Anti-static light-cured resin material for 3D (three-dimensional) printing

A light-curing resin and 3D printing technology, applied in the direction of additive processing, etc., can solve the problems of antibacterial, antifouling and self-cleaning functions, low impact resistance, enrichment of pollutants, etc., and achieve good antistatic effect, Effects of improving performance and widening the range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

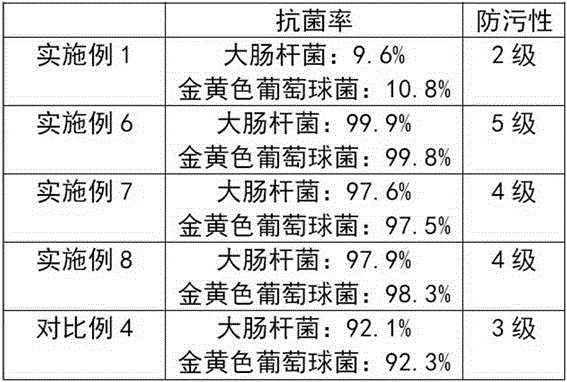

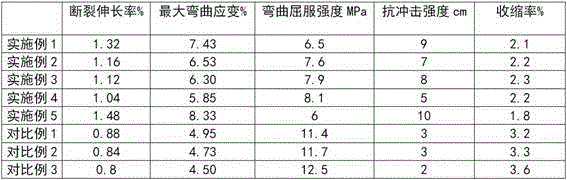

Examples

preparation example Construction

[0014] (1) Preparation of epoxy acrylic resin: Weigh a certain amount of epoxy resin, dissolve it in toluene solvent, stir to dilute the solution, pour it into a three-necked flask, heat and stir in an oil bath at 90°C, and make it Fully dissolve; in addition, accurately measure a certain amount of acrylic acid and place it in a beaker, and add N,N-xylidine and hydroquinone to make an acrylic acid system. In epoxy resin, react stably for 1 hour, then gradually raise the temperature to 95°C, and react for another 1 hour; after the reaction, the product is suction filtered and cooled to room temperature to obtain a light yellow transparent colloidal liquid, namely epoxy acrylic resin; The mass ratio of resin to acrylic acid is 2.5:1, the mass ratio of N,N-xylidine to inhibitor hydroquinone is 1:3, and the mass ratio of N,N-xylidine to epoxy resin is 1 :12.

[0015] (2) Graphene is prepared by the following method: take a certain amount of graphite, treat it in the air at 1000 °...

Embodiment 1

[0020] A photocurable resin material for 3D printing, which consists of the following raw materials in parts by weight: 80 parts of epoxy acrylic resin, 2 parts of reactive diluent, 1 part of photoinitiator, 2 parts of other auxiliary agents, and 3 parts of graphene and 2 parts of multi-walled carbon nanotubes.

[0021] The preparation method of the photocurable resin material used for this 3D printing is as follows:

[0022] (1) Surface treatment of graphene and multi-walled carbon nanotubes with silane coupling agent KH550 or YDH-42 respectively;

[0023] (2) Weigh epoxy acrylic resin, add trimethylolpropane triacrylate, fully stir the system until it is diluted, and adjust the viscosity of the system to about 12 centipoise. Mix evenly; add benzoin dimethyl ether and isopropyl thioxanthone to the solution obtained in step (1), put it in a water bath and heat up to dissolve, and stir thoroughly, until all the solid particles are dissolved, stop stirring, and cool to room tem...

Embodiment 2

[0025] Based on Example 1, the difference is that the weight ratio of the epoxy acrylic resin, graphene and multi-walled carbon nanotubes is 80:5:8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com