Method for preparing negative electrode material lithium titanate of lithium battery through spray freeze drying

A technology of spray freeze-drying and negative electrode materials, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of unsatisfactory electrochemical performance, lithium dendrite short circuit, poor conductivity, etc., and achieve excellent high rate discharge characteristics, particle size Uniform distribution and improved conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

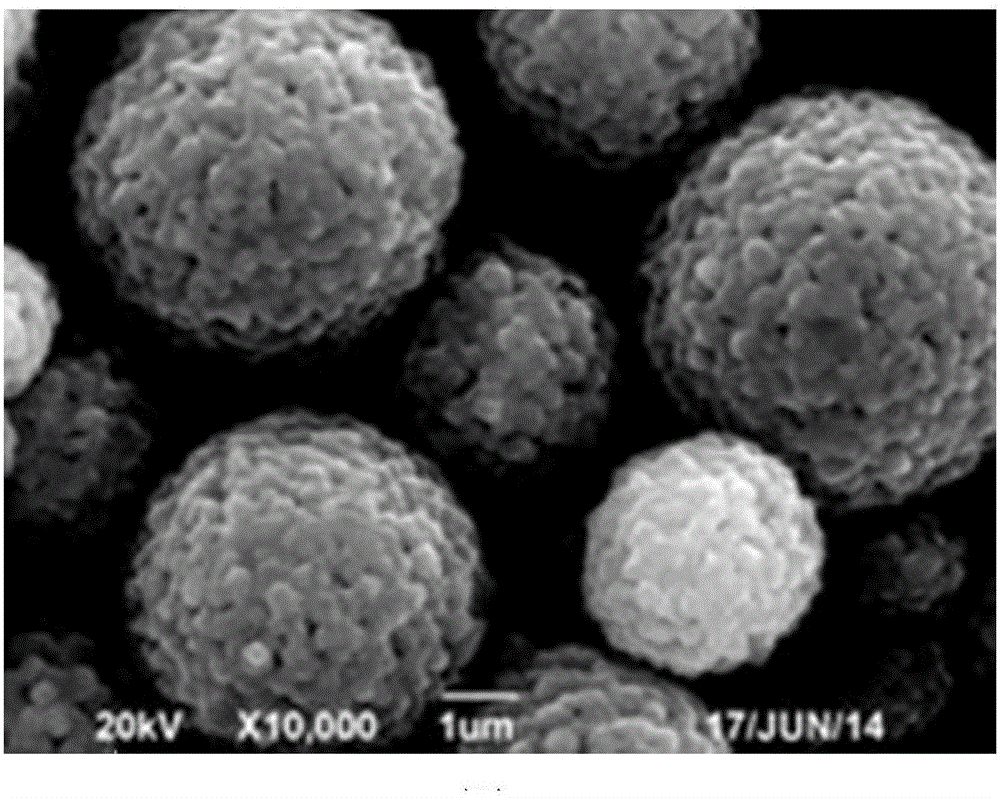

[0021] According to the molar ratio Li: (Ti+Nb) = 0.805, Ti: Nb = 4.95: 0.05, weigh Li 2 CO 3 , rutile TiO 2 , Nb 2 o 5 Mix evenly and disperse in distilled water with a solid content of 20%. Transfer the dispersed slurry to a sand mill and grind it for 1 hour, then spray the slurry into a mixture of liquid nitrogen and liquid propane at a volume ratio of 1:1.5. A frozen product is produced in the refrigerant, and the frozen product is vacuum freeze-dried at -60°C for 18 hours to sublimate and disappear the water in the product to obtain a porous spherical lithium titanate precursor. The precursor is placed in an atmosphere furnace under an air atmosphere for 400 After pre-firing at ℃ for 5 hours, switch to nitrogen atmosphere and sinter at 800℃ for 9 hours to obtain the target product porous spherical lithium titanate negative electrode material: Li 4 Nb 0.05 Ti 4.95 o 12 Such as figure 1 shown.

