Weather-resistant freeze-thaw-resistant thermal insulation mortar and preparation method thereof

A thermal insulation mortar, freeze-thaw-resistant technology, applied in the field of building materials, can solve the problems of limited application scope, shortened service life, poor freeze-thaw resistance, etc., achieves good freeze-thaw resistance, improves bond strength and compressive strength, The effect of improving weather resistance and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

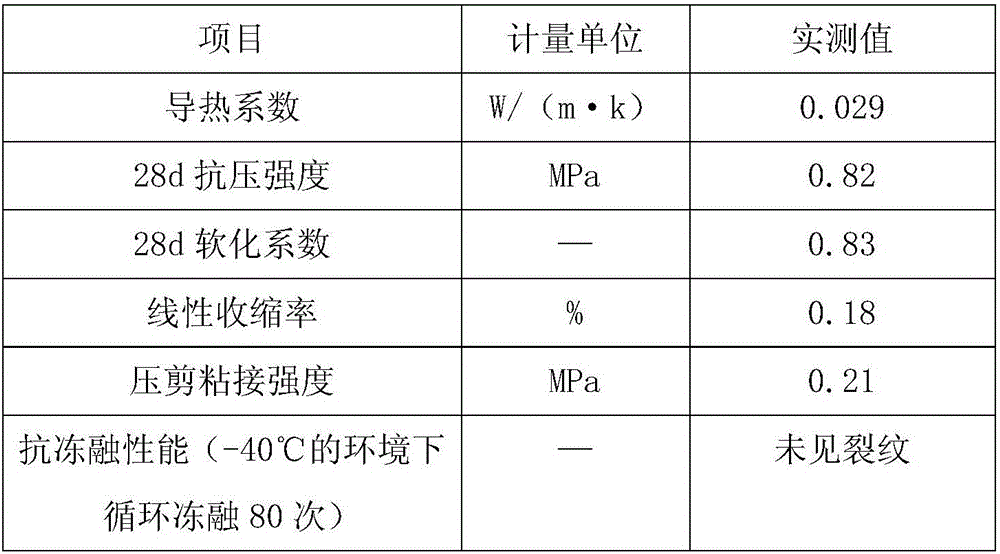

[0012] A weather-resistant freeze-thaw thermal insulation mortar, made of the following weight (kg) raw materials: polyaluminum chloride 15, phosphate cement 60, xonotlite 22, magnesite 7, fiber stone 16, silica fume powder 12 , Porous calcium silicate 11, sawdust 8, nano-titanium dioxide 10, halloysite 20, oil shale ash 12, double fly powder 10, sesame powder 6, lithium chloride 4.5, calcium nitrite 3, polyglutamic acid 8.

[0013] A method for preparing weather-resistant freeze-thaw thermal insulation mortar, including the following steps:

[0014] (1) Mix xonotlite, silica fume powder, oil shale ash, and halloysite evenly, put them in a pulverizer, smash, sieving, and then put them into a ball mill for wet ball milling for 1 hour, and the ball mill speed is 3500r / min , The ratio of water to material is 1:5, vacuum drying, sieving, and conveying the dried powder to the arc area of the plasma reaction furnace so that the powder is heated and melted. The working gas is compresse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com