Method for preparing supported cadmium sulfide photocatalyst

A photocatalyst and cadmium sulfide technology, which is applied in the field of photocatalytic materials to achieve the effects of efficient catalytic degradation, good economic benefits and good adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

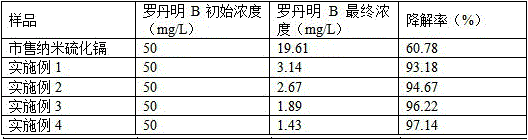

Examples

Embodiment 1

[0023] A preparation method of supported cadmium sulfide photocatalyst, comprising the following steps:

[0024] (1) Weigh each raw material according to the proportion: cadmium nitrate 40g, thiourea 15g, disodium edetate 6g, acrylic acid maleic anhydride copolymer 7g, fly ash 10g, iron porphyrin 2g, indium nitrate 1g and carboxylate Sodium methylcellulose 5g;

[0025] (2) Add cadmium nitrate and thiourea into the ultrasonic generator, add 200mL of water to dissolve them, then add disodium edetate, and continue ultrasonication for 60min at a frequency of 40KHz to obtain a suspension;

[0026] (3) Put the suspension, acrylic acid maleic anhydride copolymer, fly ash, iron porphyrin and sodium carboxymethylcellulose into the ball mill, then add 150mL of water, and stir for 60min at a speed of 300r / min to obtain a paste thing;

[0027] (4) Microwave dry the above paste at 80°C for 2.5h, grind it into a powder with a particle size of 1.0mm after drying, and put it into a horse bo...

Embodiment 2

[0029] A preparation method of supported cadmium sulfide photocatalyst, comprising the following steps:

[0030] (1) Weigh each raw material according to the proportion: cadmium nitrate 50g, thiourea 20g, disodium edetate 8g, acrylic acid maleic anhydride copolymer 5g, fly ash 12g, iron porphyrin 3g, indium nitrate 2g and carboxylate Sodium methylcellulose 8g;

[0031] (2) Add cadmium nitrate and thiourea into the ultrasonic generator, add 250mL of water to dissolve them, then add disodium edetate, and continue ultrasonication for 60min at a frequency of 50KHz to obtain a suspension;

[0032] (3) Put the suspension, acrylic acid maleic anhydride copolymer, fly ash, iron porphyrin and sodium carboxymethylcellulose into the ball mill, then add 150mL of water, and stir for 30min at a speed of 500r / min to obtain a paste thing;

[0033] (4) Microwave dry the above paste at 90°C for 2h, grind it into a powder with a particle size of 1.0mm, put it into a horse boiling furnace and b...

Embodiment 3

[0035] A preparation method of supported cadmium sulfide photocatalyst, comprising the following steps:

[0036] (1) Weigh each raw material according to the proportion: cadmium nitrate 60g, thiourea 25g, edetate disodium 10g, acrylic acid maleic anhydride copolymer 8g, fly ash 15g, cobalt porphyrin 3g, indium nitrate 1.5g and Sodium carboxymethyl cellulose 10g;

[0037] (2) Add cadmium nitrate and thiourea into the ultrasonic generator, add 300mL of water to dissolve them, then add disodium edetate, and continue ultrasonication for 30min at a frequency of 60KHz to obtain a suspension;

[0038] (3) Put the suspension, acrylic acid maleic anhydride copolymer, fly ash, cobalt porphyrin and sodium carboxymethylcellulose into the ball mill, then add 150mL of water, and stir for 45min at a speed of 400r / min to obtain a paste thing;

[0039] (4) Microwave dry the above paste at 100°C for 1.5h, grind it into a powder with a particle size of 2.0mm after drying, and then put it into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com