Preparation method of porous carbon aerogel with super-high specific surface area

A technology of ultra-high specific surface area and carbon airgel, which is applied in the direction of electrical components, battery electrodes, non-aqueous electrolyte batteries, etc., to achieve good cycle stability, simple preparation process, and high specific capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

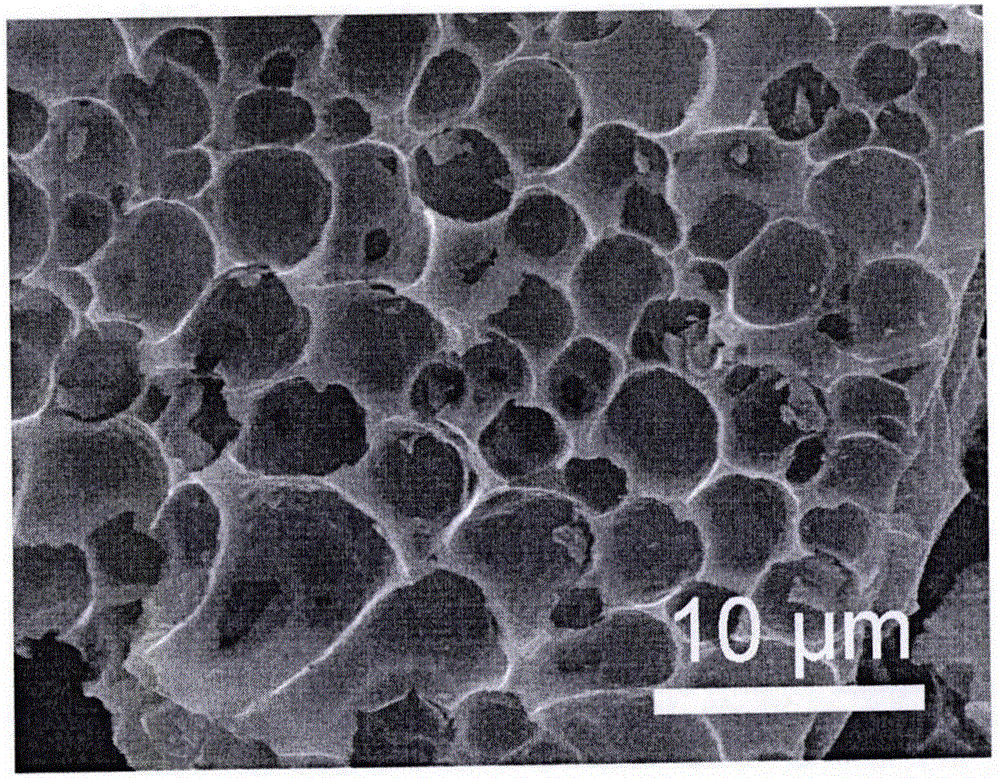

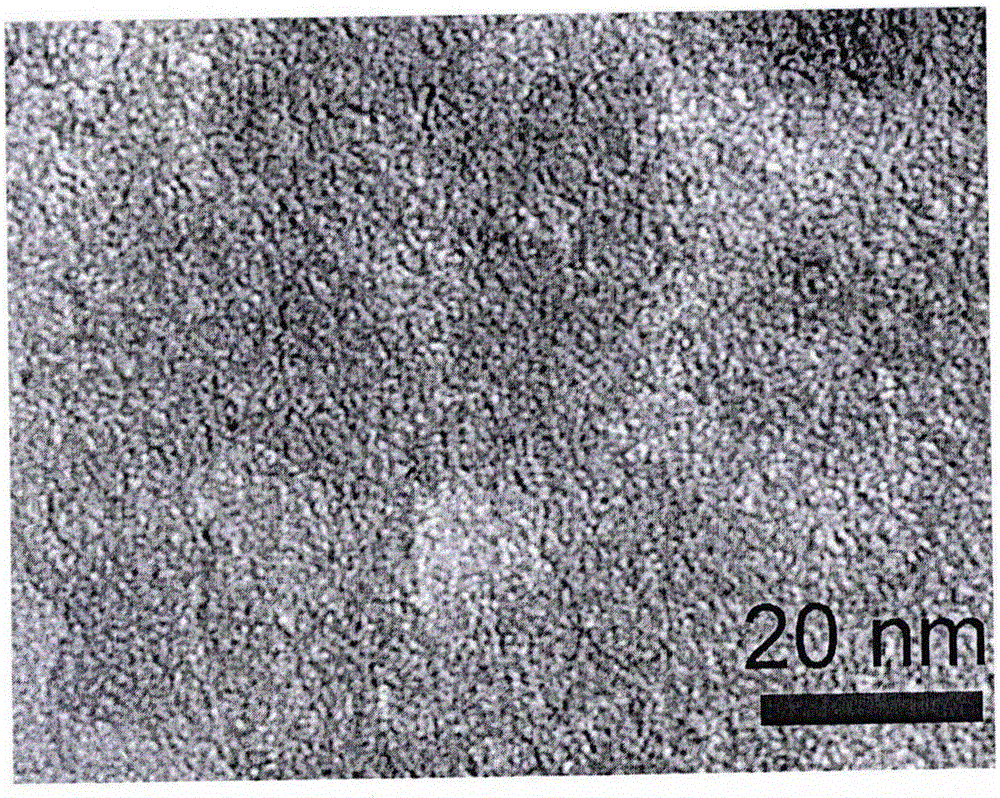

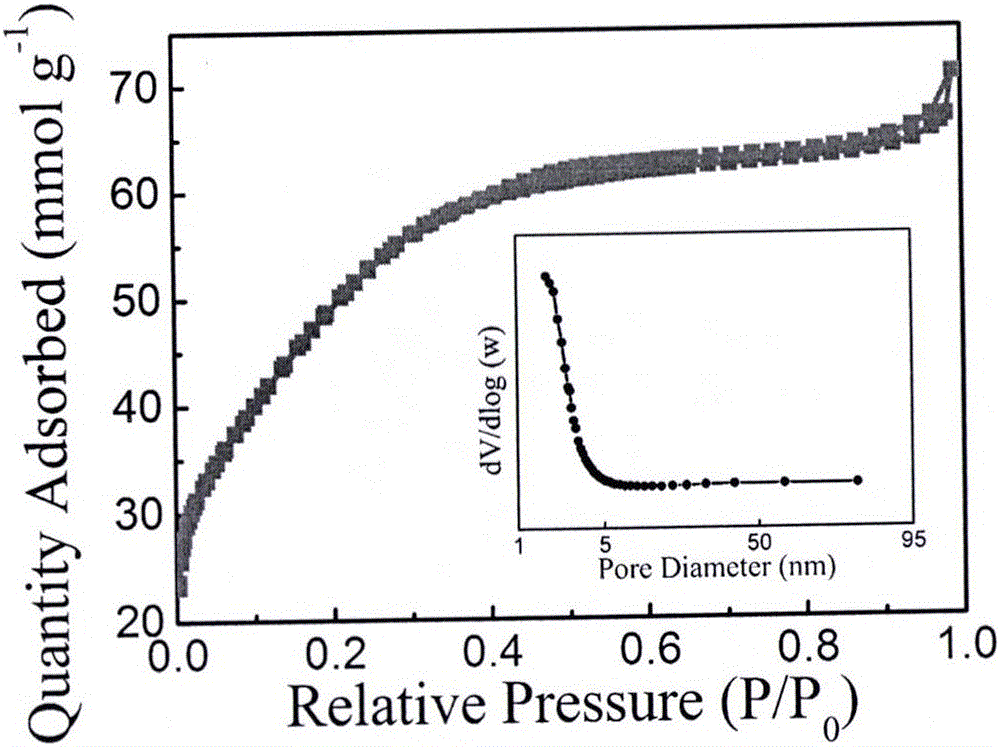

[0023] 1) Drop the iota-type carrageenan aqueous solution with a mass fraction of 2% into the ethanol solution of ferric chloride with a concentration of 1M, wash with deionized water, and prepare a carrageenan-iron hydrogel.

[0024] 2) preparing the carrageenan-iron hydrogel into an aerogel by freeze-drying;

[0025] 3) Carrageenan-iron aerogel is calcined at 400°C for 1 hour in a tube furnace under an argon atmosphere to obtain a carbon aerogel-iron sulfide nanocomposite;

[0026] 4) remove the iron sulfide in the carbon aerogel-iron sulfide nanocomposite material with an aqueous hydrochloric acid solution with a concentration of 2M to obtain the carbon aerogel;

[0027] 5) The carbon aerogel is activated with potassium hydroxide, and the mass ratio of potassium hydroxide to the carbon aerogel is 4:1. The activation process is calcination at 800° C. for 1 hour in a nitrogen atmosphere. Obtain super high specific surface porous carbon deposition airgel;

[0028] 6) The el...

Embodiment 2

[0030] 1) Drop the iota-type carrageenan aqueous solution with a mass fraction of 2% into the ethanol solution of ferric chloride with a concentration of 1M, wash with deionized water, and prepare a carrageenan-iron hydrogel.

