Indirect formaldehyde screening and detection analysis method

An analysis method, formaldehyde technology, applied in the field of detection and analysis of formaldehyde in aqueous solution, can solve the problems of cumbersome operation steps and long time consumption, and achieve the effect of simple mechanism and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1: experimental procedure

[0043] The experimental steps of the present invention are as follows, and the conditions are all optimized results. The invention is based on the indirect detection and analysis method of formaldehyde, which is based on ammonia or ammonium ion quantitatively reacting with formaldehyde in aqueous solution to generate hexamethylenetetramine, and then directly adopts an electrospray tandem mass spectrometer to detect the hexamethylenetetramine. Ammonium carbonate ((NH 4 ) 2 CO 3 ) is the reaction reagent as an example to illustrate the experimental procedure for the detection of free formaldehyde in aqueous solution.

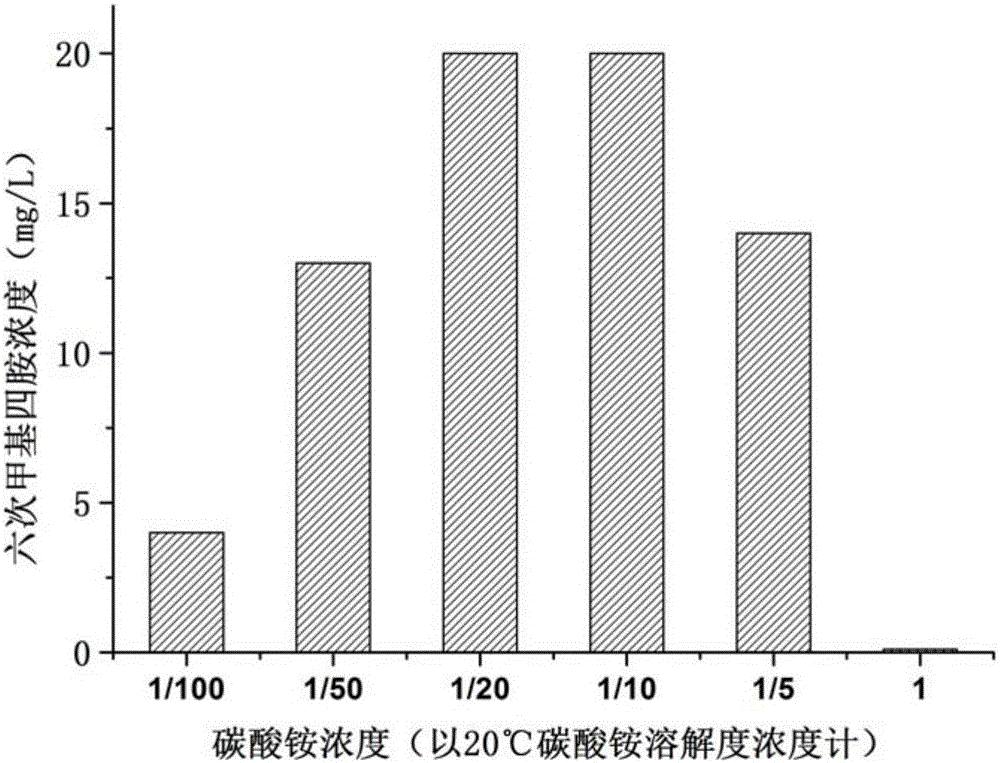

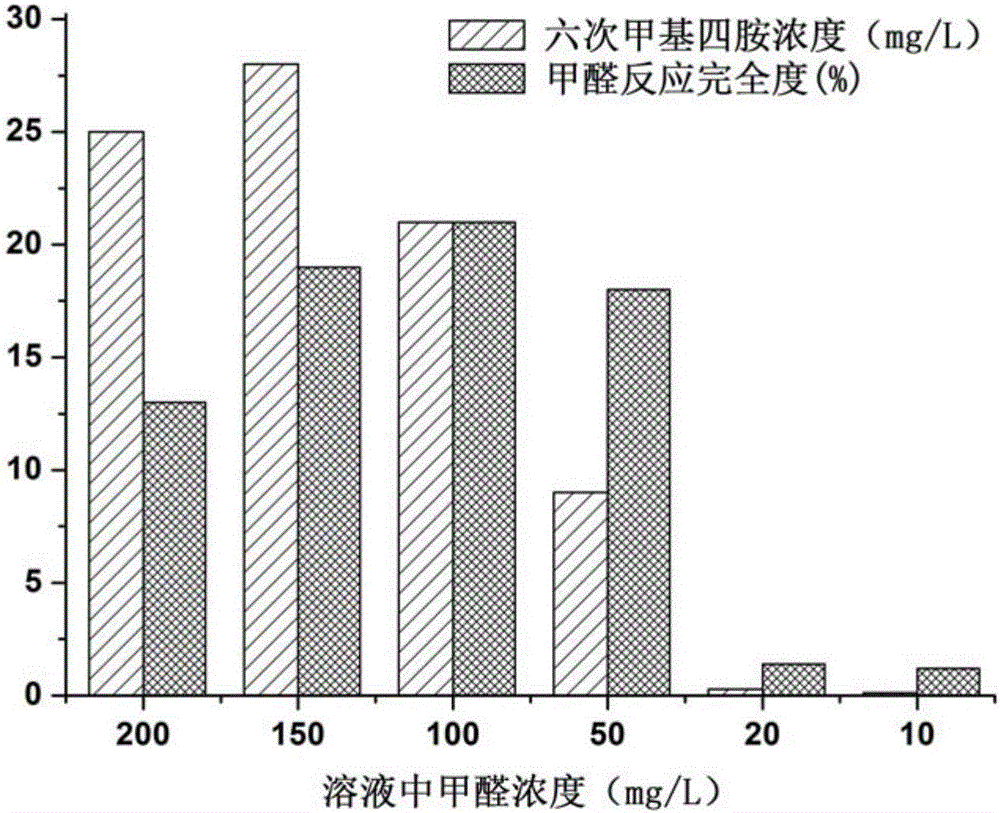

[0044] (1) The experimental steps for the reaction of ammonium root and formaldehyde are as follows: first, under the condition of 20°C, prepare a saturated ammonium carbonate solution (solubility in water at 20°C is 100g / 100mL) for use; then take 50 microliters of ammonium carbonate solution for use In 1 ml of fre...

Embodiment 2

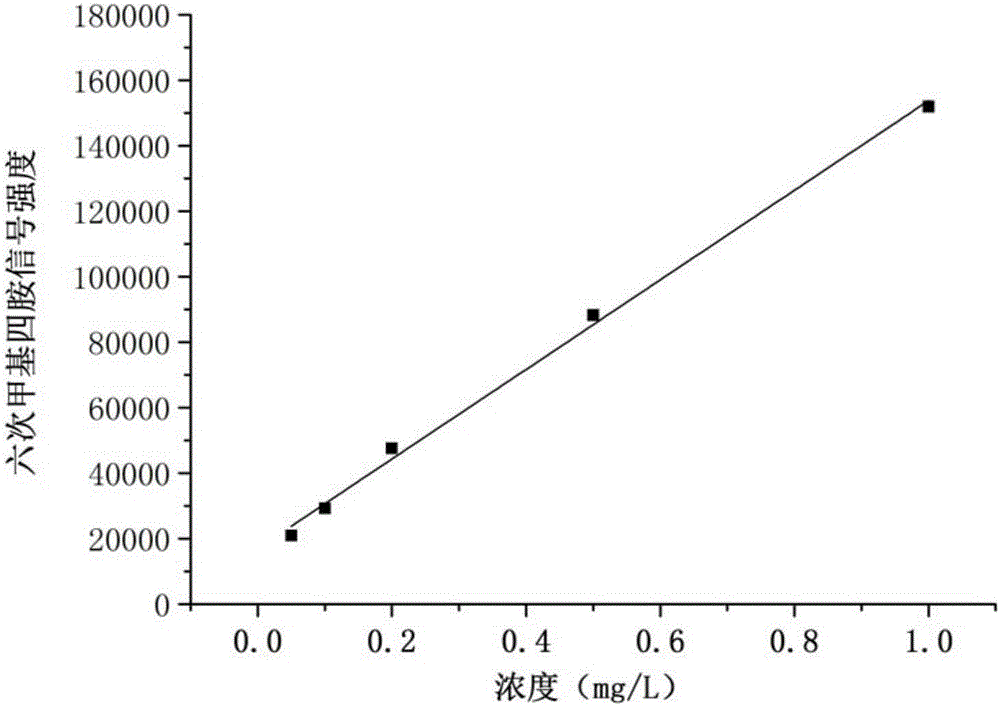

[0045] Embodiment 2: the establishment of standard curve:

[0046] Prepare hexamethylenetetramine aqueous solution, the reference concentrations are 0.01, 0.025, 0.05, 0.1, 0.5, 1.0 mg / L;

