Gradient composite structure hierarchical pore thin film and preparation method thereof

A composite structure and multi-level pore technology, applied in chemical instruments and methods, silicon compounds, and other chemical processes, can solve the problems of poor crystallinity and continuity of microporous-mesoporous composite films, insufficient characterization of film pore structures, and persuasive problems. Insufficient power and other problems, to achieve the effect of low cost of goods, excellent continuity, and guaranteed continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

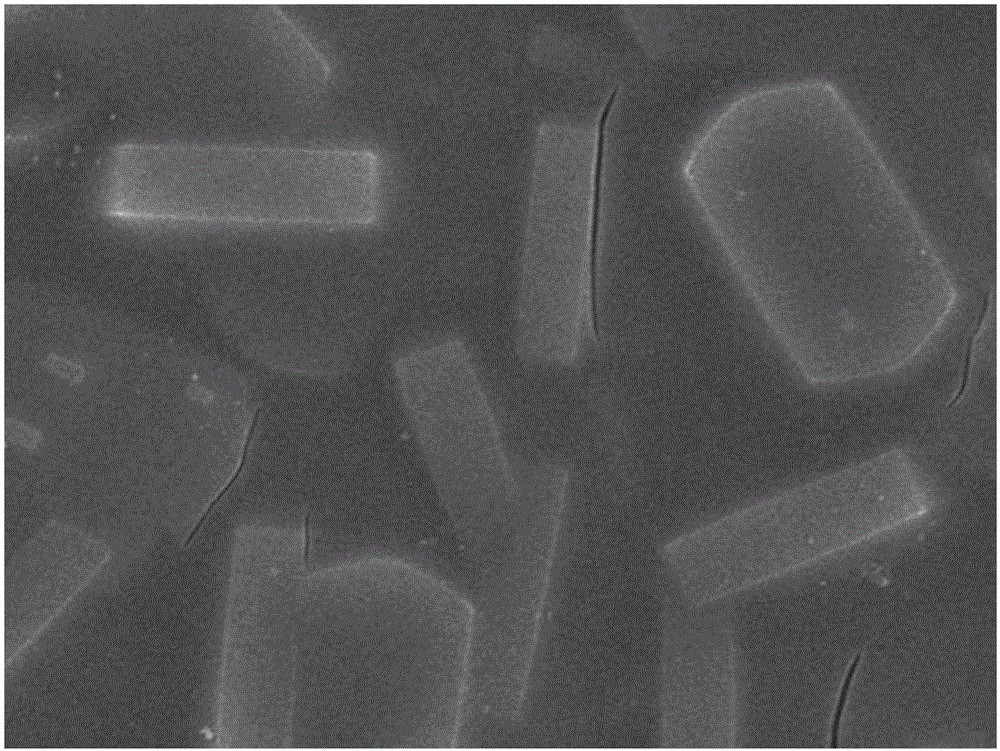

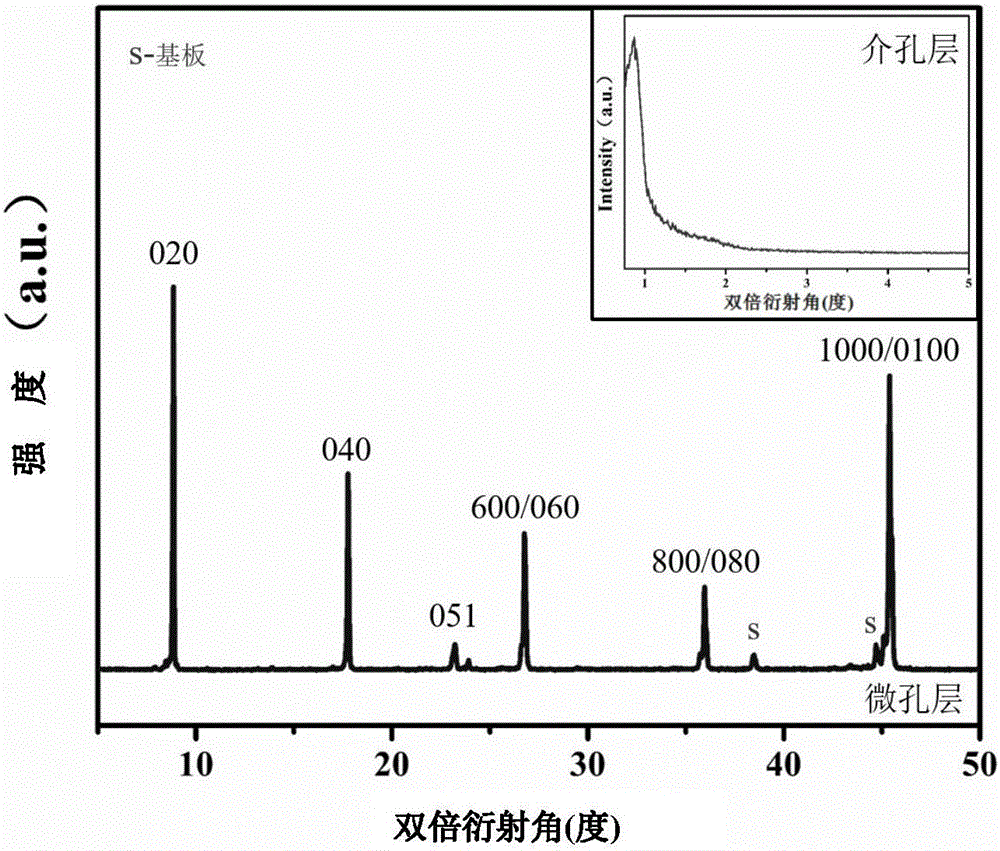

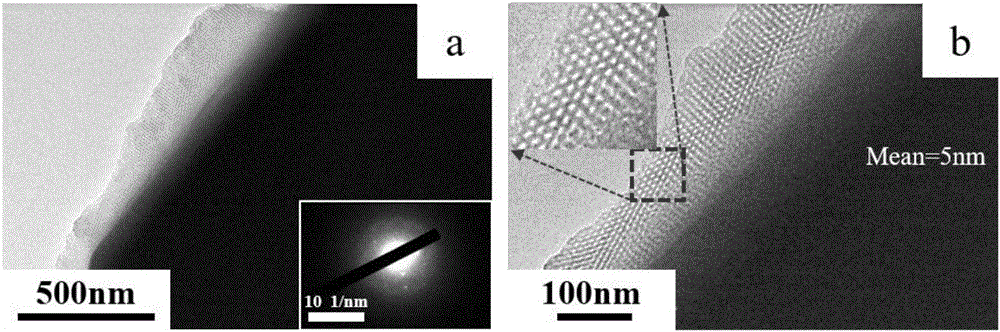

Embodiment 1

[0040] 0.0454g Al(NO 3 ) 3 9H 2 O was dissolved in 36g of water, and 3.88ml of analytically pure tetrapropylammonium hydroxide (TPAOH) and 2.7ml of analytically pure tetraethyl ammonium hydroxide (TEOS) were added successively, and stirred at room temperature for 24h to obtain a solution; the solution was transferred to In a 100ml reaction kettle, vertically immerse the aluminum substrate in the solution, react at 175°C for 4 hours, then cool to room temperature, and then take out the substrate on which the molecular sieve membrane was grown, to obtain the ZSM-5 microporous layer / aluminum substrate.

[0041] First 0.52g of analytically pure F127 (EO 106 PO 70 EO 106 ) was completely dissolved in 20ml of absolute ethanol, marked as 1# solution; 2.225ml of analytically pure TEOS (tetraethyl orthosilicate) was slowly added to 0.21g (1M) hydrochloric acid, 1.455g H 2 O and 10ml of ethanol in a mixed solution, reflux at 70°C for 1h, marked as 2# solution. Then slowly add 1# s...

Embodiment 2