[0031] 2) preparing the carrageenan-iron hydrogel into an aerogel by freeze-drying;

[0032] 3) Carrageenan-iron aerogel was calcined at 300°C for 1 hour in a tube furnace under an argon atmosphere to obtain a carbon aerogel-iron sulfide nanocomposite;

[0033] 4) remove the iron sulfide in the carbon aerogel-iron sulfide nanocomposite material with an aqueous hydrochloric acid solution with a concentration of 2M to obtain the carbon aerogel;

[0034] 5) The carbon aerogel is activated with potassium hydroxide, and the mass ratio of potassium hydroxide to the carbon aerogel is 4:1. The activation process is calcination at 800° C. for 1 hour in a nitrogen atmosphere. Obtain super high specific surface porous carbon deposition airgel;

[0035] 6) The e...

Embodiment 3

[0037] 1) Drop the iota-type carrageenan aqueous solution with a mass fraction of 2% into the ethanol solution of ferric chloride with a concentration of 1M, wash with deionized water, and prepare a carrageenan-iron hydrogel.

[0038] 2) preparing the carrageenan-iron hydrogel into an aerogel by freeze-drying;

[0039] 3) Carrageenan-iron aerogel is calcined at 500°C for 1 hour in a tube furnace under an argon atmosphere to obtain a carbon aerogel-iron sulfide nanocomposite;

[0040] 4) remove the iron sulfide in the carbon aerogel-iron sulfide nanocomposite material with an aqueous hydrochloric acid solution with a concentration of 2M to obtain the carbon aerogel;

[0041] 5) The carbon aerogel is activated with potassium hydroxide, and the mass ratio of potassium hydroxide to the carbon aerogel is 4:1. The activation process is calcination at 800° C. for 1 hour in a nitrogen atmosphere. Obtain super high specific surface porous carbon deposition airgel;

[0042] 6) The el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com