Plant essential oil with antibacterial effect as well as preparation method and application thereof

A technology for plant essential oils and plant raw materials, applied in the directions of essential oils/spices, fat production, etc., can solve the problems of backward separation and extraction technology, complicated separation and drying operations, low oil yield by pressing method, etc., to shorten the extraction time and simplify the process. Easy to operate, improve extraction efficiency and extraction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

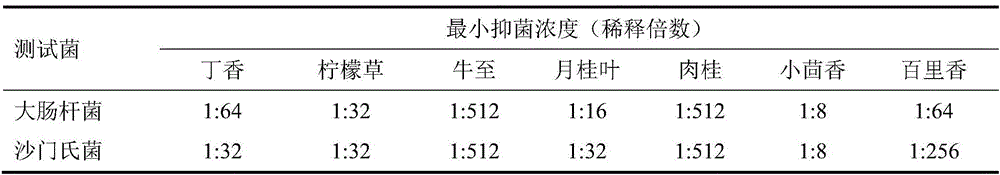

[0092] Embodiment 1, the antibacterial effect comparison of different plant raw material essential oil extracts

[0093] 1) Clove, lemongrass, oregano, bay leaf, cinnamon, cumin, thyme and other plant materials rich in phenolic plant essential oils are respectively crushed and passed through a 50-mesh sieve. Weigh 100g of the raw material powder into a 2000mL round-bottomed flask, add 800mL of water, that is, make the material-liquid ratio of the crushed plant material to water 1g:8mL, and soak for 1h. Then place the round-bottomed flask on the heating mantle and heat it slowly until slightly boiled, steam distilled for 6 hours, collect the distilled liquid into the water separator through the condenser tube, and release the essential oil in the upper layer through the cock of the water separator to obtain the plant essential oil extract .

[0094] 2) Dilute the plant essential oil extract obtained in step 1) to 1:1, 1:2, 1:4, 1:8, 1:16, 1:32 with sterile water (95% ethanol s...

Embodiment 2

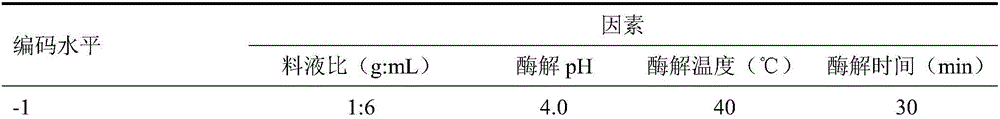

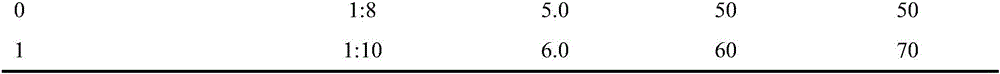

[0099] Embodiment 2, the influence of enzymolysis condition on plant essential oil extraction yield

[0100] 1) According to Example 1, select the top three plants with the antibacterial effect obtained, use crushed cinnamon, oregano, and thyme to form the source of raw materials at a ratio of 1:1:1, add normal temperature water, and then add enzymes, every 100g of raw materials (crushed The mixed raw material of cinnamon, oregano and thyme) is added 1g of mixed enzyme composed of papain, cellulase and pectinase at a ratio of 1:1:1, wherein the enzymes of papain, cellulase and pectinase The activity is 12U / mg, 0.8U / mg and 1.0U / mg respectively, and the enzymolysis is carried out under certain conditions to obtain the enzymolysis solution. According to the author's research, four factors, such as solid-liquid ratio, enzymatic hydrolysis pH, enzymatic hydrolysis temperature and enzymatic hydrolysis time, which have a great influence on the extraction rate of plant essential oils,...

Embodiment 3

[0111] Embodiment 3, the influence of extraction temperature on subcritical water extraction plant essential oil yield

[0112] 1) Use crushed and sieved cinnamon, oregano, and thyme as a source of raw materials at a ratio of 1:1:1, add room temperature water, and then add enzymes. Add 1g of a mixed enzyme consisting of papain, cellulase and pectinase at a ratio of 1:1:1, wherein the enzyme activities of papain, cellulase and pectinase are 12U / mg, 0.8U / mg and 1.0 U / mg, carry out enzymatic hydrolysis under certain conditions to obtain enzymatic hydrolysis solution. Enzymolysis was carried out according to the optimal enzymolysis conditions in Example 2, that is: the solid-liquid ratio of the crushed plant mixed raw material to normal temperature water was 1g:8mL, the pH value of the enzymolysis was 6.0, and the enzymolysis temperature was 40°C. The time is 50 minutes. Obtain enzymatic solution.

[0113] 2) centrifuging the mixed solution after enzymolysis in step 1) under a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com