[0047] (1) The liquid chromatography condition in the liquid chromatography mass spectrometry is: C 18 Column, column diameter 2.1mm, column length 150mm; mobile phase methanol and water (80:20), isocratic elution; flow rate 0.4mL / min; hexamethylenetetramine retention time: 0.96min; Volume: 5 microliters;

[0048] (2) The analysis conditions of the electrospray tandem mass spectrometer in the liquid chromatography mass spectrometer are: MRM mode (multiple ion reaction mode), the parent ion is m / z 141, and the product ions are m / z 112, m / z 98 and m / z 85 (the total ion current chromatogram of the liquid chromatography electrospray tandem mass spectrometer of hexamethylenetetramine is shown in Figure 4 , a chromatographic peak with a retention time of 0.96min; the scanning mass spectrum o...

Embodiment 3

[0052] Example 3: Determination of free and hydrolyzable formaldehyde in textiles

[0053] Reference standard: GB / T 2912.1-2009

[0054] This example shows the case where the sample to be tested is a textile and all accessible parts of the textile sample are tested.

[0055] 1. Sample preparation

[0056] The samples were not conditioned, and the pre-conditioning may affect the formaldehyde content in the samples. The samples were sealed and stored before testing.

[0057] Take two samples from the sample, cut them into pieces, and weigh 1g, accurate to 10mg. If the formaldehyde content is too low, increase the sample size to 2.5 g to obtain satisfactory accuracy.

[0058] 2. Sample extraction and pretreatment

[0059] According to the requirements of GB / T 2912.1-2009, put each sample into a 250mL Erlenmeyer flask with a stopper, add 100mL of water, close the lid tightly, put it in a water bath with a temperature of (40±2)°C, shake (60±5) min, and then filtered into anot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com