Wood-imitating profile prepared through glass fiber reinforced plastic waste regeneration and preparation process thereof

A fiberglass and imitation wood technology, applied in the field of imitation wood profiles and its preparation process, can solve the problems of plate surface strength, poor wear resistance, complex manufacturing process, etc., and achieve the advantages of avoiding migration, large specific surface area, and enhanced structural thermal stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] (1) Preparation of foam masterbatch

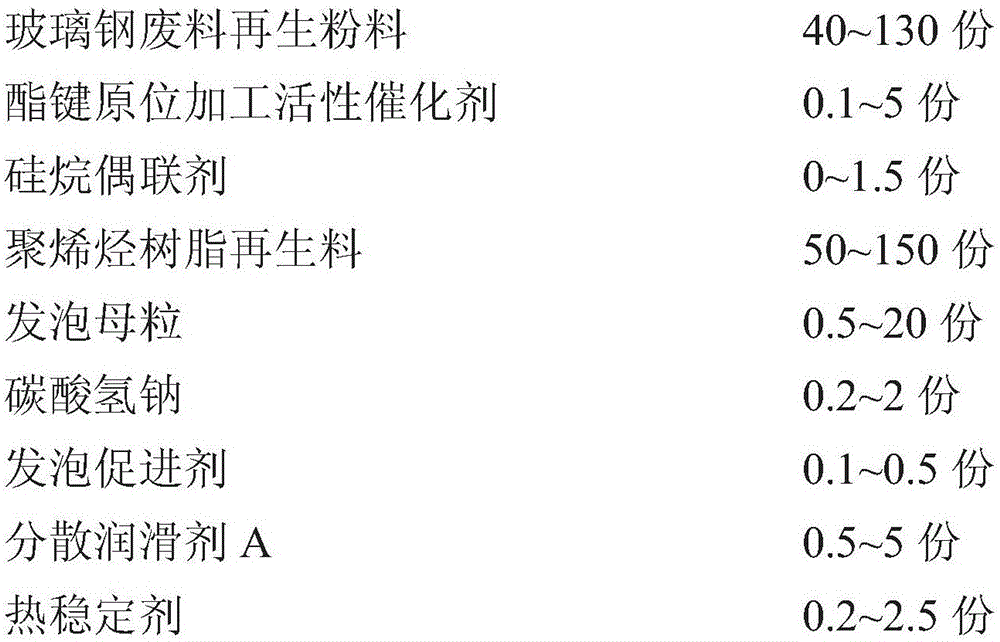

[0051] In parts by weight, the foam masterbatch includes the following components:

[0052]

[0053] POE3300 is American Dow ENGAGE 3300TPO, its melt flow rate: 0.5g / 10min, density: 0.87g / cm 3 .

[0054] Extrude with a twin-screw extruder produced by Nanjing Keya Chemical Complete Equipment Co., Ltd. according to the above formula, and air-cooled granulate to obtain foam masterbatch;

[0055] (2) Core molding

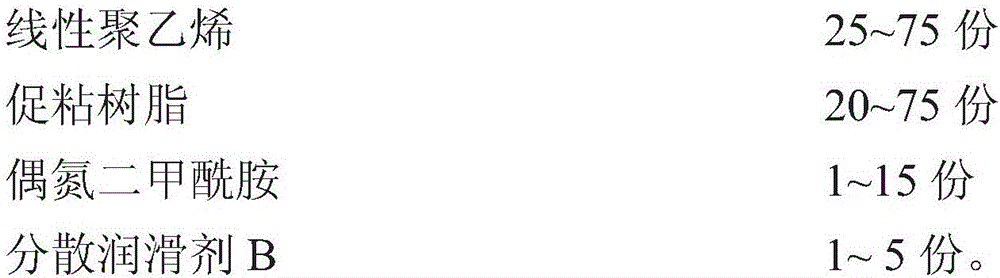

[0056] In parts by weight, the core material includes the following components:

[0057]

[0058] The FRP waste used in this embodiment is the decommissioned wind power blade FRP material provided by Jilin Zhongtong Chengfei New Material Co., Ltd.

[0059] After being cut, the FRP waste is crushed with a FRP twin-shaft shredder from Changshu Shouyu Machinery Co., Ltd., and then finely crushed and coarsely separated by a cyclone with an airflow vortex classifier from Shengzhou Guanqi Crushing Machinery Technology Co....

