Treatment method for high ammonia nitrogen landfill leachate

A high-ammonia-nitrogen garbage and landfill leachate technology, applied in the field of sewage treatment, can solve the problems of difficult disposal, difficult to guarantee the effect, and high energy consumption, and achieve the effects of reducing total hardness and alkalinity, maintaining stability, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

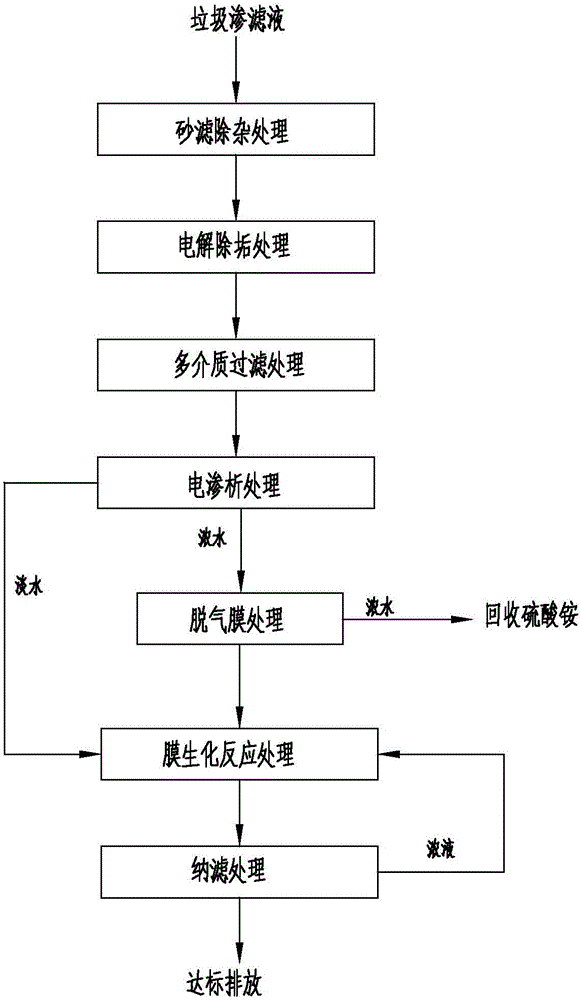

Method used

Image

Examples

Embodiment 1

[0039] The treatment of the present invention is used to treat the leachate of a certain landfill. The landfill has been buried for a long time, and its leachate has begun to "aging", and the carbon-nitrogen ratio has been reduced to 2:1. The water quality of the leachate was tested, and the specific water quality conditions are shown in Table 2.

[0040] Table 2

[0041] water quality index

pH

COD

BOD

Ammonia nitrogen

SS

total hardness

TDS

Valuemg / L

6-9

5000

1500

2500

2800

1000

5000

10000

[0042] Send the leachate into the sand filter. The particle size of the quartz sand in the sand filter is 0.5-1.5mm. After the sand filter removes impurities, the water quality is tested according to GB16889-2008. The solids in the treated leachate raw water are The removal rate of suspended matter SS is 95%, the removal rate of COD is 5%, the removal rate of BOD is 5%, the removal rate of ammonia ...

Embodiment 2

[0050] Most of the incoming garbage in a landfill site is organic matter and nitrogen compounds. The leachate has a high concentration of organic matter, and the carbon-nitrogen ratio is reduced to 2:1. The water quality is shown in Table 3.

[0051] table 3

[0052] water quality index

pH

COD

BOD

Ammonia nitrogen

SS

total hardness

TDS

Valuemg / L

6-9

10000

4000

5000

5500

1000

3000

12000

[0053] Send the leachate into the sand filter. The particle size of the quartz sand in the sand filter is 0.5-1.5mm. After the sand filter removes impurities, the water quality is tested according to GB16889-2008. After the treatment, the SS in the raw water of the leachate is removed. The removal rate of COD is 6%, the removal rate of BOD is 6%, the removal rate of ammonia nitrogen is 3%, the removal rate of total nitrogen is 4%, the TDS is 10000mg / L, and the turbidity drops below 1NTU.

[0054] The l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com