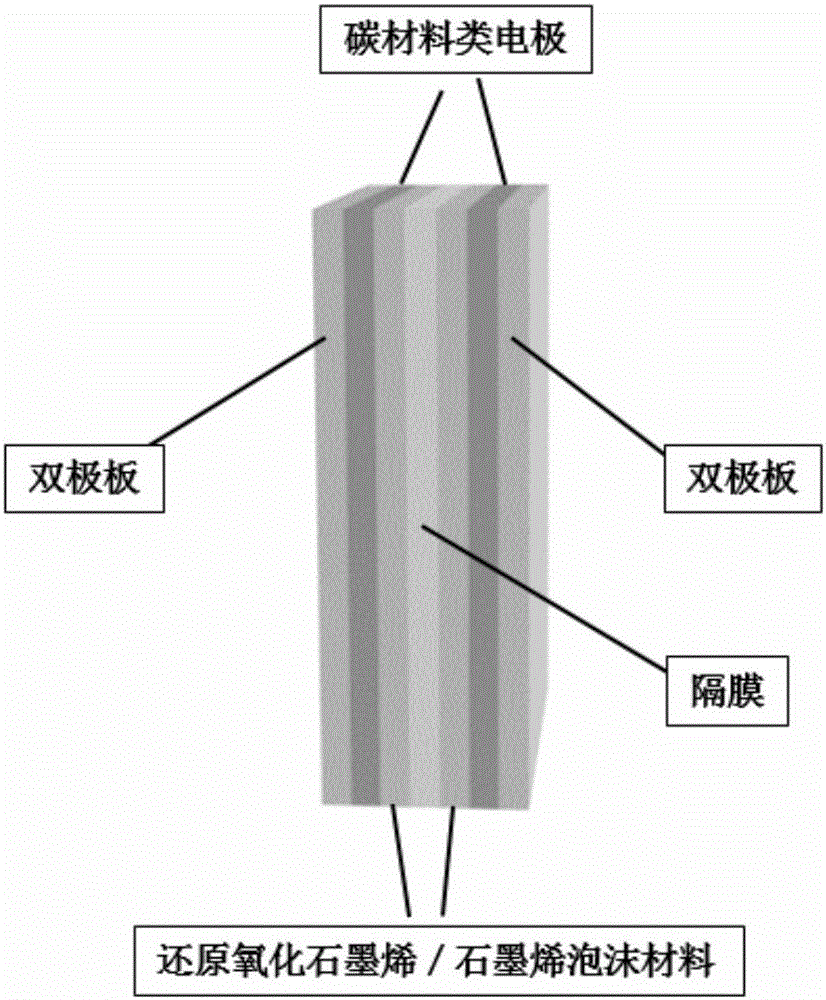

Oxygen-containing functional group gradient distribution reduced graphene oxide/graphene foam composite and application thereof to vanadium redox batteries

A technology of graphene foam and gradient distribution, applied in the direction of regenerative fuel cells, battery electrodes, circuits, etc., can solve the problems of excellent physical properties of destructible carbon fibers, limited electrochemical activity of graphitized carbon felt, low surface activity of graphitized carbon felt, etc. problems, to achieve the effect of improving electrocatalytic activity and electrochemical reversibility, improving energy efficiency and cycle life, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

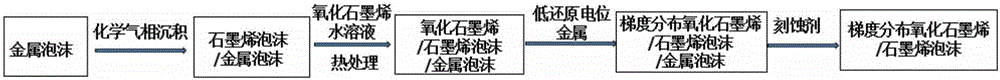

[0032] (1) Preparation of three-dimensional graphene foam / porous metal: On the surface of nickel foam or copper foam porous metal, graphene is grown by chemical vapor deposition to obtain three-dimensional graphene foam / porous metal;

[0033] (2) Preparation of graphene oxide / graphene foam / porous metal structure with gradient distribution of oxygen-containing functional groups: immerse graphene foam / porous metal in graphene oxide aqueous solution, heat treatment, and then place it on a metal with low reduction potential After reduction and freeze-drying, a graphene oxide / graphene foam / porous metal structure with a gradient distribution of oxygen-containing functional groups is obtained;

[0034] (3) Dissolution of porous metal: remove the porous metal with a porous metal etching solution, and obtain a graphene oxide / graphene foam structure with a gradient distribution of oxygen-containing functional groups after freeze-drying;

[0035] In the preparation method of the reduced ...

