PLGA three-dimensional nerve conduit and preparation method thereof

A technology of nerve conduit and PLGA, which is applied in the fields of pharmaceutical formulation, fiber treatment, coating, etc., can solve the problems of unfavorable cell penetration and three-dimensional growth, small pore size, and low porosity of nano-scale fibers, so as to promote cell adhesion and axis The effects of sudden growth, easy degradation, and excellent biomechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

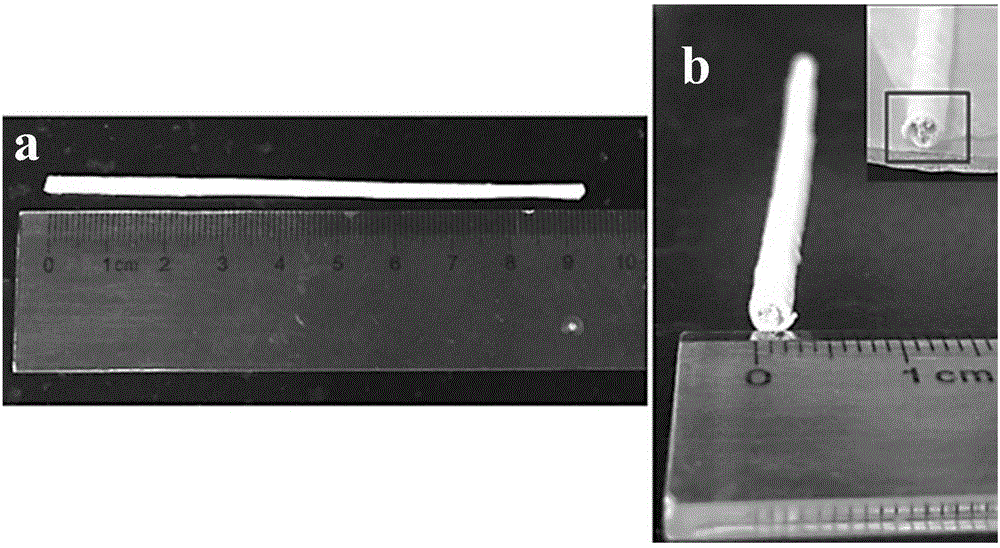

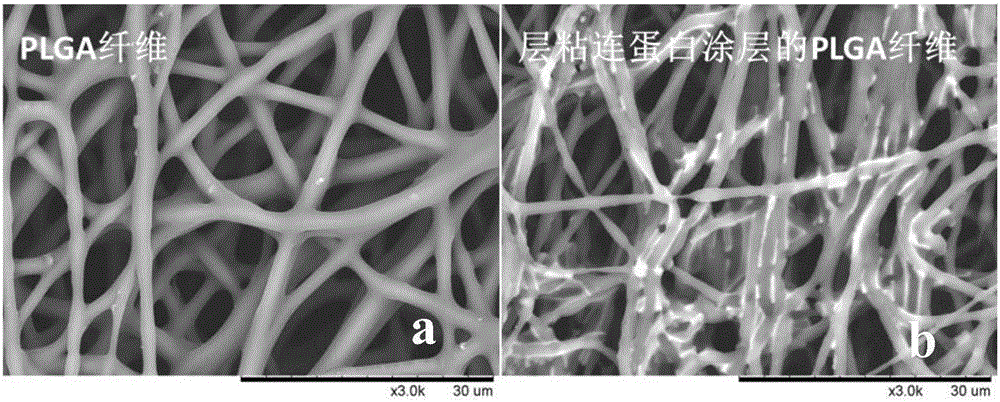

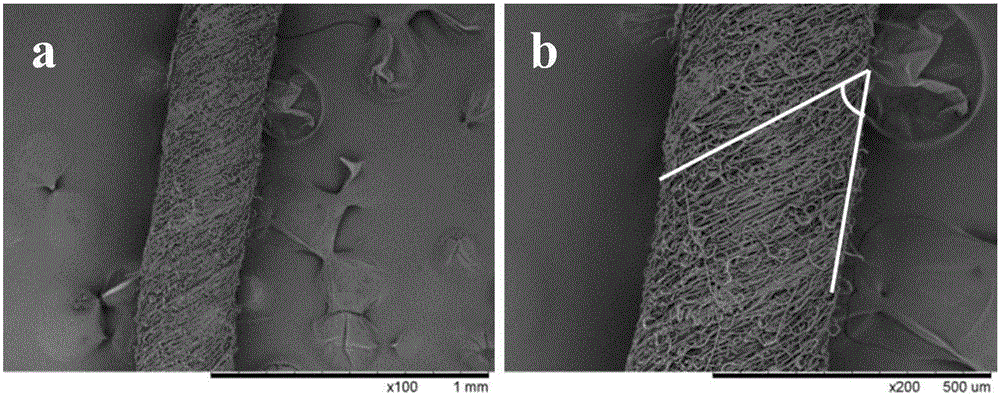

Embodiment 1

[0036]Weigh 1.5 g of PLGA with an electronic balance and dissolve it in 10 mL of hexafluoroisopropanol, stir overnight until completely dissolved to obtain a PLGA spinning solution; use a custom-made double-nozzle spinning equipment to prepare PLGA yarns with uniform diameters, spin The silk parameters are: the flow rate of the PLGA spinning solution of the double nozzles is 0.02mL / min and 0.032mL / min, the two ends are positive high voltage and negative high voltage +10kV and -10kV respectively, the distance between the two nozzles is 15cm, and the rotating horn The rotating speed 500rpm, the distance from the bottom end of the rotating horn to the yarn receiving device is 60cm, and the rotating speed of the yarn receiving device is 5rpm to obtain the PLGA yarn; the PLGA yarn is cut into a uniform length of 8cm, and a receiving rod with a diameter of 2mm is selected. Arrange 40 yarns axially on the receiving rod and fix them; use this as a rotating device to receive PLGA fibers...

Embodiment 2

[0038] Weigh 1.2 g of PLGA with an electronic balance and dissolve it in 10 mL of hexafluoroisopropanol, stir overnight until completely dissolved to obtain a PLGA spinning solution; use a custom-made double-nozzle spinning equipment to prepare PLGA yarns with uniform diameters, spin The silk parameters are: the flow rate of the PLGA spinning solution of the double nozzles is 0.02mL / min and 0.032mL / min, the two ends are positive high voltage and negative high voltage +10kV and -10kV respectively, the distance between the two nozzles is 15cm, and the rotating horn The rotating speed of 350rpm, the distance from the bottom end of the rotating horn to the yarn receiving device is 60cm, and the rotating speed of the yarn receiving device is 7rpm to obtain the PLGA yarn; the PLGA yarn is cut into a uniform length of 10cm, and a receiving rod with a diameter of 1mm is selected. Arrange 20 yarns axially on the receiving rod and fix them; use this as a rotating device to receive PLGA f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com