Polypropylene/liquid crystal elastomer/fullerene composite cable material and preparation method thereof

A technology of liquid crystal elastomer and composite cable material, applied in the direction of insulated cables, cables, conductors, etc., can solve the problem that the comprehensive performance cannot meet the needs of the market, and achieve the effects of excellent mechanical properties, improved light resistance, and good thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

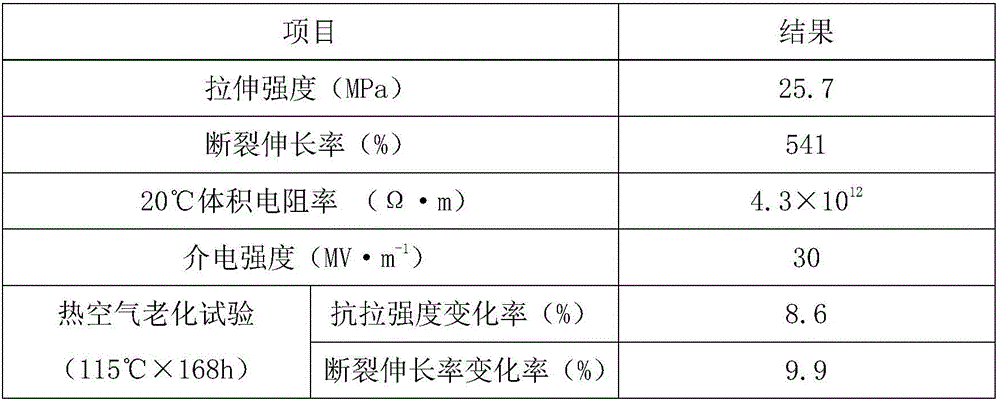

Image

Examples

Embodiment Construction

[0011] A polypropylene / liquid crystal elastomer / fullerene composite cable material, made of the following raw materials by weight (kg): polypropylene 43, liquid crystal elastomer 29, fullerene 26, white oil 9, phthalate di Isononyl ester 12, silica fume 18, pyrolusite powder 7, power plant slag 11, calcium stearate 2.5, zinc stearate 1.5, polytetrafluoroethylene fine powder wax 9, dichloroethylaluminum 6, triisooctyl borate 12. Shuangfei powder 13. Andalusite 19.

[0012] A preparation method of polypropylene / liquid crystal elastomer / fullerene composite cable material, comprising the following steps:

[0013] (1) Mix silica fume, power plant slag, andalusite evenly, crush, sieve, and calcinate at 720-780°C for 1-2h, after cooling to room temperature, add the calcined powder to the mass according to the solid-liquid ratio 1:5-7 In a sulfuric acid solution with a fraction of 30%, heat it in a water bath to 50-60°C, soak in heat for 2-3 hours, let it stand and cool, then filter,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com