Embodiment 1

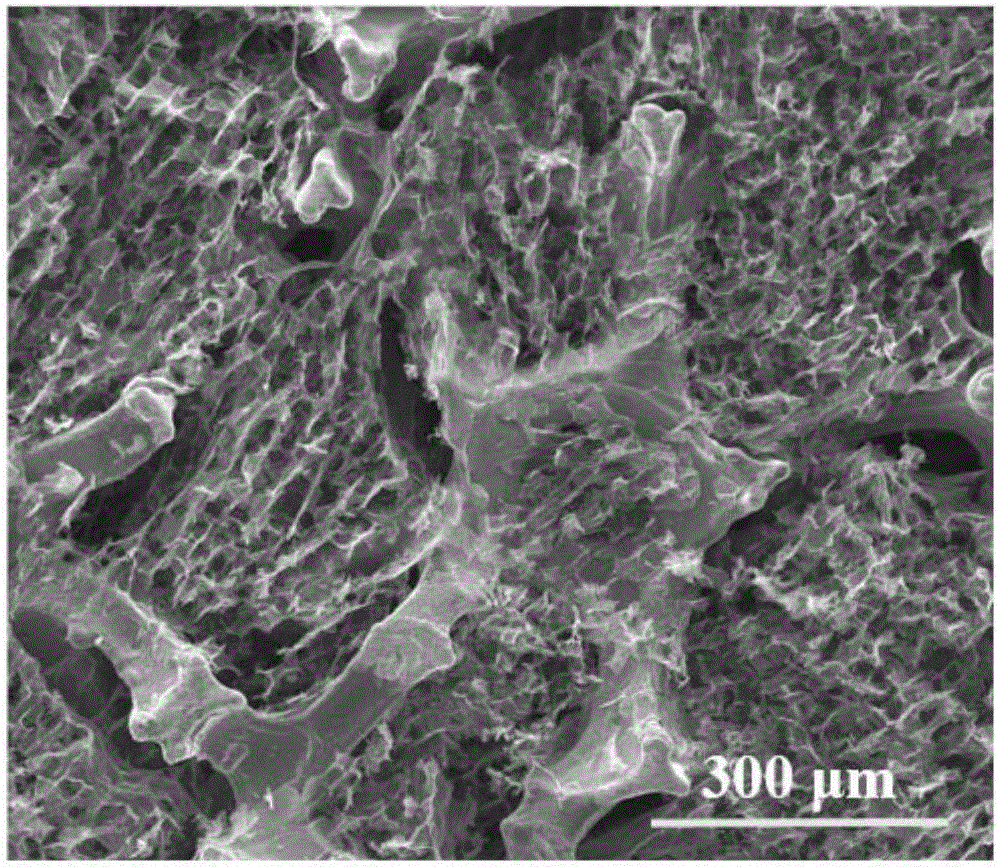

[0042] Such as figure 1 Shown, nickel foam is used as template (30 millimeters * 30 millimeters * 1.4 millimeters), adopt chemical vapor deposition method, obtain the foamed nickel of surface coating graphene, the surface density of the graphene foam that obtains is 1.5mg / cm 2 .

[0043] The graphene foam / nickel foam (9cm 2 ) is immersed in a graphene oxide aqueous solution with a concentration of 6mg / mL and pH=4 for processing, the treatment temperature is 60°C, and the time is 24h to obtain graphene oxide / graphene foam / nickel foam, wherein the surface density of graphene oxide is 1.5mg / cm 2 . Then it was placed on zinc metal for reduction for 0.5 h, and after freeze-drying, a graphene oxide / graphene foam / porous metal structure with a gradient distribution of oxygen-containing functional groups was obtained. Put into 3mol / L hydrochloric acid solution, react at 80 ℃ of temperature for 12h to dissolve nickel foam, wash repeatedly with deionized water, finally obtain the red...

Embodiment 2

[0046] The difference between Example 2 and Example 1 lies in the metal sheet of the reduced graphene oxide. First, nickel foam is used as a template (30 mm × 30 mm × 1.4 mm), and the chemical vapor deposition method is used to obtain nickel foam coated with graphene on the surface. The surface density of the graphene foam obtained is 1.5 mg / cm 2 .

[0047] Graphene foam / nickel foam (9cm 2 ) is immersed in a graphene oxide aqueous solution with a concentration of 4mg / m and pH=4 for processing, the treatment temperature is 60°C, and the time is 24h to obtain graphene oxide / graphene foam / nickel foam, wherein the surface density of graphene oxide is 1.0mg / cm 2 . Then it was placed on chromium metal with a low reduction potential for reduction for 0.5 h, and after freeze-drying, a graphene oxide / graphene foam / porous metal structure with a gradient distribution of oxygen-containing functional groups was obtained. Put it into 3mol / L hydrochloric acid solution, react at 80°C for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com