[0048] 0.0454g Al(NO 3 ) 3 9H 2 O was dissolved in 36g of water, and 3.88ml of analytically pure tetrapropylammonium hydroxide (TPAOH) and 2.7ml of analytically pure tetraethyl ammonium hydroxide (TEOS) were added successively, and stirred at room temperature for 24h to obtain a solution; the solution was transferred to In a 100ml reaction kettle, vertically immerse the aluminum substrate in the solution, react at 175°C for 4 hours, then cool to room temperature, and then take out the substrate on which the molecular sieve membrane was grown, to obtain the ZSM-5 microporous layer / aluminum substrate.

[0049] First 0.52g of analytically pure F127 (EO 106 PO 70 EO 106 ) was completely dissolved in 20ml of absolute ethanol, marked as 1# solution; 2.225ml of analytically pure TEOS (tetraethyl orthosilicate) was slowly added to 0.21g (1M) hydrochloric acid, 1.455g H 2 O and 10ml of ethanol in a mixed solution, reflux at 70°C for 1h, marked as 2# solution. Then slowly add 1# s...

Embodiment 3

[0053] 0.0454g Al(NO 3 ) 3 9H 2 O was dissolved in 36g of water, and 3.88ml of analytically pure TPAOH (tetrapropylammonium hydroxide) and 2.7ml of analytically pure TEOS (tetraethylorthosilicate) were added successively, and stirred at room temperature for 24h. The solution was transferred to a 100ml reaction kettle, the aluminum substrate was vertically immersed in the solution, and reacted at 175°C for 4h. After cooling to room temperature, the substrate on which the molecular sieve membrane is grown is taken out to obtain the ZSM-5 microporous layer / aluminum substrate.

[0054] Fix the ZSM-5 microporous layer / aluminum substrate on the jig of the coating puller, assemble the PS colloidal crystal array on its surface, and the PS emulsion concentration is 5wt%. Set the coating program: the dipping / pulling speed is 50mm / min, the dipping time is 3min, and the coating is done once. The samples were dried at 30°C for 1 h.

[0055] 0.52g F127 (EO 106 PO 70 EO 106 ) was com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Maximum aperture | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com