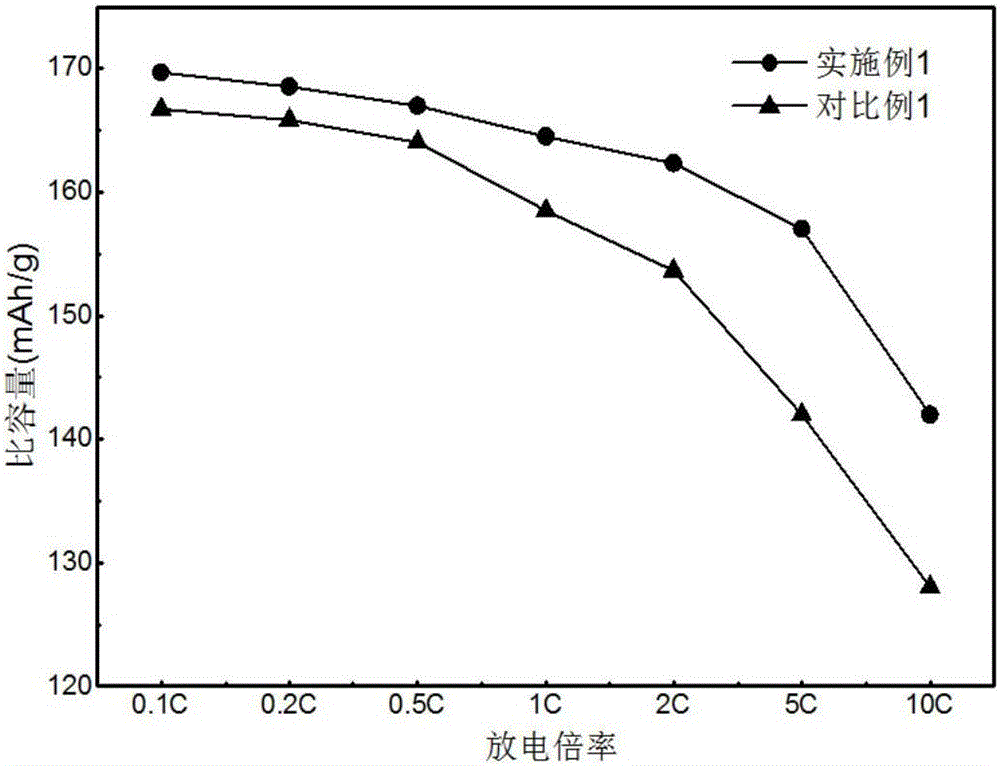

[0022] A 2032 button battery composed of the material in Example 1 and...

Embodiment 2

[0024] According to the molar ratio Li: (Ti+Nd) = 0.82, Ti: Nd = 4.95: 0.05, weigh Li 2 CO 3 , rutile TiO 2 、Nd 2 o 3 Mix evenly and disperse in distilled water with a solid content of 18%. Transfer the dispersed slurry to a sand mill and grind it for 0.5h, then spray the slurry into liquid nitrogen and liquid propane to mix in a volume ratio of 1:2 A frozen product is produced in the refrigerant, and the frozen product is vacuum freeze-dried at -50°C for 16 hours to sublimate and disappear the water in the product to obtain a porous spherical lithium titanate precursor, which is placed in an atmosphere furnace under an air atmosphere Pre-fired at 435°C for 4 hours, then switched to sintering at 775°C for 8 hours under nitrogen atmosphere to obtain the target product porous spherical lithium titanate negative electrode material: Li 4 Nd 0.05 Ti 4.95 o 12 .

[0025] A 2032 button battery composed of the material of Example 2 and metal lithium sheets was tested at 25°C b...

Embodiment 3

[0027] According to molar ratio Li: (Ti+V) = 0.80, Ti: V = 4.95: 0.06, weigh Li 2 CO 3 , rutile TiO 2 , V 2 o 5 Mix evenly and disperse in distilled water with a solid content of 25%. Transfer the dispersed slurry to a sand mill and grind for 1.5 hours, then spray the slurry into liquid nitrogen and liquid propane to mix at a volume ratio of 1:1 The frozen product is produced in the refrigerant, and the frozen product is vacuum freeze-dried at -40°C for 20 hours to sublimate and disappear the water in the product to obtain a porous spherical lithium titanate precursor, which is placed in the atmosphere furnace under the air atmosphere After pre-calcining at 400°C for 4 hours, switch to nitrogen atmosphere and sinter at 850°C for 8 hours to obtain the target product porous spherical lithium titanate negative electrode material: Li 4 V 0.06 Ti 4.94 o 12 .

[0028] A 2032 button battery composed of the material of Example 3 and metal lithium sheets was tested at 25°C by a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com