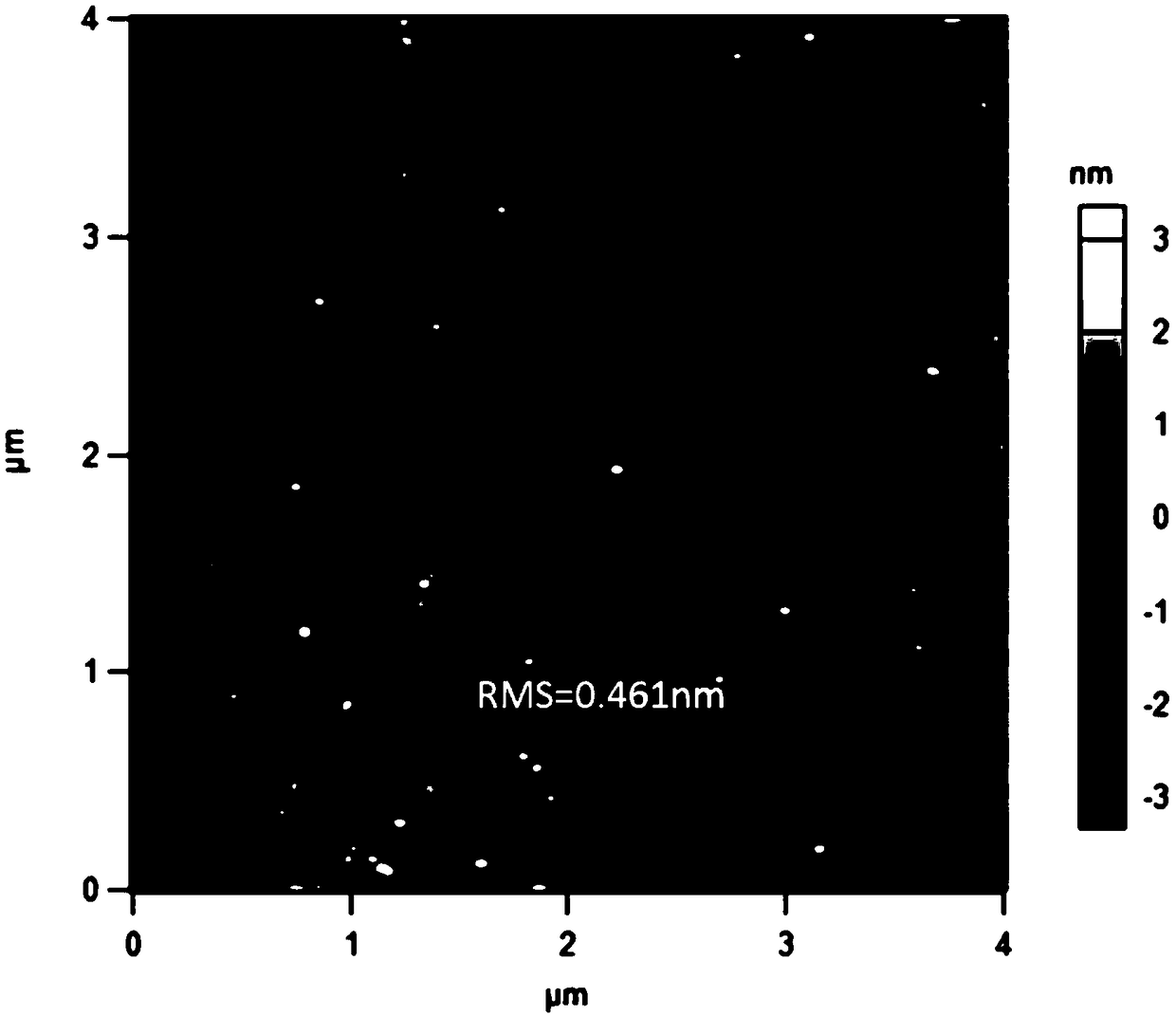

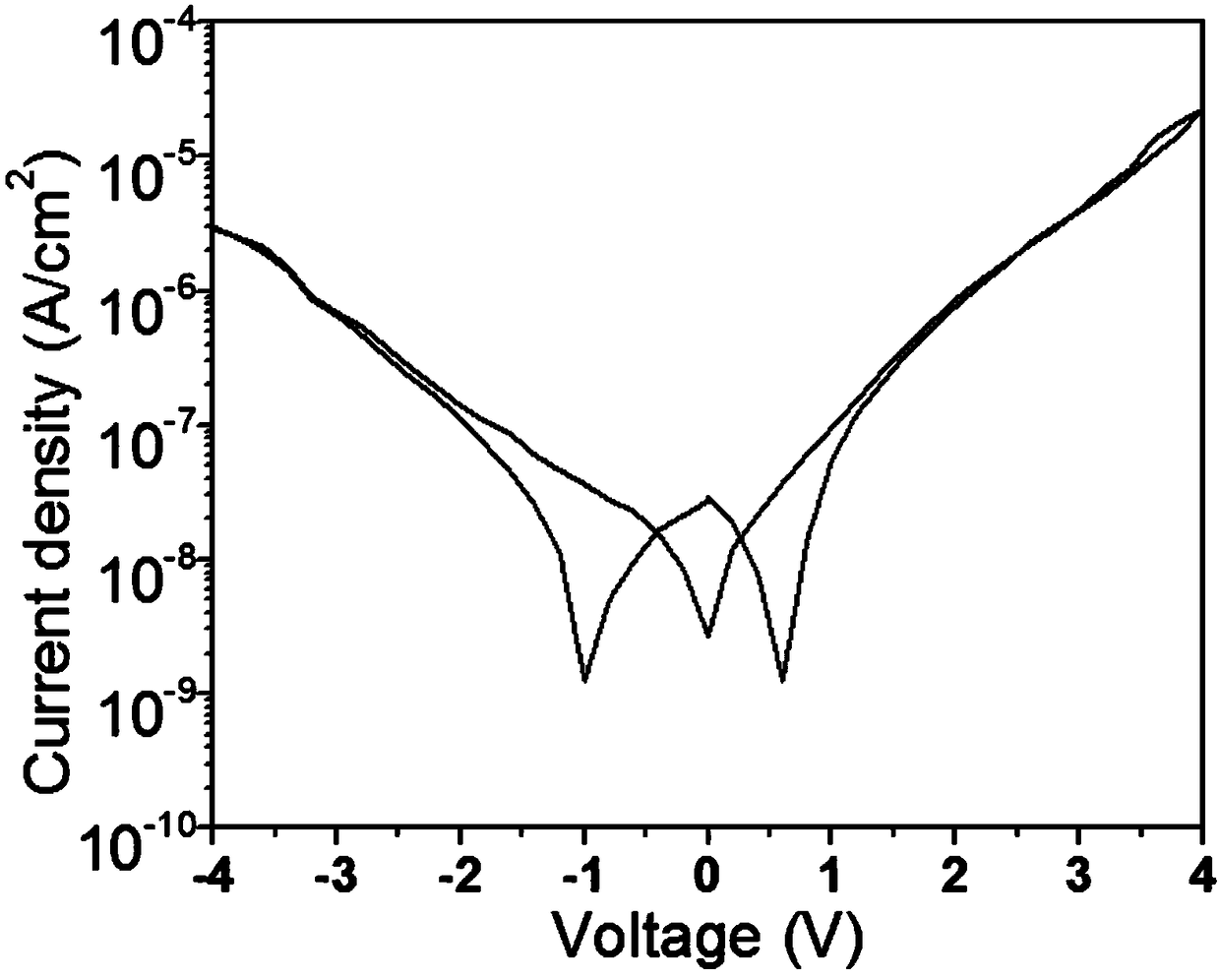

[0053] 2) Preparation of lanthanum oxide precursor solution: use lanthanum acetylacetonate as the solute, N,N-dimethylformamide (DMF) as the solvent, prepare a solution with a m...

Embodiment 2

[0061] This embodiment provides a method for preparing a flexible low-voltage drive organic thin film transistor, including the following steps:

[0062] 1) Depositing the bottom gate electrode on the cleaned substrate: specifically including the following steps:

[0063] 1a) Select a flexible PET substrate and cut it into a square block of 1.5cm×1.5cm;

[0064] 1b) The substrate was ultrasonically cleaned with acetone, isopropanol, deionized water, and ethanol in sequence, then dried in an oven, and then subjected to UV / O 3 After activation, save it for later use;

[0065] 1c) A 40 nm thick Au bottom-gate electrode was deposited on a cleaned PET substrate by thermal evaporation; the deposition was carried out under high vacuum with an air pressure of 6 × 10 -4 Pa, the deposition rate is 0.01nm / s;

[0066] 2) Preparation of lanthanum oxide precursor solution: use lanthanum acetylacetonate as the solute, N,N-dimethylformamide (DMF) as the solvent, prepare a solution with a m...

Embodiment 3

[0074] This embodiment provides a method for preparing a flexible low-voltage drive organic thin film transistor, including the following steps:

[0075] 1) Depositing the bottom gate electrode on the cleaned substrate: specifically including the following steps:

[0076] 1a) Select a flexible PET substrate and cut it into a square block of 1.5cm×1.5cm;

[0077] 1b) The substrate was ultrasonically cleaned with acetone, isopropanol, deionized water, and ethanol in sequence, then dried in an oven, and then subjected to UV / O 3 After activation, save it for later use;

[0078] 1c) A 40 nm thick Au bottom-gate electrode was deposited on a cleaned PET substrate by thermal evaporation; the deposition was carried out under high vacuum with an air pressure of 6 × 10 -4 Pa, the deposition rate is 0.03nm / s;

[0079] 2) Preparation of lanthanum oxide precursor solution: use lanthanum acetylacetonate as the solute, N,N-dimethylformamide (DMF) as the solvent, prepare a solution with a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com