Embodiment 2

[0070] (1) Preparation of foam masterbatch

[0071] In parts by weight, the foam masterbatch includes the following components:

[0072]

[0073] EVA550 is produced by Mitsui Chemicals, Japan, its melt flow rate: 15g / 10min, density: 0.93g / cm 3 .

[0074] Extrude with a twin-screw extruder produced by Nanjing Keya Chemical Complete Equipment Co., Ltd. according to the above formula, and air-cooled granulate to obtain foam masterbatch;

[0075] (2) Core molding

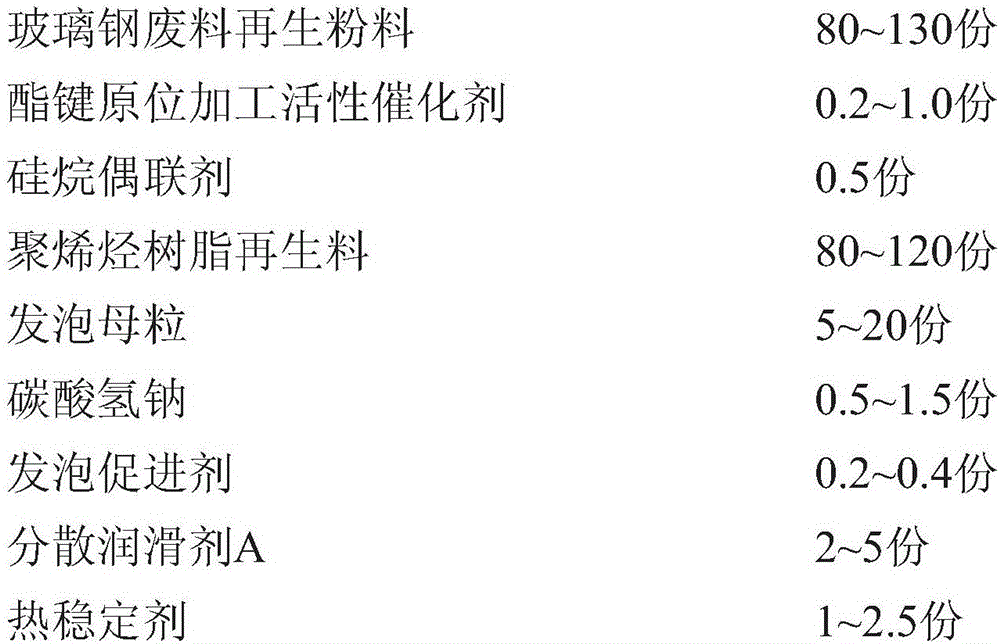

[0076] In parts by weight, the core material includes the following components:

[0077]

[0078] The FRP waste used in this embodiment is the decommissioned wind power blade FRP material provided by Jilin Zhongtong Chengfei New Material Co., Ltd.

[0079] After being cut, the FRP waste is crushed with a FRP twin-shaft shredder from Changshu Shouyu Machinery Co., Ltd., and then finely crushed and coarsely separated by a cyclone with an airflow vortex classifier from Shengzhou Guanqi Crushing Machinery Technolo...

Embodiment 3

[0090] (1) The preparation of the foam masterbatch is as in Example 2.

[0091] (2) Core molding is as in Example 2.

[0092] (3) Preparation of imitation wood profiles

[0093] In this example, self-produced polyethylene terephthalate (PET) heat-shrinkable tubes are selected. The outer diameter of the tube is 190mm, the wall thickness is 1.2mm, the shrinkage ratio is 1.5 / 1, and the shrinkage temperature is 150-250°C.

[0094] (3.1) Casing

[0095] The above-mentioned polymer heat-shrinkable tube is set outside the core material, and the heat-shrinkable tube shrinks and clings to the surface of the core material by heating the sleeve to obtain a wood-like profile blank.

[0096] (3.2) Heating and shaping

[0097] The wood-like profile blank conveyor belt enters the heating zone to preheat and heat up, heat the core material to a temperature of 155-165°C, control the surface temperature of the heat-shrinkable tube to be higher than the deformation temperature through the pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com